Multistage variable-rigidity pneumatic soft actuator

A variable stiffness and actuator technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of small stiffness variation range, poor load capacity, slow response speed, etc., and achieve small size, wide load range, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing and embodiment:

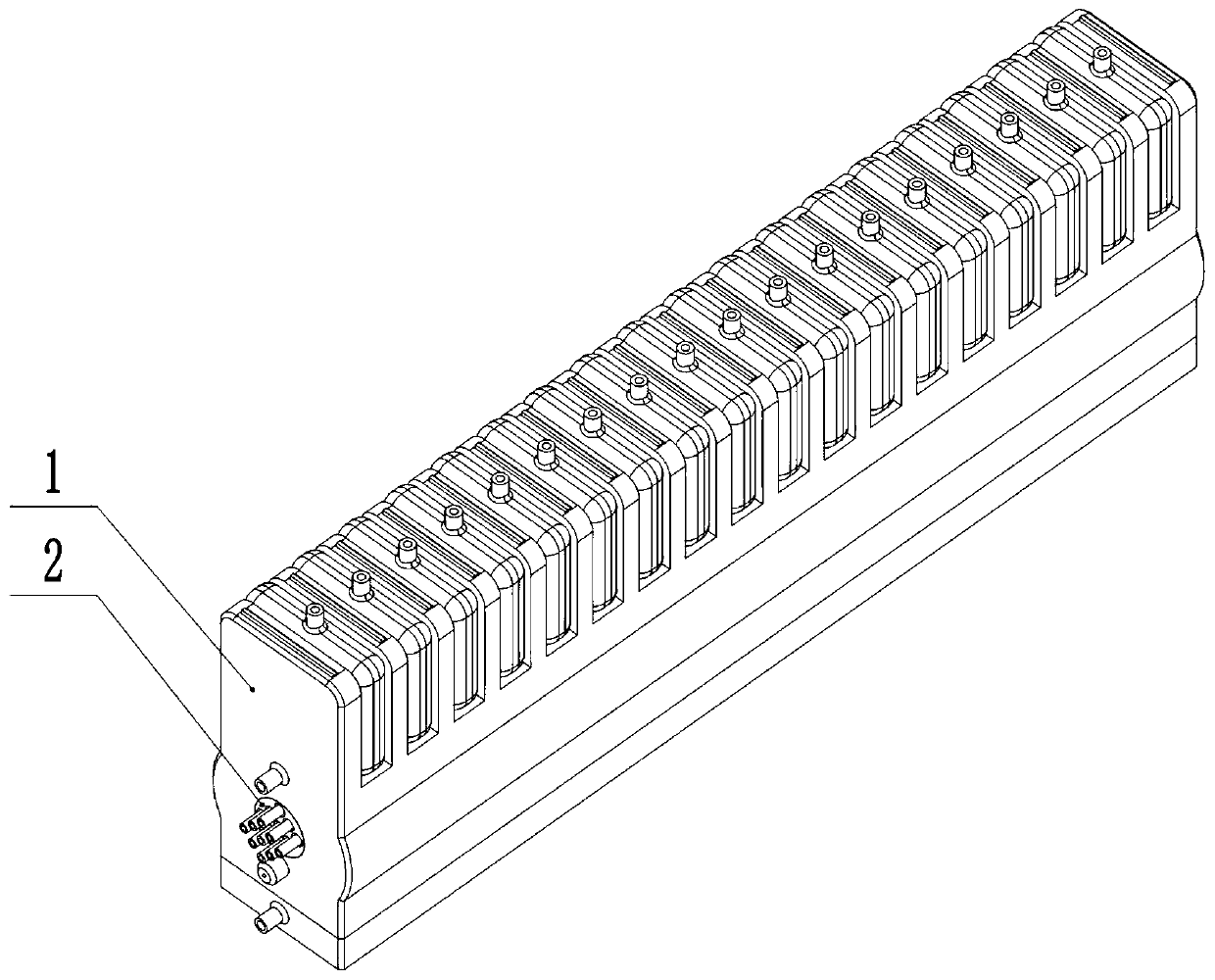

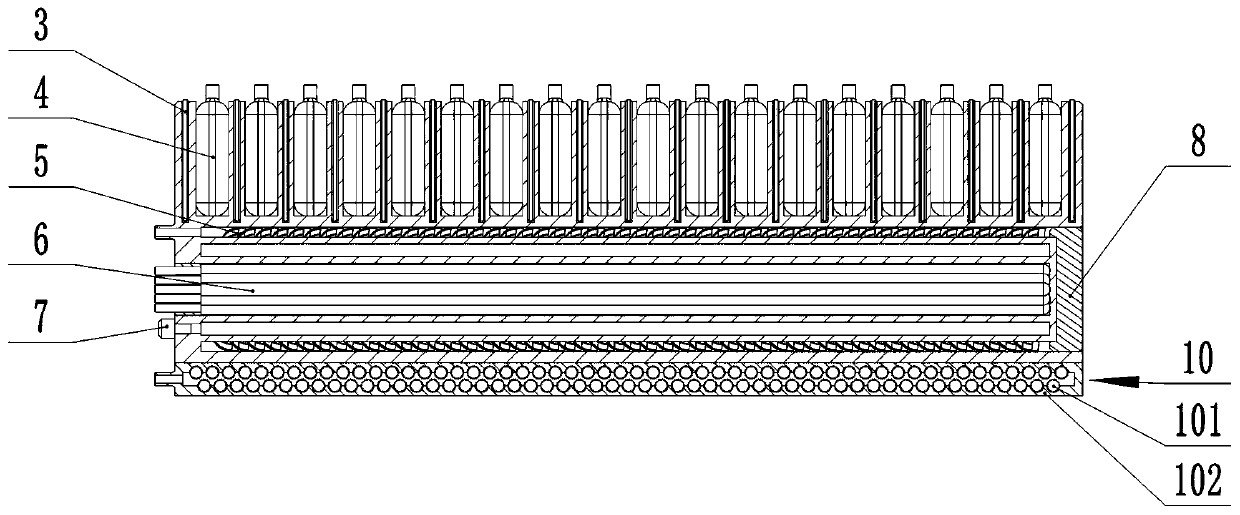

[0025] see Figure 1 to Figure 7 As shown, a multi-stage variable stiffness pneumatic soft actuator includes a first soft frame 1, a first end cover 2, a hard baffle 3, an air bag 4, a contact type helical elastic variable stiffness element 5, a pneumatic tubular variable Stiffness element 6 , dustproof ventilation plug 7 , second end cover 8 , contact tooth deformation stiffness module 10 .

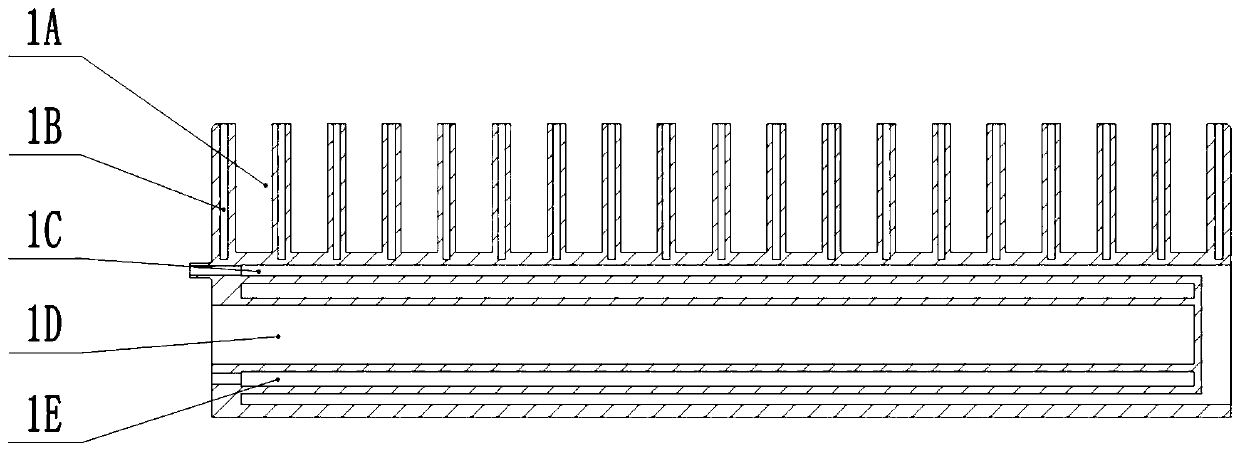

[0026] Among them, the top of the first software frame 1 is provided with a plurality of U-shaped grooves 1A arranged in parallel, and a plurality of independently driven airbags 4 are fixed in the U-shaped grooves 1A on the first software frame 1 for driving the actuators. A vertical slot 1B is provided in the partition between the two U-shaped slots 1A, and a hard baffle 3 is fixed in the slot 1B in order to allow the driven airbag 4 to achieve a better ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com