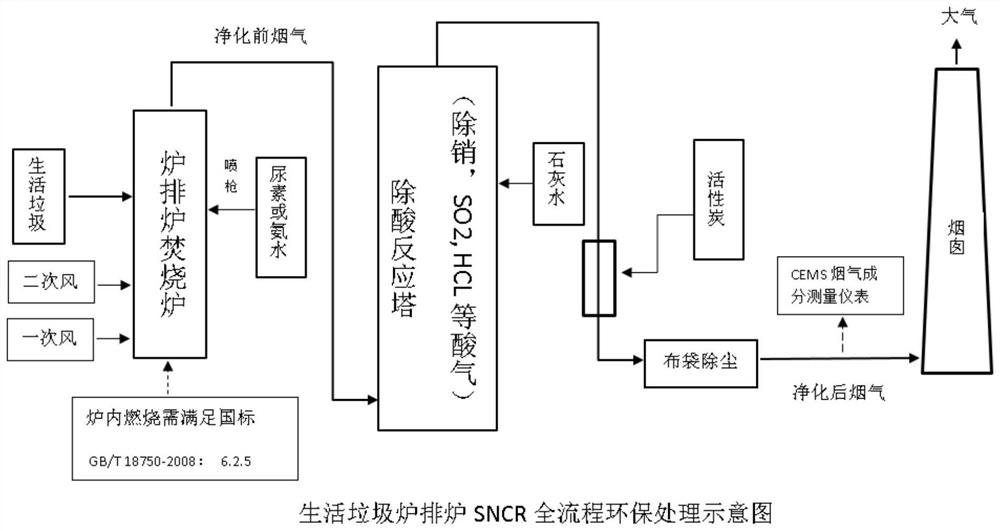

A whole-process monitoring system for grate furnace waste incineration and discharge

A waste incineration and monitoring system technology, applied in the field of pollutant discharge, can solve the problems of being unable to determine whether the pollutants in the flue gas emission are actually up to the standard, unable to trace the source, and unable to provide operation prompts for staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

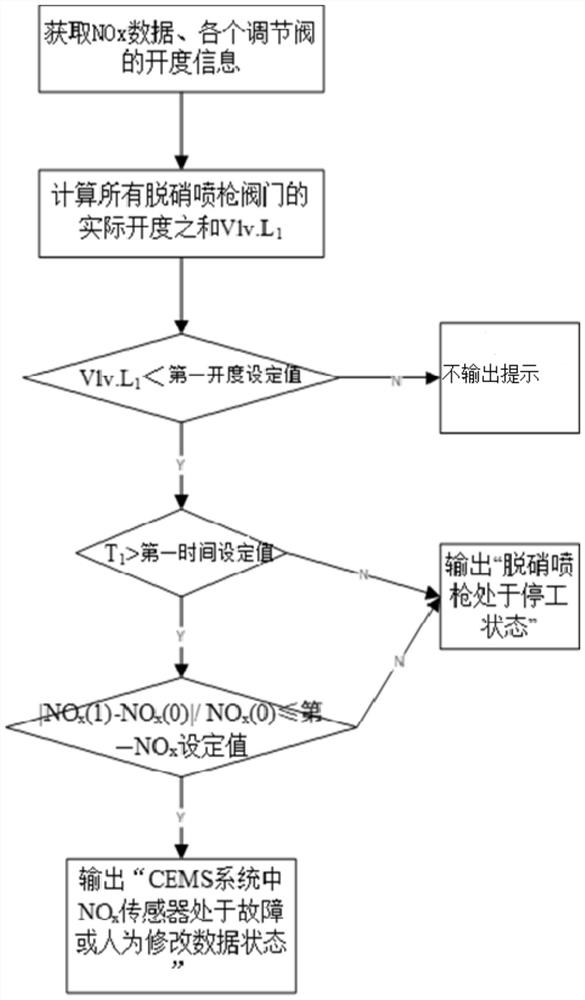

[0139] In this embodiment, the monitoring module of the denitration spray gun includes a regulating valve arranged on the pipeline of each denitration spray gun, and the flow rate of the denitration spray gun can be controlled by adjusting the opening of the regulating valve. The regulating valve sends its opening degree information to the central controller. In the monitoring module of the denitrification spray gun, the central controller also receives NO from the CEMS system x NO in the flue gas provided by the sensor x data, central controller opening degree information and NO x After the data is calculated, alarms and prompts are output according to the calculation results.

[0140] Specifically, in the denitrification spray gun monitoring module, the central controller performs the following operations after obtaining the opening information and time of each regulating valve:

[0141] 1), calculation

[0142] Among them, Vlv(x).L 1 is the actual opening of the regu...

Embodiment 2

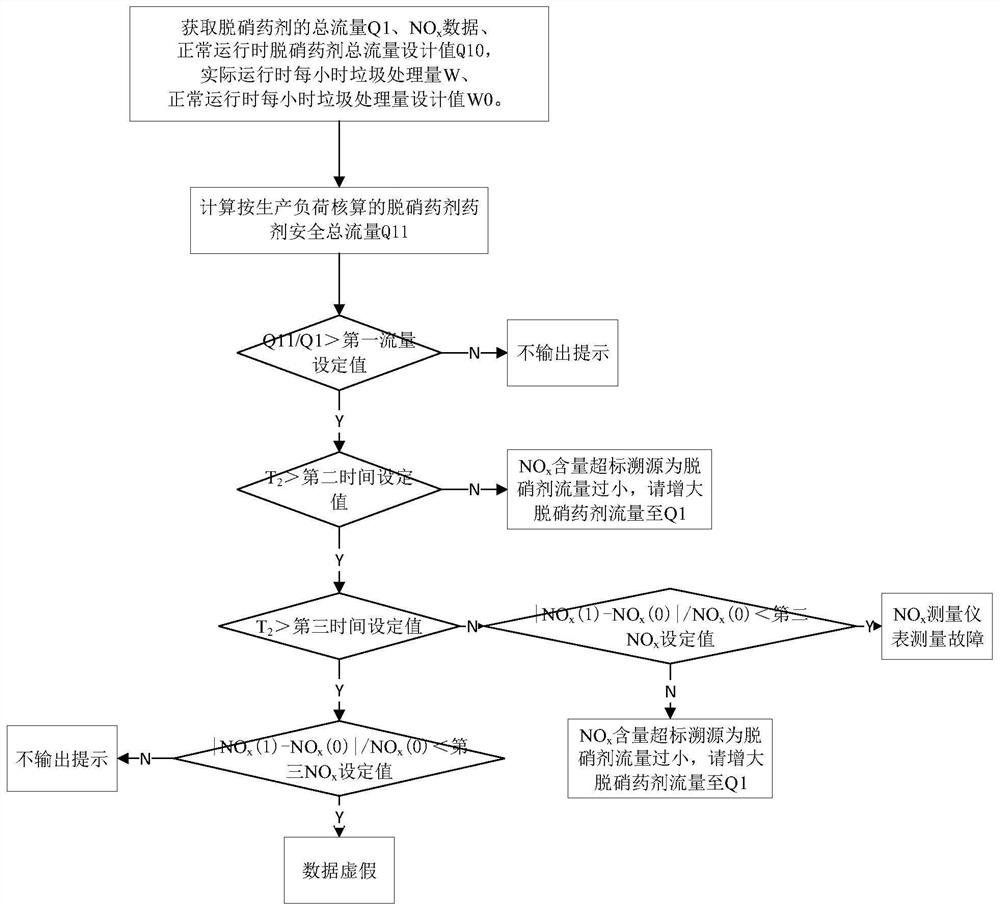

[0161] In this embodiment, the monitoring module of the denitrification spray gun includes a flow meter arranged on the pipeline of the denitrification spray gun, and the flow meter can feed back the total flow Q1 of the denitrification agent of the denitrification spray gun to the central controller. The central controller also accepts the NO from the CEMS system x NO in the flue gas provided by the sensor x data, the central controller passes through the total flow Q1 and NO x The data is calculated, so that we can know whether the current flow meets the denitrification requirements, and whether there is a fault or fraud in the CEMS system.

[0162] Specifically, in the monitoring module of the denitrification spray gun, the central controller performs the following calculation steps:

[0163] 1), calculate Q11=Q10*(W / W0),

[0164] Among them, Q11 is the safe total flow rate of denitrification agent calculated according to the production load, Q10 is the design value of t...

Embodiment 3

[0195] In this embodiment, the monitoring module of the acid removal reaction tower includes a regulating valve arranged on the lime water pipeline, and the regulating valve can adjust the opening degree to control the flow of lime water. The lime water pipeline regulating valve sends its opening information Vlv.L 2 sent to the central controller. In the monitoring module of the acid removal reaction tower, the central controller also receives NO from the CEMS system x NO in the flue gas provided by the sensor x data, SO 2 SO in the flue gas provided by the sensor 2 Data, the HCl data in the flue gas provided by the HCl sensor, the opening of the central controller Vlv.L 2 and NO x data, SO 2 After the data and HCl data are calculated, alarms and prompts are output according to the calculation results.

[0196] Specifically, in the acid removal reaction tower monitoring module, the central controller performs the following calculations:

[0197] 1), compare Vlv.L 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com