Rail car cable storage mechanism

A rail car and cable technology, applied in the field of rail car cable storage mechanism, can solve the problems of unsuitable long-distance routing, easy entanglement of cables, limited routing space, etc., to achieve fast and simple routing , the effect of not easy cable entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

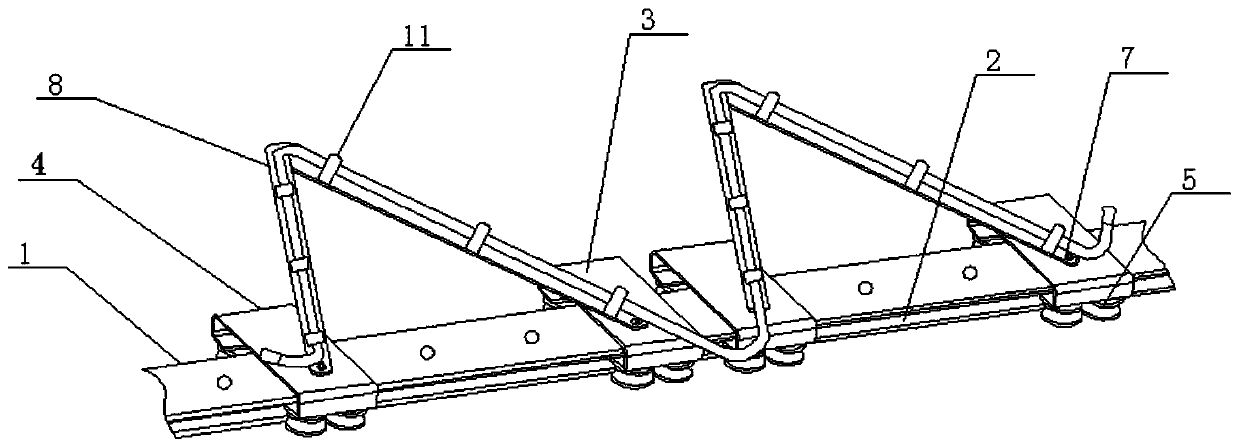

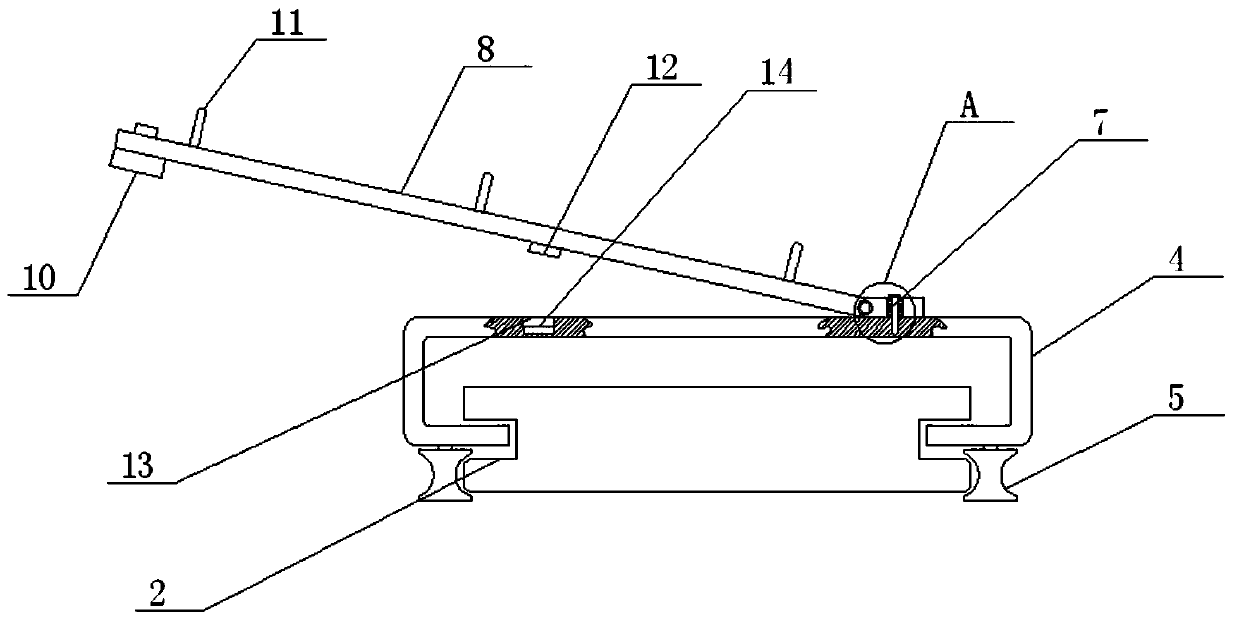

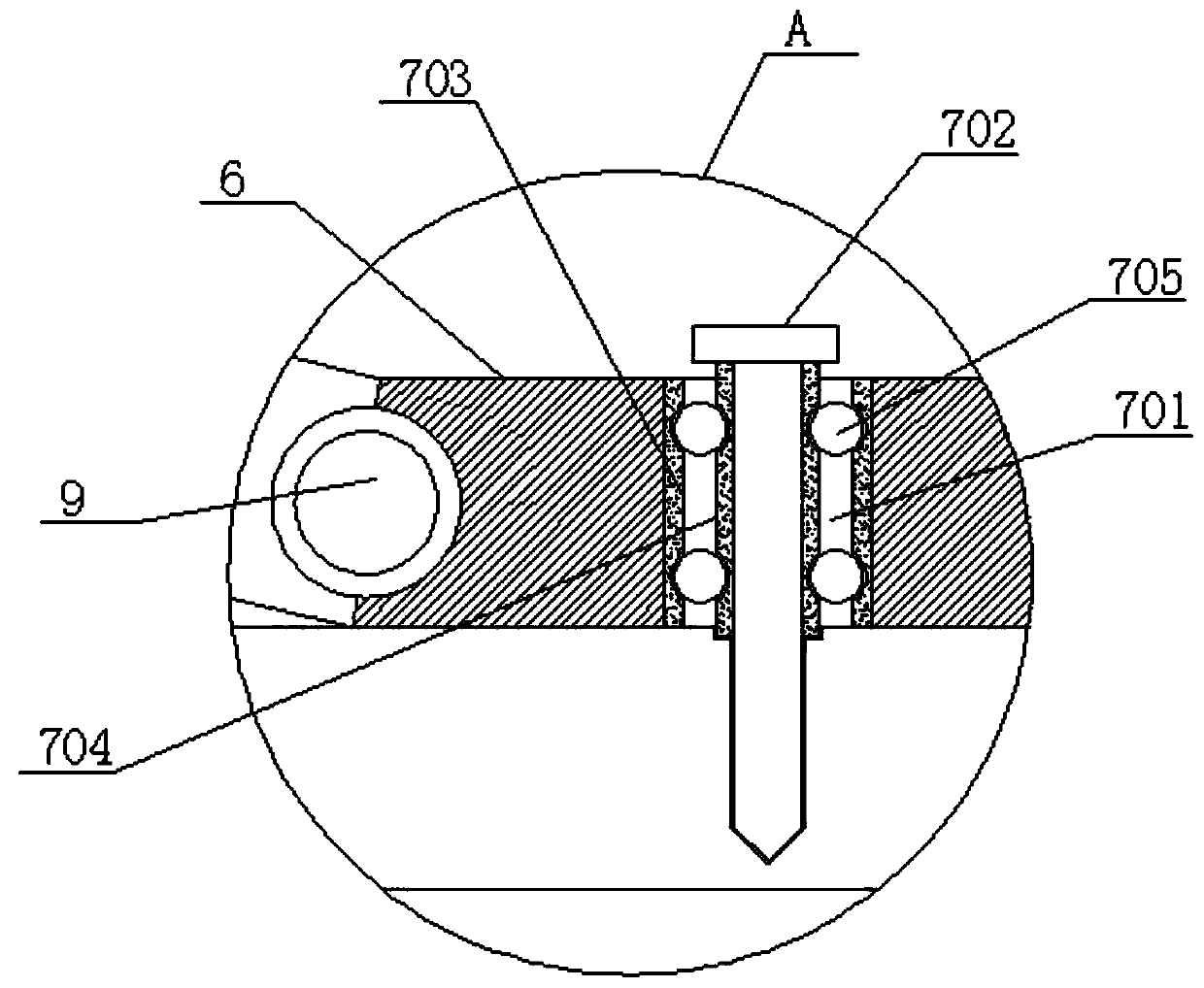

[0032] according to Figure 1-6 The shown cable storage mechanism for a rail car includes a rail frame 1, wherein the rail frame 1 is installed with a countersunk head screw and the installation part, and the width of the installed part is smaller than the width of the rail frame 1, and the rail frame 1 is Straight rails are set, track grooves 2 are provided on both sides of the track frame 1, and several groups of storage parts 3 are arranged on the surface of the track frame 1, wherein several groups of storage parts 3 form a complete storage mechanism, and the storage mechanism It is set at the opposite position to the installation part. By providing the storage sub-parts 3, it is beneficial to allow multiple storage sub-parts 3 to store the cables, thereby effectively making the wiring simple and less prone to cable entanglement during the mobile camera process, and It can be used in load situations such as formal installation, hoisting and limited space. The routing of th...

Embodiment 2

[0035] according to Figure 7 The shown cable storage mechanism for a rail car includes a rail frame 1, wherein the rail frame 1 is installed with a countersunk head screw and the installation part, and the width of the installed part is smaller than the width of the rail frame 1, and the rail frame 1 is Curved rails are arranged in an arc shape, track grooves 2 are provided on both sides of the track frame 1, and several groups of storage parts 3 are arranged on the surface of the track frame 1, wherein several groups of storage parts 3 form a complete storage mechanism, and the storage mechanism is located at the opposite position to the installation site. By providing the storage sub-piece 3, it is beneficial to allow multiple storage sub-pieces 3 to store the cables, thereby effectively making the wiring simple and convenient during the mobile camera process. Cable entanglement is not easy to occur, and it can be used in load situations such as formal installation, hoistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com