A non-synchronous reset method of a double-bracket brake booster

A technology of brake booster and reset method, which is applied in the direction of foot-operated starting devices, etc., can solve problems such as large force, and achieve the effect of fast braking response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

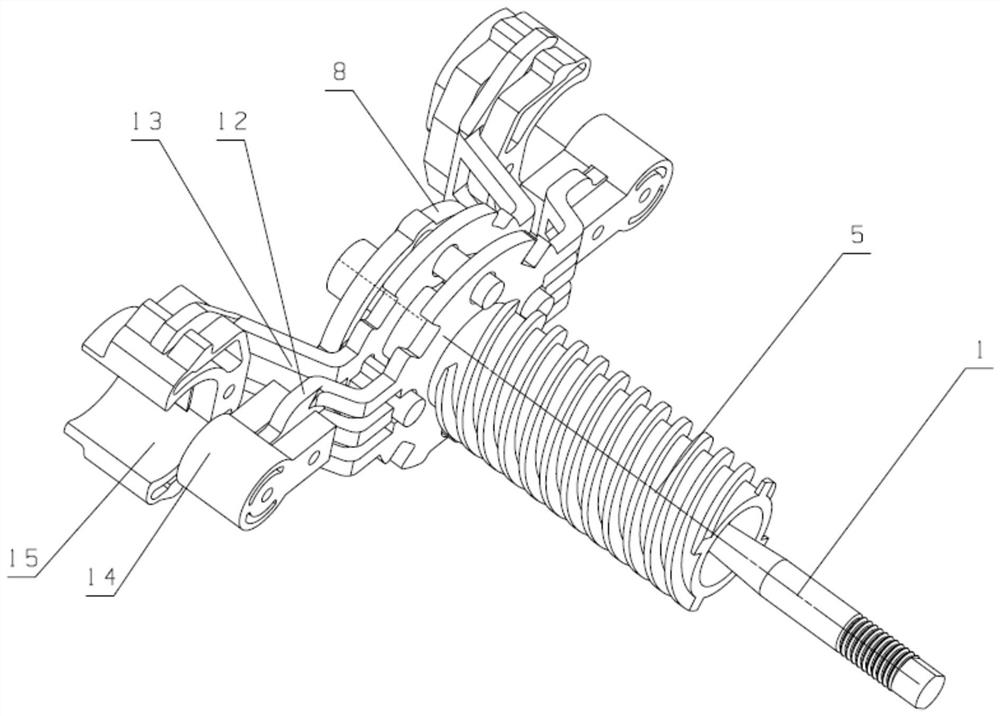

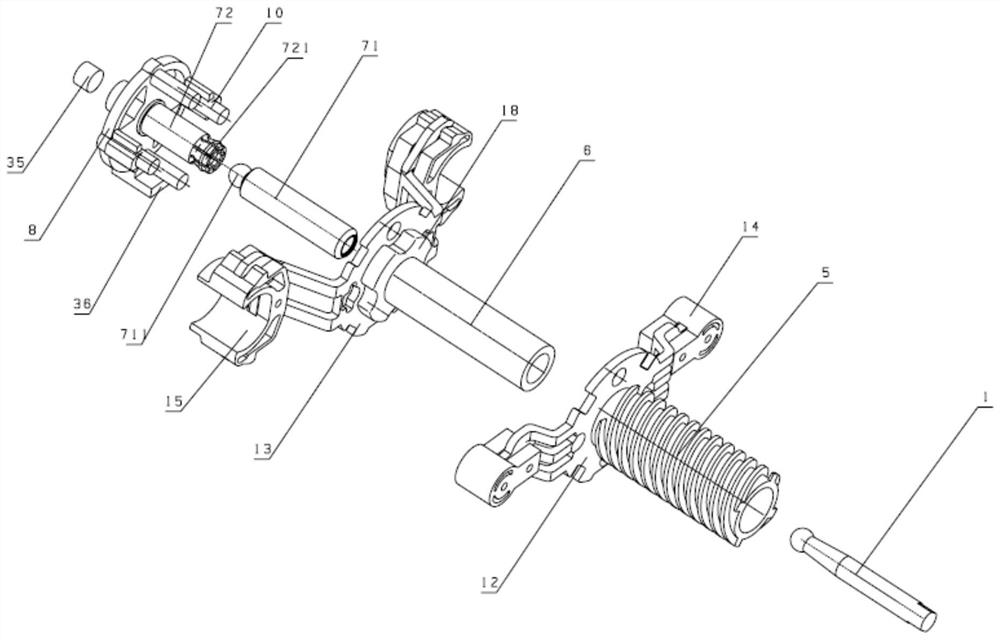

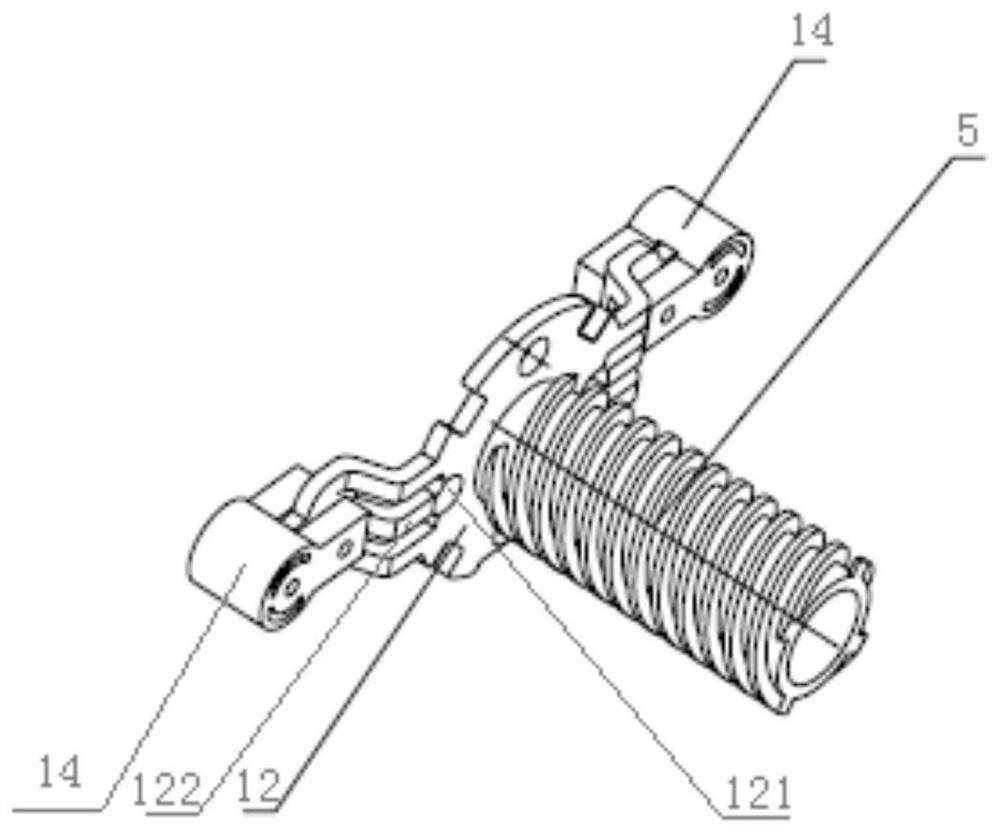

[0022] The present invention will be further described below with reference to the accompanying drawings.

[0023] The asynchronous reset method of the double-support brake booster provided by the present invention is to improve and design the single-support assembly unit in the traditional brake booster into a double-support assembly unit, which mainly includes a pedal force support and an electric power support. Then design corresponding reset units for the pedal force bracket and the electric power bracket, so that when the pedal force disappears, the second group of reset springs drive the electric power bracket to reset first, and the first group of reset springs drive the pedal force bracket to follow-up reset.

[0024] The first group of return springs can be the central springs arranged on the central axis of the brake booster, or the first peripheral springs arranged on the peripheral side of the central axis of the brake booster; the second group of return springs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com