Inclined valve bag packaging machine

A tilting valve and packaging machine technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of not being fixed to each other, stacking, etc., and achieve the effect of improving stability and reliability and improving flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

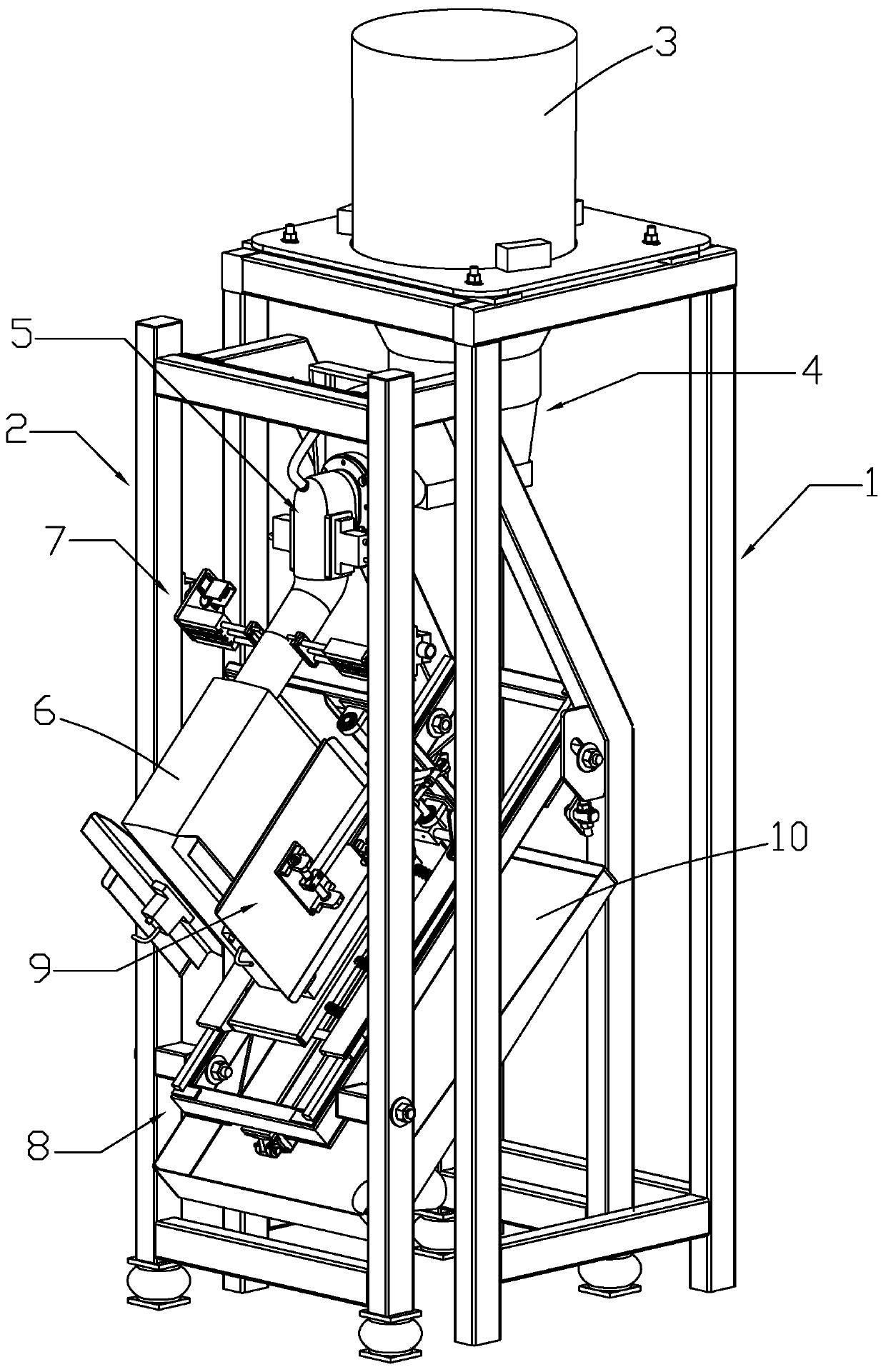

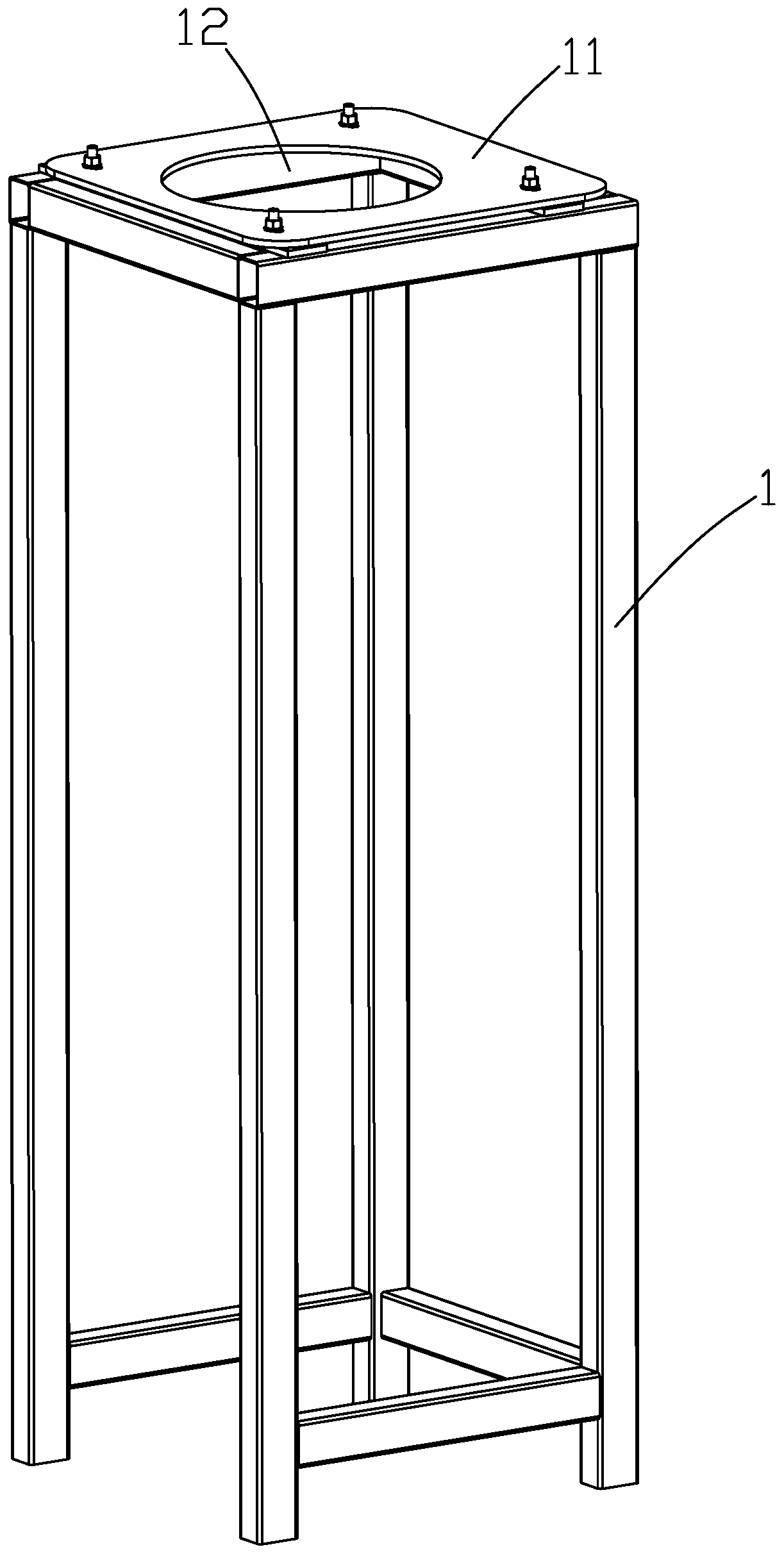

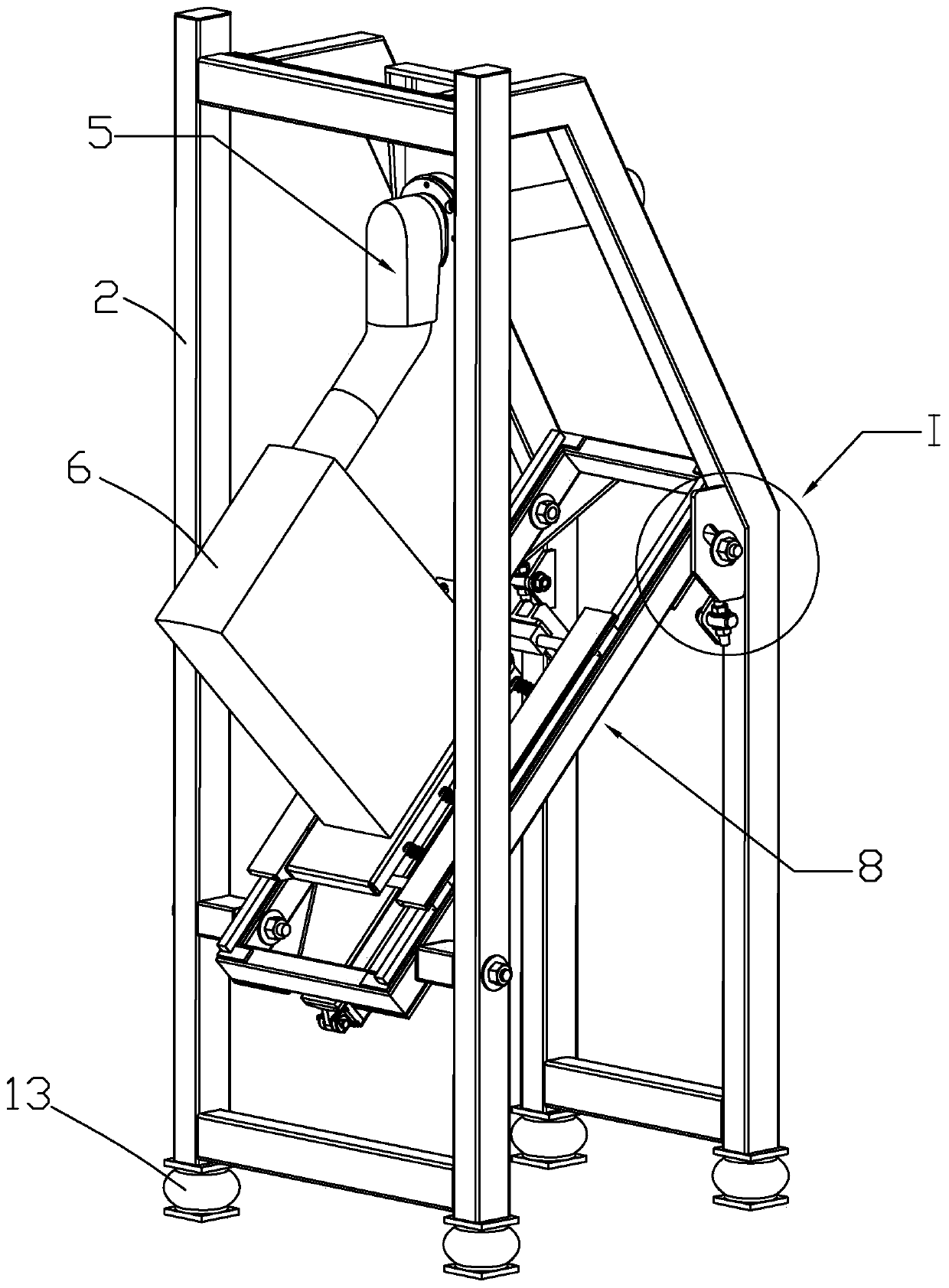

[0046] Such as Figure 1 to Figure 13 As shown, it is an inclined valve bag packaging machine of the present invention, which includes a filling machine body support 1 and a material bag platform support 2, and also includes an inclined bag holding mechanism, which is connected to the material bag platform support 2 and the material bag 6 The oblique filling of materials is realized through the tilting bag holding mechanism; the tilting material bag 6 is filled with materials through the tilting bag holding mechanism, which improves the filling rate, solves the problem of material accumulation and leakage at the mouth of the material bag 6, and ensures a safe working environment. Clean, reducing the influence of the filling vibration of the material bag 6 on the weight, the material bag platform support 2 is embedded in the filling machine body support 1, and the two do not touch each other and are not fixed to each other. After installing various parts, they can still be disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com