A pipe clamping device and method of use

A technology of pipes and clasps, which is applied in the direction of pipe connection layout, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of pipe pulling, affecting the sealing effect of joints, and water leakage, so as to save manpower and material resources and reduce water pipes. Excellent maintenance and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by specific examples.

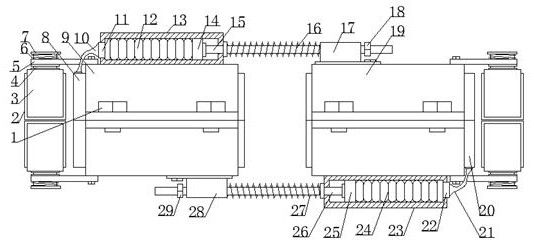

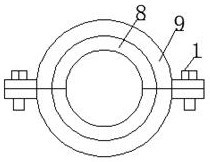

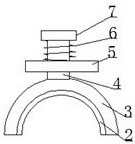

[0022] Such as Figure 1~Figure 3 As shown, a pipe clamping device includes a first snap ring 9 and a second snap ring 19, and fastening screws 1 are symmetrically installed between the first snap ring 9 and the second snap ring 19, and the first snap ring 9 and the second clasp 19 outer sides are all symmetrically fixedly equipped with a connecting plate 5, the connecting plate 5 is provided with a slide bar 4, the upper side of the slide bar 4 surface is provided with a first coil spring 6, and the outer end of the slide bar 4 is welded with a Baffle plate 7, push ring 3 is welded on the inner end of slide rod 4, anti-skid layer 2 is fixedly installed on the inner surface of push ring 3, first guide tube 13 is welded on the upper surface of first snap ring 9, and first guide tube 13 is sleeved inside There is a first telescopic airbag 12, the first airbag 11 is fixedly installed on the left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com