Double-component essence face cream

A two-component, essence technology, applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve the problem of too many bottles and cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0058] Add 20g of azobisisobutyronitrile into the Erlenmeyer flask containing 100g of ethanol, connect a spherical condenser to the Erlenmeyer flask, start the condensed water cycle at normal temperature, and stir the Erlenmeyer flask at 60°C with a magnetic stirrer until even Azobisisobutyronitrile was completely dissolved, the heat source was removed, the system temperature was lowered to 10° C., and azobisisobutyronitrile crystals were obtained by filtering with double-layer filter paper.

[0059] Repeat 2-3 times to obtain the desired pretreated azobisisobutyronitrile.

Synthetic example 2

[0061] Add 138g of pharmaceutical-grade salicylic acid and 142g of pharmaceutical-grade glycidyl methacrylate into the reactor, and continue the reaction at 50°C until the epoxy group is completely reacted to obtain intermediate A1;

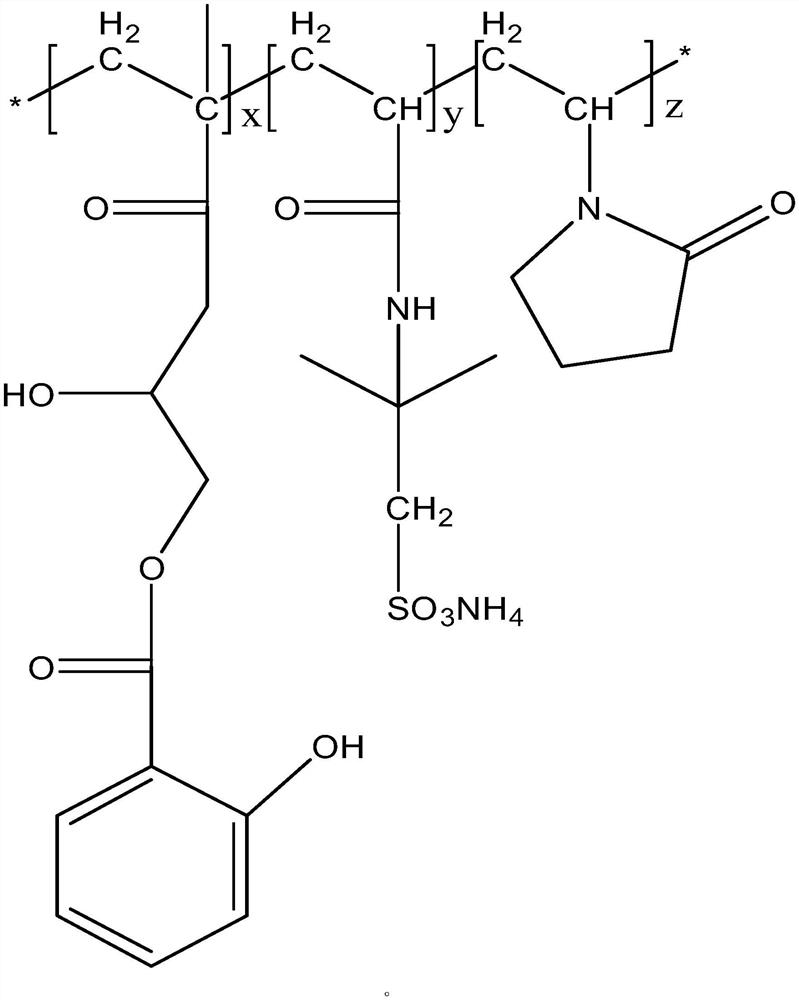

[0062] 20g of intermediate A1, 45g of pharmaceutical grade ammonium acryloyldimethyltaurate, 35g of pharmaceutical grade vinylpyrrolidone, and 0.3g of pretreated azobisisobutyronitrile were added to 100g of ethyl acetate, Stir well. Add the above liquid into the reactor dropwise, carry out free radical polymerization at 70°C, and keep warm at 70°C for 2 hours after the dropwise addition;

[0063] Use 50g of Merck 200 mesh silica gel to fill the chromatographic column, and the resulting polymer solution is subjected to column chromatography;

[0064] Slowly add the polymer solution that has passed through the silica gel column dropwise into the pharmaceutical grade ethanol solution, and granular precipitation appears with stirring;

[0065] The ...

Synthetic example 3

[0067] Add 149g of pharmaceutical-grade salicylic acid and 142g of pharmaceutical-grade glycidyl methacrylate into the reactor, and continue the reaction at 50°C until the epoxy group is completely reacted to obtain intermediate A2;

[0068] Add 15g of intermediate A2, 45g of pharmaceutical grade ammonium acryloyldimethyltaurate, 40g of pharmaceutical grade vinylpyrrolidone, and 0.5g of pretreated azobisisobutyronitrile into 100g of ethyl acetate, Stir well. Add the above liquid into the reactor dropwise, carry out free radical polymerization at 70°C, and keep warm at 70°C for 2 hours after the dropwise addition;

[0069] Use 50g of Merck 200 mesh silica gel to fill the chromatographic column, and the resulting polymer solution is subjected to column chromatography;

[0070] Slowly add the polymer solution that has passed through the silica gel column dropwise into the pharmaceutical grade ethanol solution, and granular precipitation appears with stirring;

[0071] The preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com