Device and method for air leakage self-inspection and object to be tested for air leakage detection

A technology for testing objects and air tightness, which can be used in measuring devices, using liquid/vacuum for liquid tightness measurement, and measuring the acceleration and deceleration rates of fluids, etc. Leakage, not being detected immediately, etc., to achieve the effect of reducing volume, preventing self-failure, and preventing self-error interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

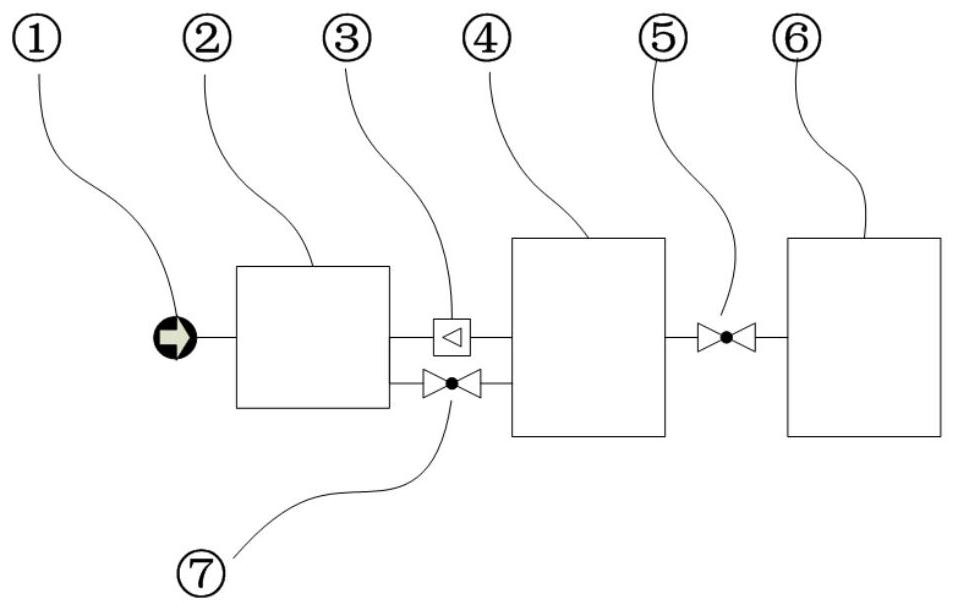

[0031] Such as Figure 1-3 As shown, an air tightness detection device with the function of correcting its own leakage and the influence of internal volume includes a fluid source 1, a control unit A2, a metering unit 3, a control unit B4, and a boundary valve 5 connected in sequence. The control A flow bypass valve 7 is connected between the unit A2 and the control unit B4; the control unit A2 controls the operation of the metering unit 3, the control unit B4, the boundary valve 5, and the flow bypass valve 7, and the control unit B4 includes one or more valves.

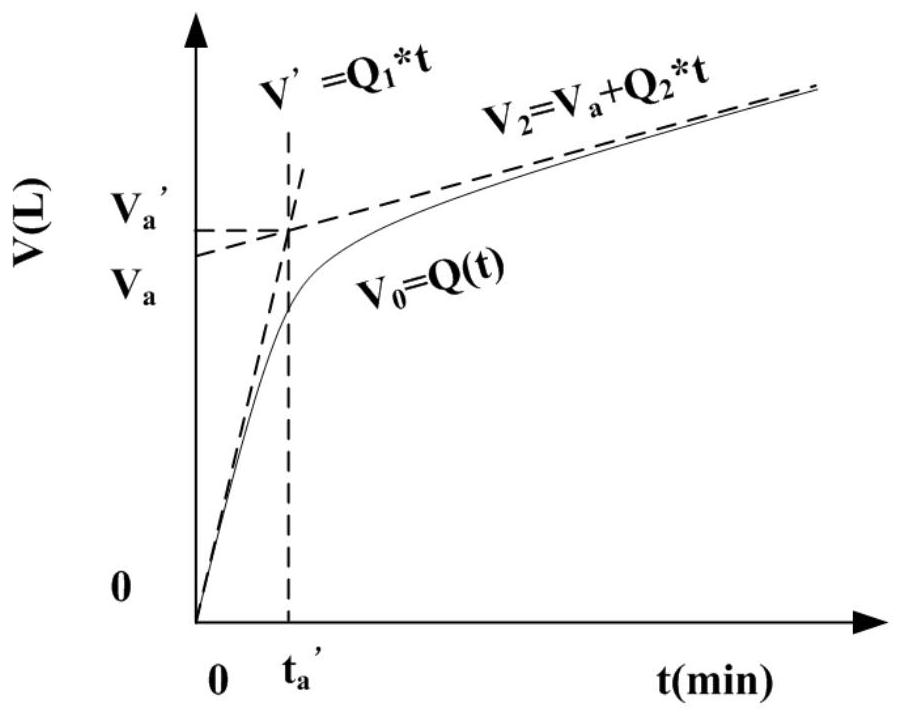

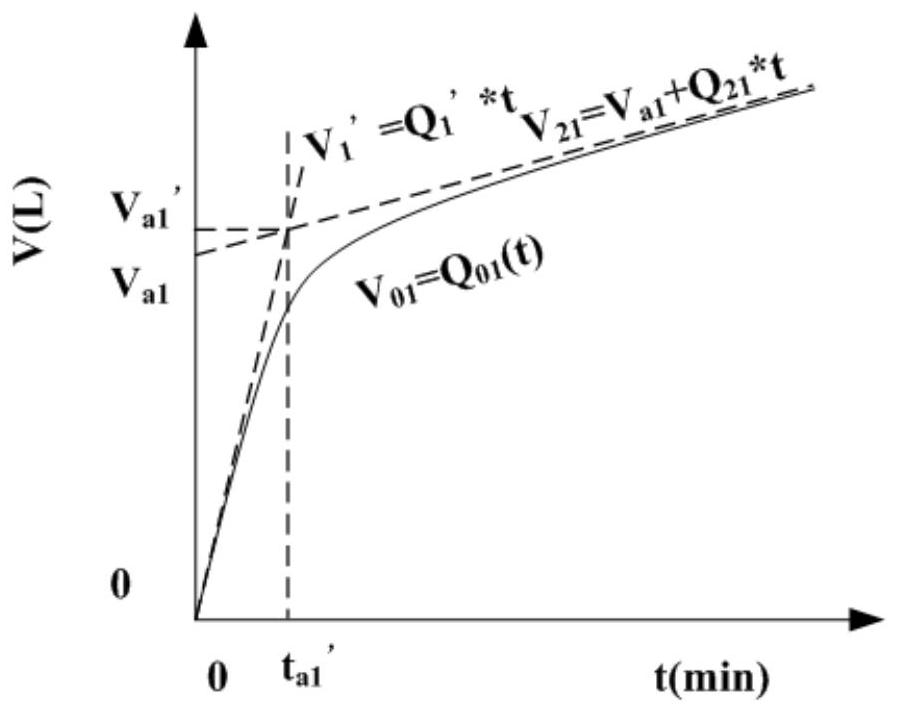

[0032] Take the inert gas medium as an example to make a technical description. According to the adsorption characteristics of different fluids in the cavity of the process container and the cavity of the target container, the fluid should be selected with relatively low inertness and adsorption characteristics. Under the actual operating pressure, the leakage and dead volume of the test system itself have a delay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com