Mixing control method for pre-plasticizing of plastic powder

A technology of mixing control and plastic powder, applied in the field of powder pre-plasticization, can solve the problems of no temperature rise control, affecting the performance of plastic products, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

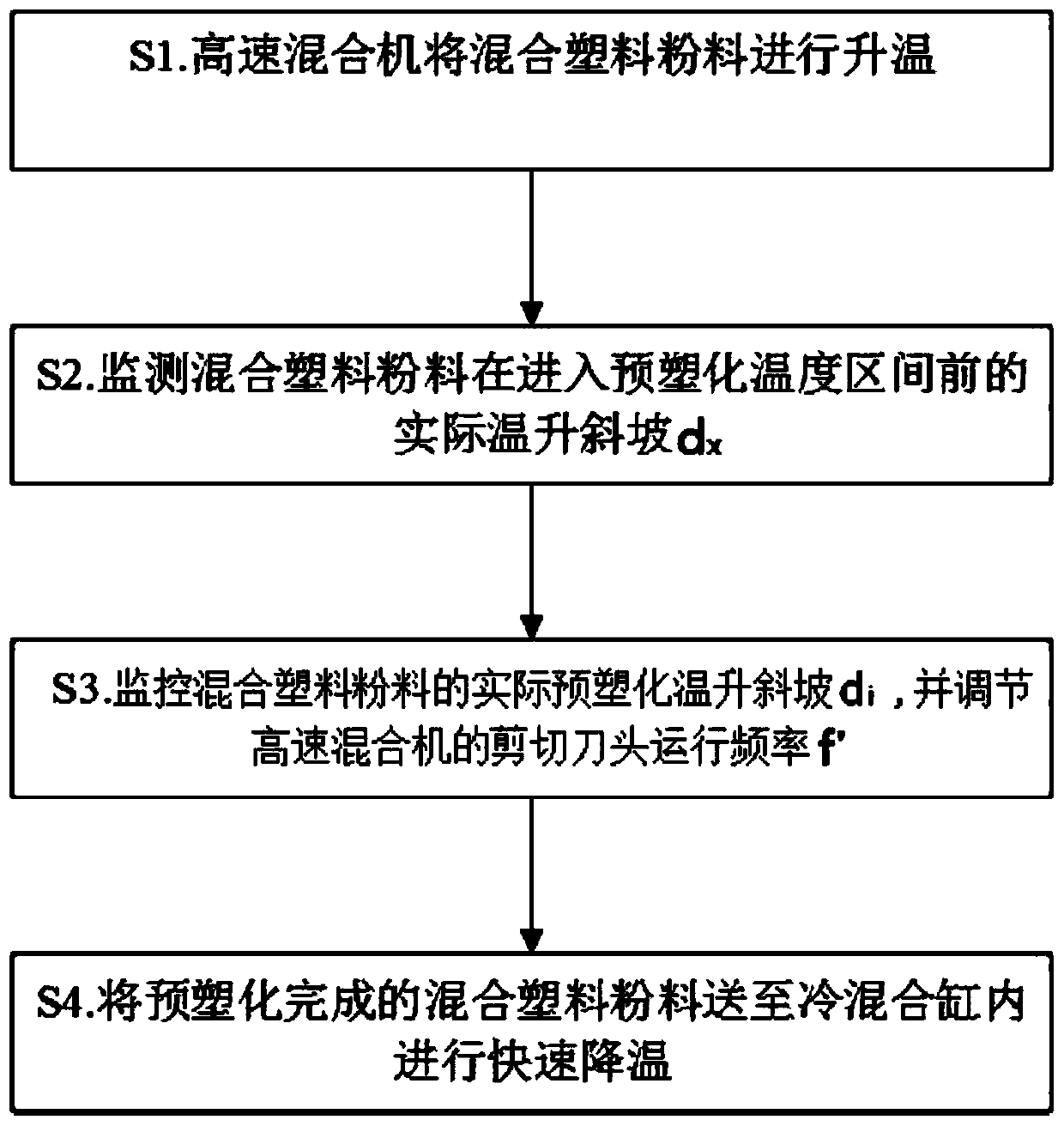

[0020] Such as Figure 1 to Figure 2 Shown is an embodiment of a mixing control method for plastic powder pre-plasticization in the present invention. A mixing control method for plastic powder pre-plasticization, comprising the following steps:

[0021] S1. The high-speed mixer heats up the mixed plastic powder;

[0022] S2. Monitor the actual temperature rise slope d of the mixed plastic powder before entering the pre-plasticizing temperature range x The difference with the temperature rise slope threshold d', if the difference does not meet the preset value, stop the pre-plasticization process, and if the difference meets the preset value, enter step S3;

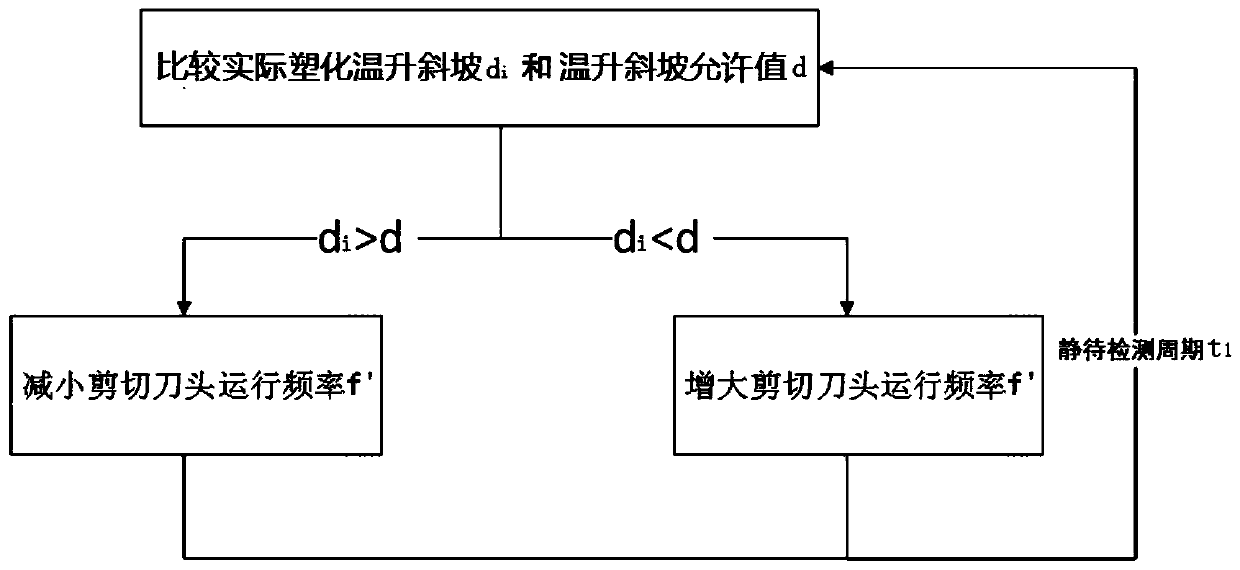

[0023] S3. The high-speed mixer continuously raises the temperature of the mixed plastic powder to the pre-plasticizing temperature range, and sets the duration of maintaining the pre-plasticizing temperature range, and monitors the actual pre-plasticizing temperature rise slope d of the mixed plastic powder i , adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com