Inner circle run-out testing fixture

A circular runout and inspection tool technology, applied in the inspection tool field, can solve problems such as large measurement errors, and achieve the effect of high measurement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

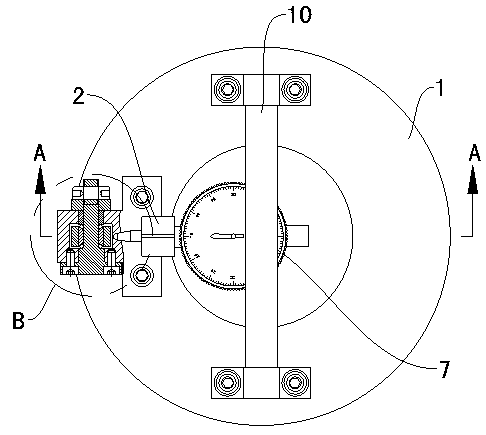

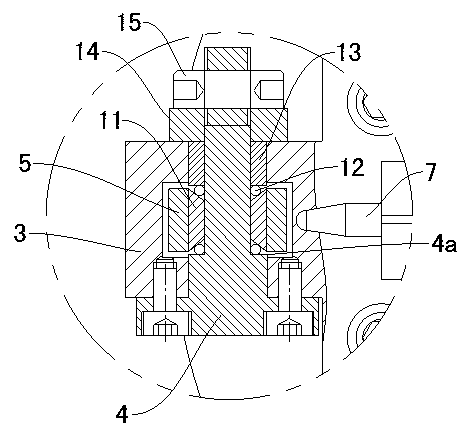

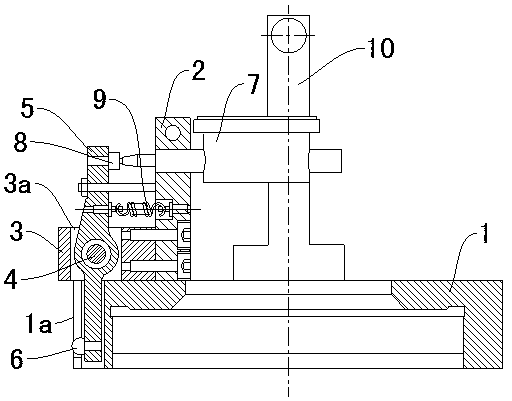

[0020] Such as Figure 1 to Figure 3 As shown, a checker for inner circle runout includes a rotating base 1, a lever 5, a gauge 7 and an anti-backlash mechanism. The rotating base 1 is a cylindrical structure, and the outer wall of the rotating base 1 is provided with a Groove 1a, a lever seat 3 is fixed on the upper end surface of the rotating seat 1, and a through hole 3a is opened in the said lever seat 3, and the middle part of the lever 5 is installed in the through hole 3a through the rotating shaft 4, and the lever The lower end of the lever 5 extends into the through groove 1a, the lower end of the lever 5 is fixed with a ball contact block 6, the upper end of the lever 5 is fixed with an abutment block 8, and one side of the lever seat 3 is fixed with a table seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com