A kind of mirror-faced aluminum strip material for automotive interior parts and preparation method thereof

A technology for automotive interior parts and mirror aluminum plates, applied in the field of aluminum alloy materials, can solve problems such as restricting applications, and achieve the effects of promoting dispersion and distribution, achieving stabilization, and meeting the needs of surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

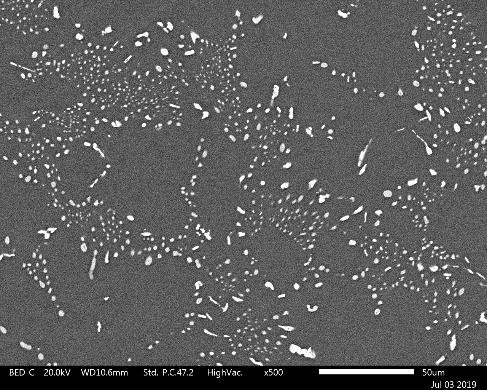

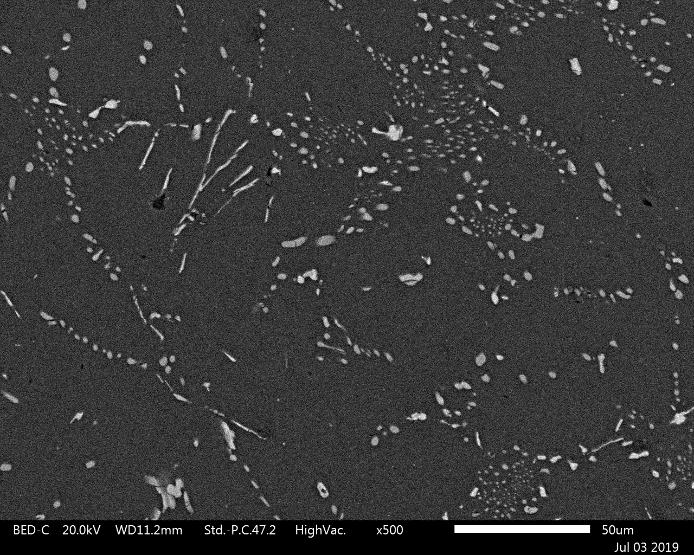

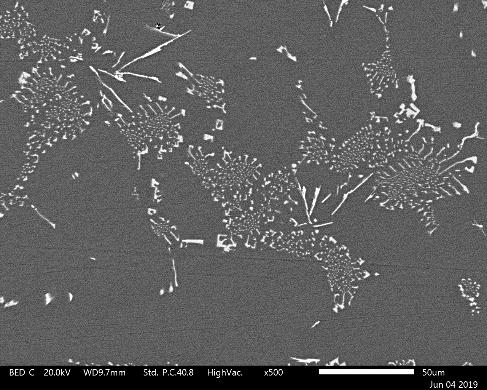

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of preparation method of mirror-faced aluminum sheet strip material for automotive interior parts, comprises the following steps:

[0037] (1) Melting and casting, using the method of semi-continuous casting, the casting temperature is 690±5°C, the stable production speed of the ingot is 50mm / min, the cooling water temperature is ≤30°C, and the thickness of the obtained ingot is 500~650mm;

[0038] (2) Heat treatment, using the integrated heat treatment of homogenization and heating. First, the obtained aluminum alloy ingot is slowly heated to 630°C at a heating rate of 30°C / h, and then heat-preserved for 16h; then cooled to 500°C and held for 10h. heat treatment;

[0039] (3) Hot rolling, the hot rolling process is divided into the initial stage of hot rolling, the stable stage of hot rolling and the end stage of hot rolling. %; when the thickness of the plate reaches about 280mm, it enters the stable stage of hot rolling. At this time, it is nece...

Embodiment 2

[0049] Example 2: (1) Melting and casting, using the method of semi-continuous casting, the casting temperature is 690±5°C, the stable production speed of the ingot is 50mm / min, the cooling water temperature is ≤30°C, and the thickness of the obtained ingot is 500~650mm ;

[0050] (2) Heat treatment, using the integrated heat treatment of homogenization and heating. First, the obtained aluminum alloy ingot is slowly heated to 610°C at a heating rate of 30°C / h, and then heat-preserved for 10h; then cooled to 510°C and held for 4h. heat treatment;

[0051] (3) Hot rolling, the hot rolling process is divided into the initial stage of hot rolling, the stable stage of hot rolling and the end stage of hot rolling. %; when the thickness of the plate reaches about 280mm, it enters the stable stage of hot rolling. At this time, it is necessary to increase the reduction rate to reach 10%~25%; when the thickness of the plate reaches about 50mm, it enters the end stage of hot rolling, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com