Patents

Literature

30results about How to "Meet the needs of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene composite material with high heat conductivity

InactiveCN107868337AHigh thermal conductivityLow thermal conductivityPolypropylene compositesGlass fiber

The invention belongs to the field of materials, and particularly relates to a polypropylene composite material with high heat conductivity. The polypropylene composite material is prepared from the following raw materials: 30 to 70 parts of polypropylene, 30 to 70 parts of a heat conduction filler, 10 to 30 parts of modified glass fiber, 5 to 10 parts of a flame retardant, 0.2 to 0.5 part of a light stabilizer, 0.1 to 0.2 part of a coupling agent and 0.1 to 0.2 part of an antioxidant. The modified glass fiber is obtained by performing surface modification on glass fiber with dopamine and thencompounding the modified glass fiber with aluminum nitride. According to the polypropylene composite material with the high heat conductivity, after the glass fiber is subjected to the surface modification with the dopamine, aluminum nitride particles are attached to the glass fiber, thereby improving the heat conductivity of the glass fiber; the modified glass fiber is added into the heat conduction polypropylene, so that the mechanical property of a heat conduction polypropylene product is improved, and a requirement for the heat conductivity is guaranteed.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Polypropylene-polyamide thermal conductive composite material

InactiveCN107857937AImprove thermal conductivityLow thermal conductivityHeat-exchange elementsGlass fiberAntioxidant

The invention belongs to the field of materials, and in particular relates to a polypropylene-polyamide thermal conductive composite material. The polypropylene-polyamide thermal conductive compositematerial is prepared from the following raw materials in parts by weight: 30-70 parts of polypropylene, 30-70 parts of polyamide, 50-100 parts of thermally conductive filler, 20-40 parts of modified glass fibers, 20-30 parts of a compatibilizer, 10-15 parts of a flame retardant, 0.5-1.0 part of a light stabilizer, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant, wherein the modified glass fibers are composite aluminum nitride obtained by carrying out surface modification on glass fibers with dopamine. The surfaces of the glass fibers are modified by using the dopamine, so that aluminum nitride particles are attached to the surfaces of the glass fibers, and the thermal conductivity of the glass fibers is further improved; furthermore, the modified glass fibers are addedinto the polypropylene-polyamide composite material, so that the thermal conductivity of composite material products is ensured while the mechanical properties of the composite material products are enhanced.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

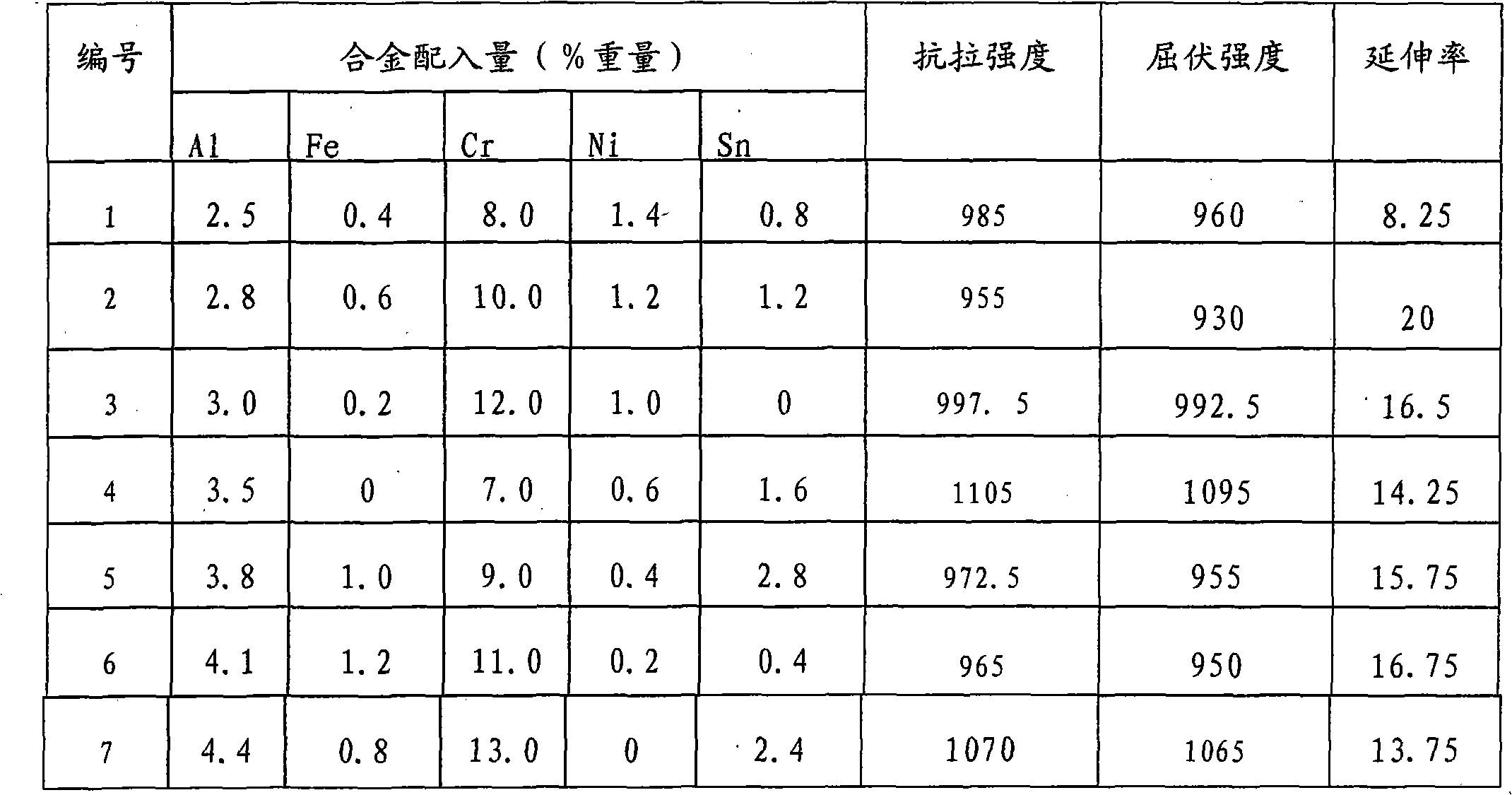

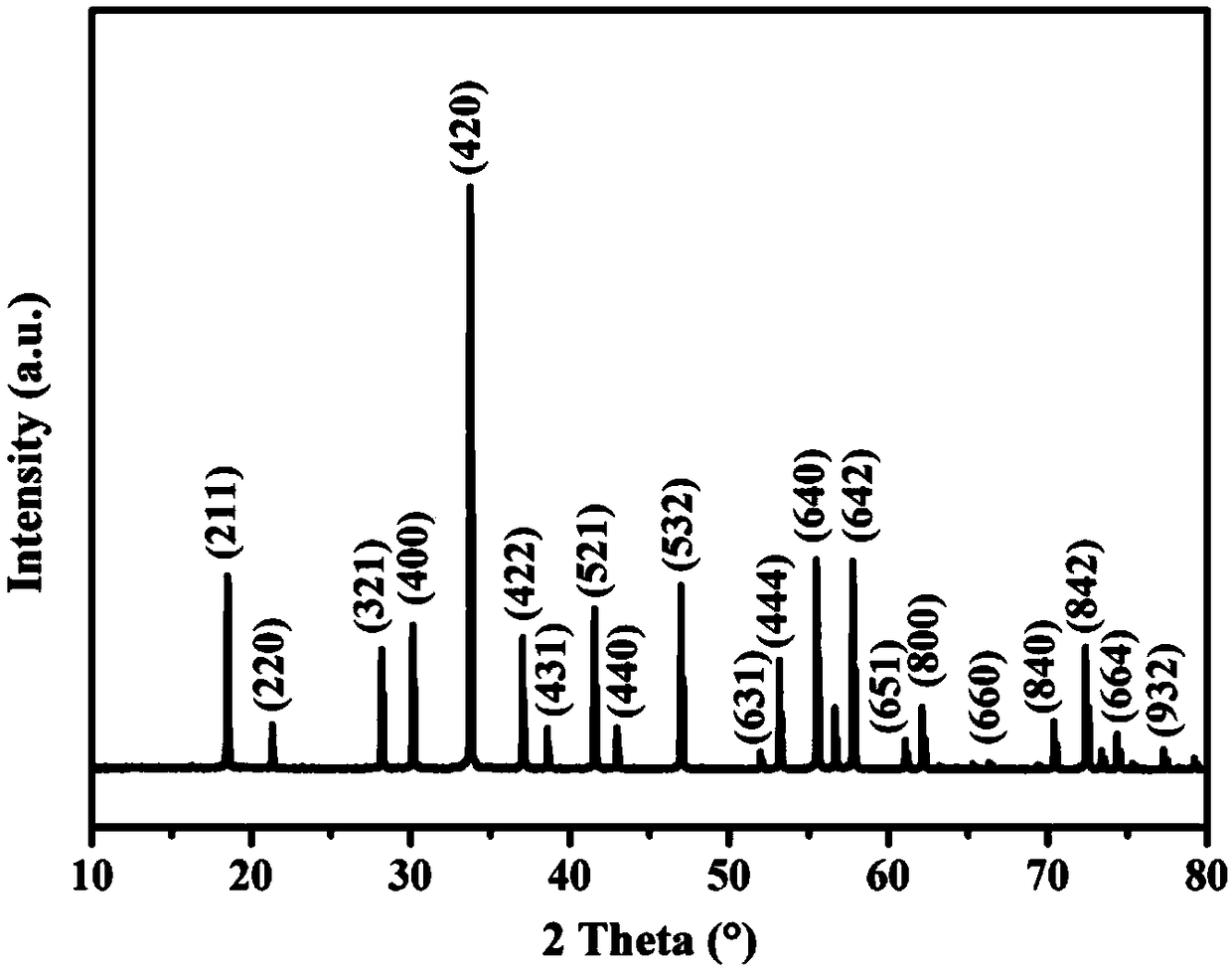

Low-cost beta titanium alloy

The invention discloses a low-cost beta titanium alloy composed of components of, by weight: 1.5-4.5% of aluminum, 7-14% of chromium, 0-1.5% of iron, 0-1.5% of nickel, 0-3% of tin, and balance of titanium and inevitable impurities. Essential elements of the titanium alloy provided by the invention do not include noble metals such as zirconium, molybdenum, and vanadium, such that the manufacturing cost of the beta titanium alloy is reduced. Also, the mechanical properties of the beta titanium alloy can satisfy titanium alloy mechanical property requirements of certain industries. Therefore, the market prospect of the low-cost beta titanium alloy is good.

Owner:北京正安广泰新材料科技有限公司

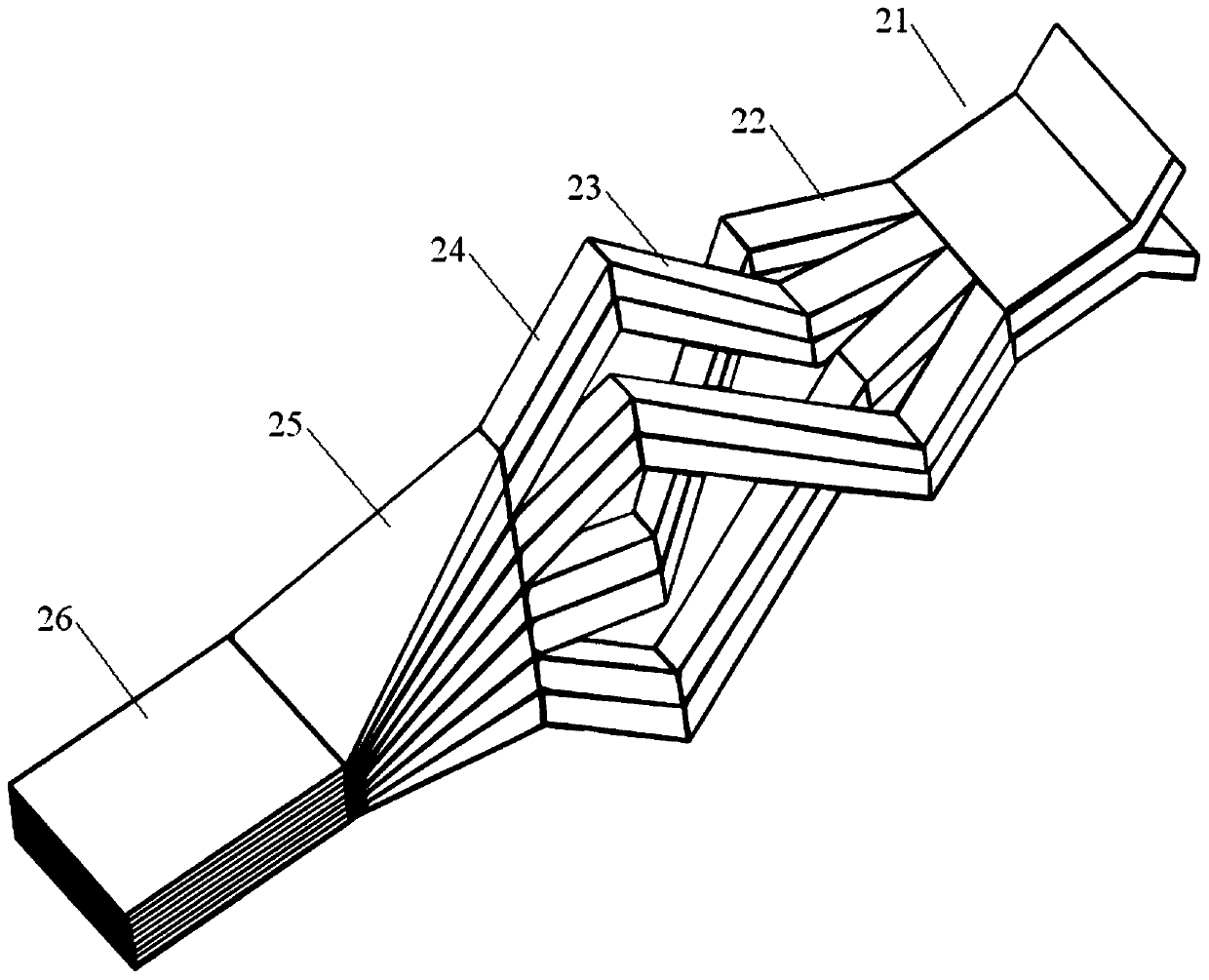

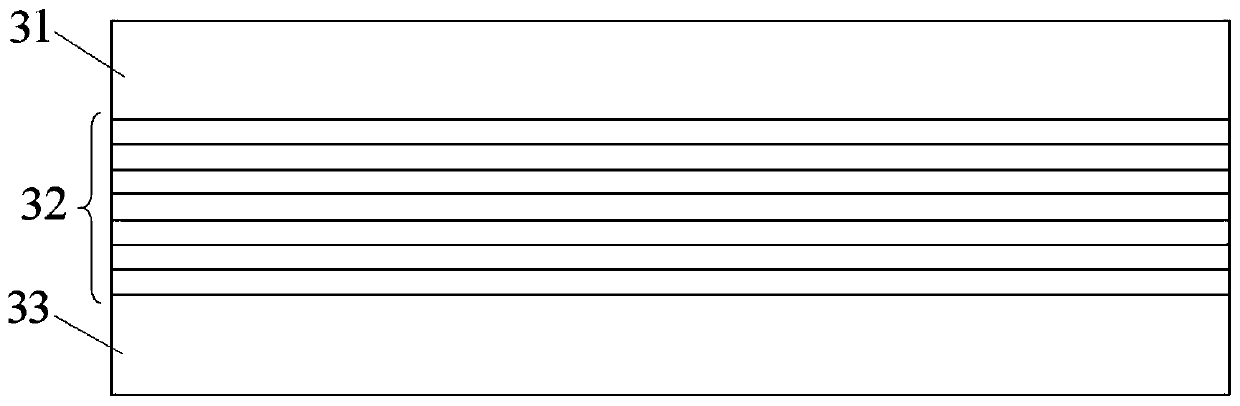

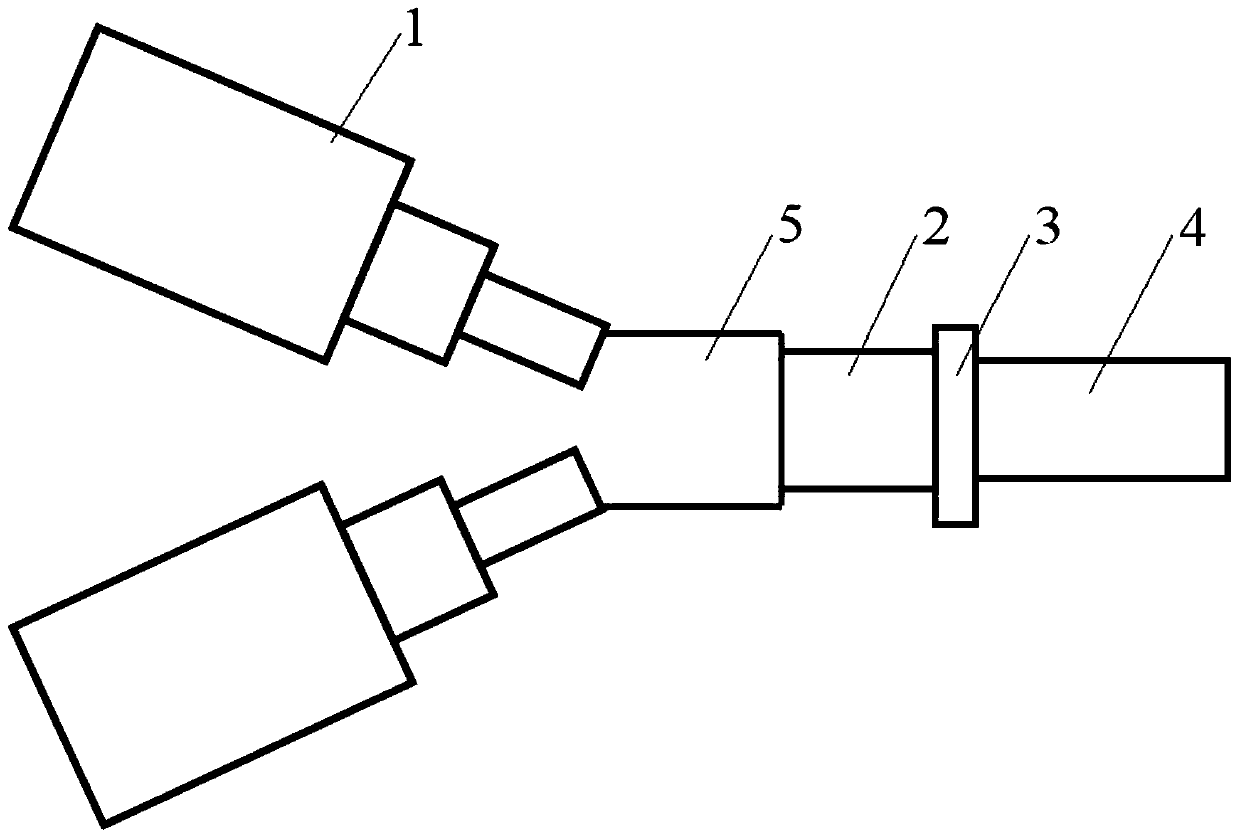

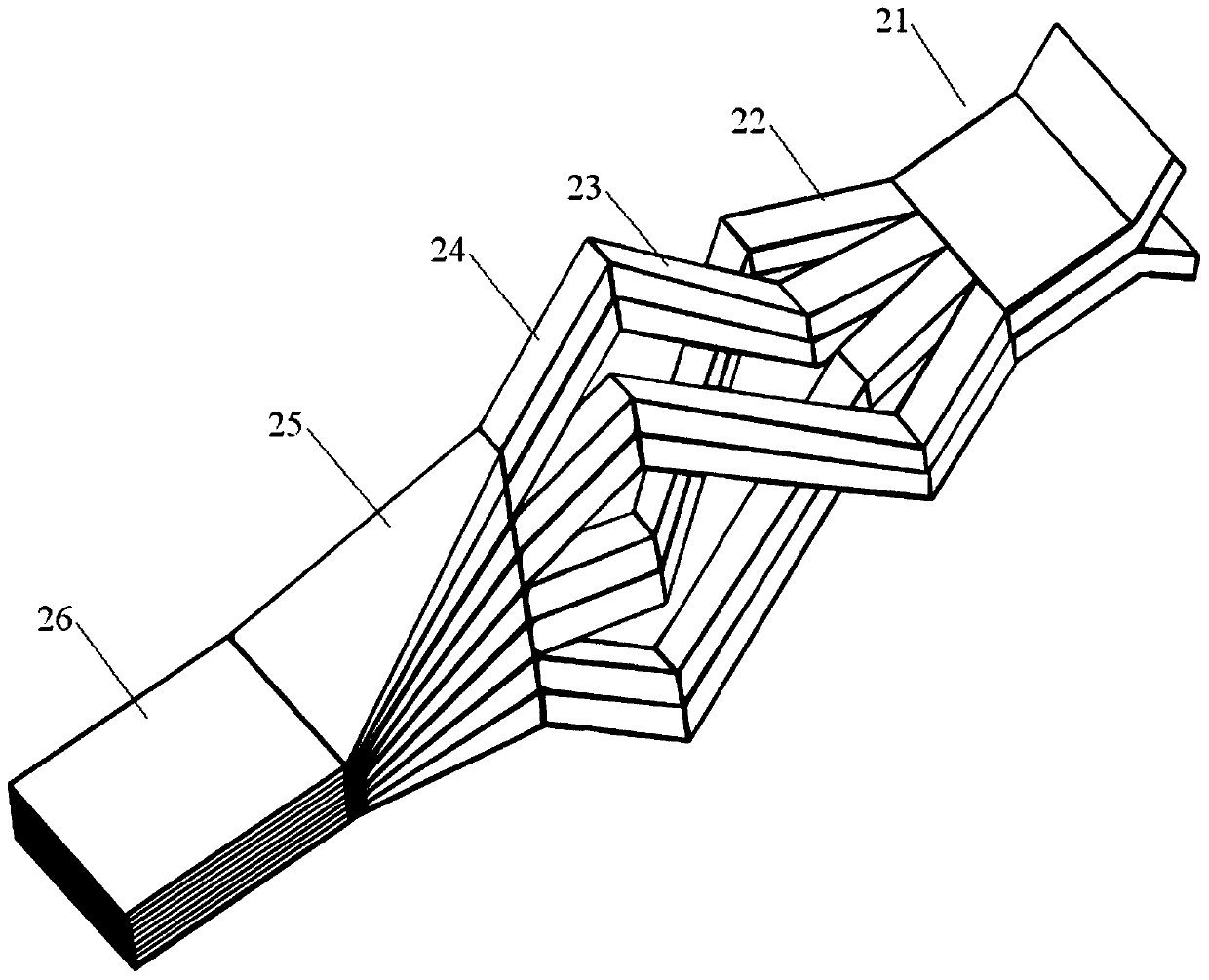

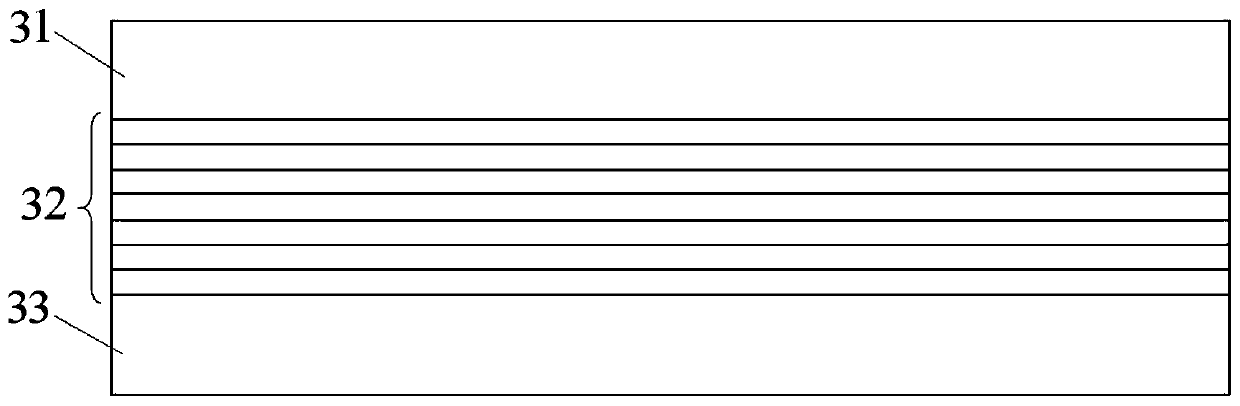

Multilayer composite polypropylene microporous membrane, preparation method thereof and application

InactiveCN109802079ASolve the problem of more through holesMeet the needs of mechanical propertiesCell component detailsMicro nanoSurface layer

The present invention discloses a multilayer composite polypropylene microporous membrane, a preparation method thereof and application. The multilayer composite polypropylene microporous membrane ofthe present invention is composed of an upper surface layer, a middle layer and a lower surface layer; and the middle layer is of a multilayer structure formed by polypropylene layers through a micro-nano lamination technique. According to the multilayer composite polypropylene microporous membrane, the middle layer of the multilayer structure formed through the micro-nano lamination technique isadopted, and therefore, on the one hand, the multi-layer structure has better safety, and on the other hand, with the middle layer formed by the micro-nano lamination technique adopted, the tensile strength, puncture strength and other mechanical properties of the battery diaphragm can be improved, and the battery diaphragm can be thinner, and therefore, the requirements of the thin and high-safety lithium battery diaphragm for mechanical properties and safety can be satisfied.

Owner:武汉中兴创新材料技术有限公司

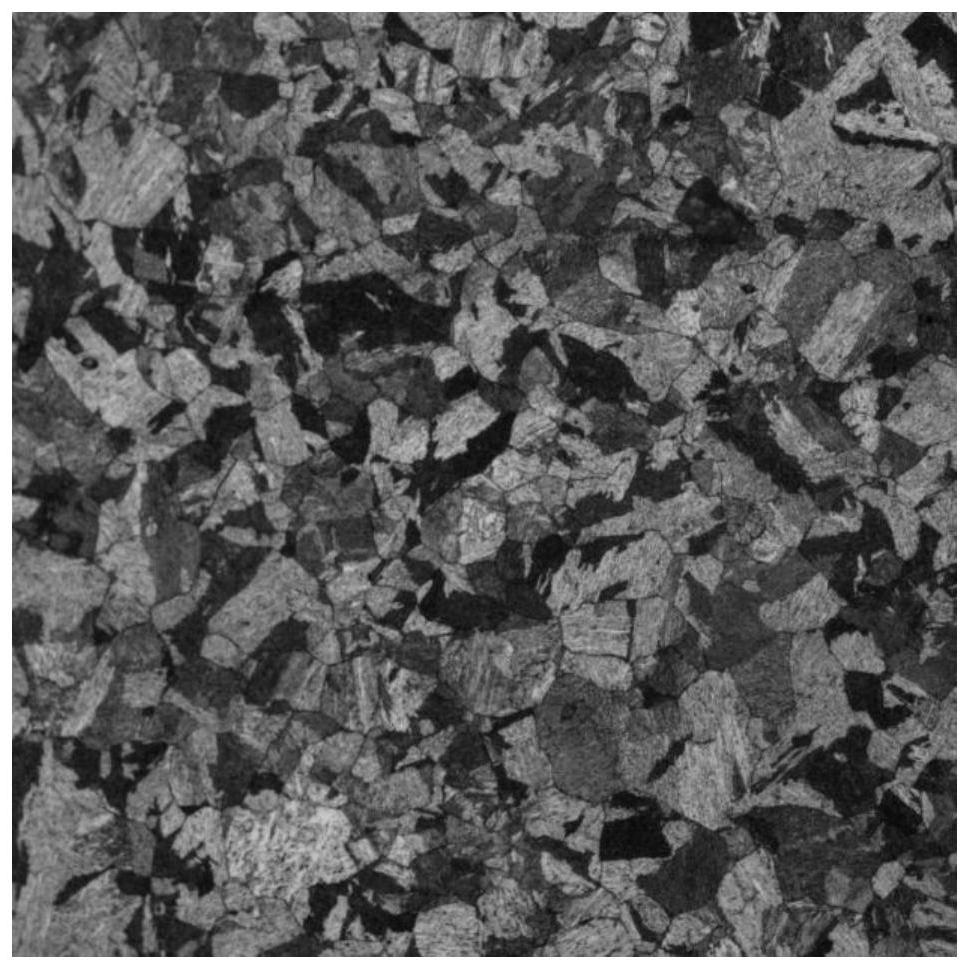

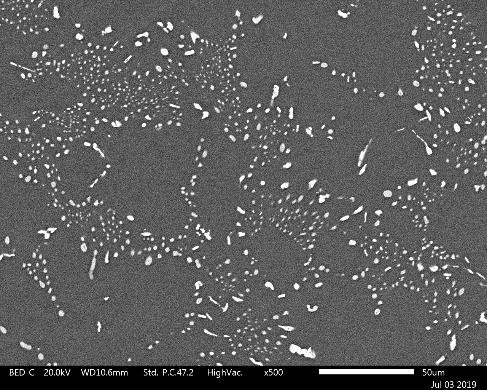

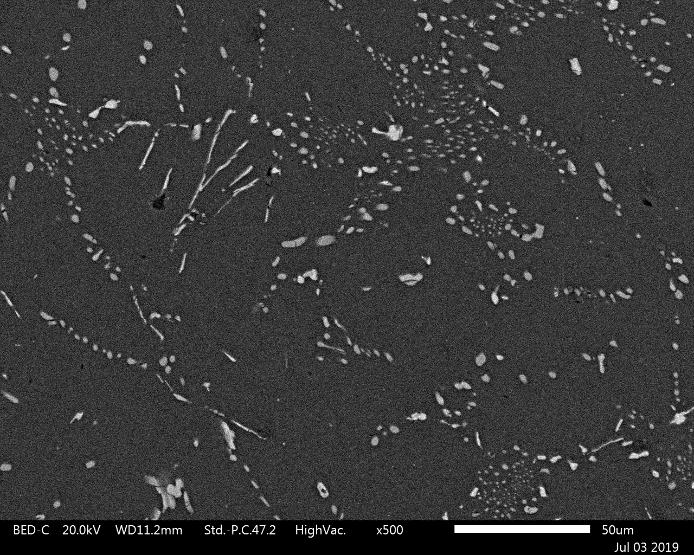

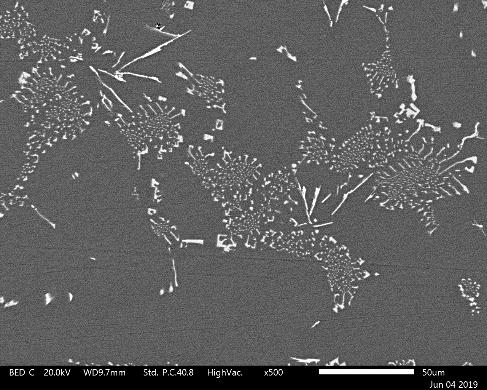

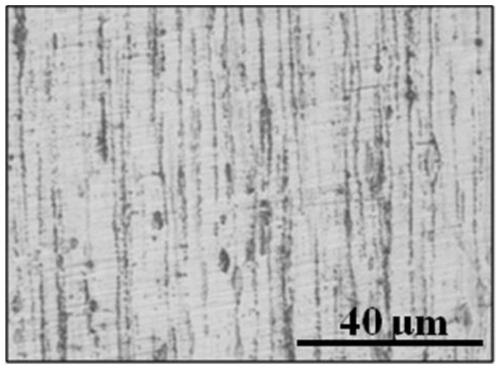

Mirror aluminum plate strip for automobile interior parts and preparation method of mirror aluminum plate strip

The invention provides a mirror aluminum plate strip for automobile interior parts and a preparation method of the mirror aluminum plate strip. The aluminum strip preparation method comprises the following steps of melting casting, homogenization and heating integrated heat treatment, hot rolling, cold rolling, mirror rolling and finished product annealing. An aluminum strip metal structure is small in grain size, random in texture distribution and uniform in second phase distribution. The aluminum strip is free of surface shading defects and has a mirror effect, the roughness is lower than orequal to 0.02 microns, the glossiness is higher than or equal to 750 GU, the tensile strength is 100 to 130 MPa, the yield strength is higher than or equal to 70 MPa, and the elongation is higher than or equal to 30%. All performance indexes of the aluminum strip meet the requirements for the use of the automobile interior parts.

Owner:中铝河南洛阳铝加工有限公司 +1

Novel heat-conducting nylon composite material and preparation method thereof

InactiveCN107760019AHigh thermal conductivityLow thermal conductivityHeat-exchange elementsGlass fiberHeat conducting

The invention belongs to the field of materials and in particular relates to a novel heat-conducting nylon composite material and a preparation method thereof. The novel heat-conducting nylon composite material is prepared from the following raw materials in parts by weight: 30 to 70 parts of nylon-6, 30 to 70 parts of heat-conducting filling, 10 to 30 parts of modified glass fibers, 5 to 10 partsof a flame retardant, 0.1 to 0.2 part of a coupling agent and 0.1 to 0.2 part of an antioxidant, wherein the modified glass fibers are obtained by carrying out dopamine surface modification on glassfibers and compounding aluminum nitride, and can be obtained by a blending method in a preparation process. According to the novel heat-conducting nylon composite material provided by the invention, the surfaces of the glass fibers are modified by adopting dopamine, so that aluminum nitride micro-particles are attached and the heat conductivity of the glass fibers is improved; and the modified glass fibers are added into the heat-conducting nylon, so that the mechanical properties of a heat-conducting nylon product are enhanced and the requirements on heat conductivity are ensured.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

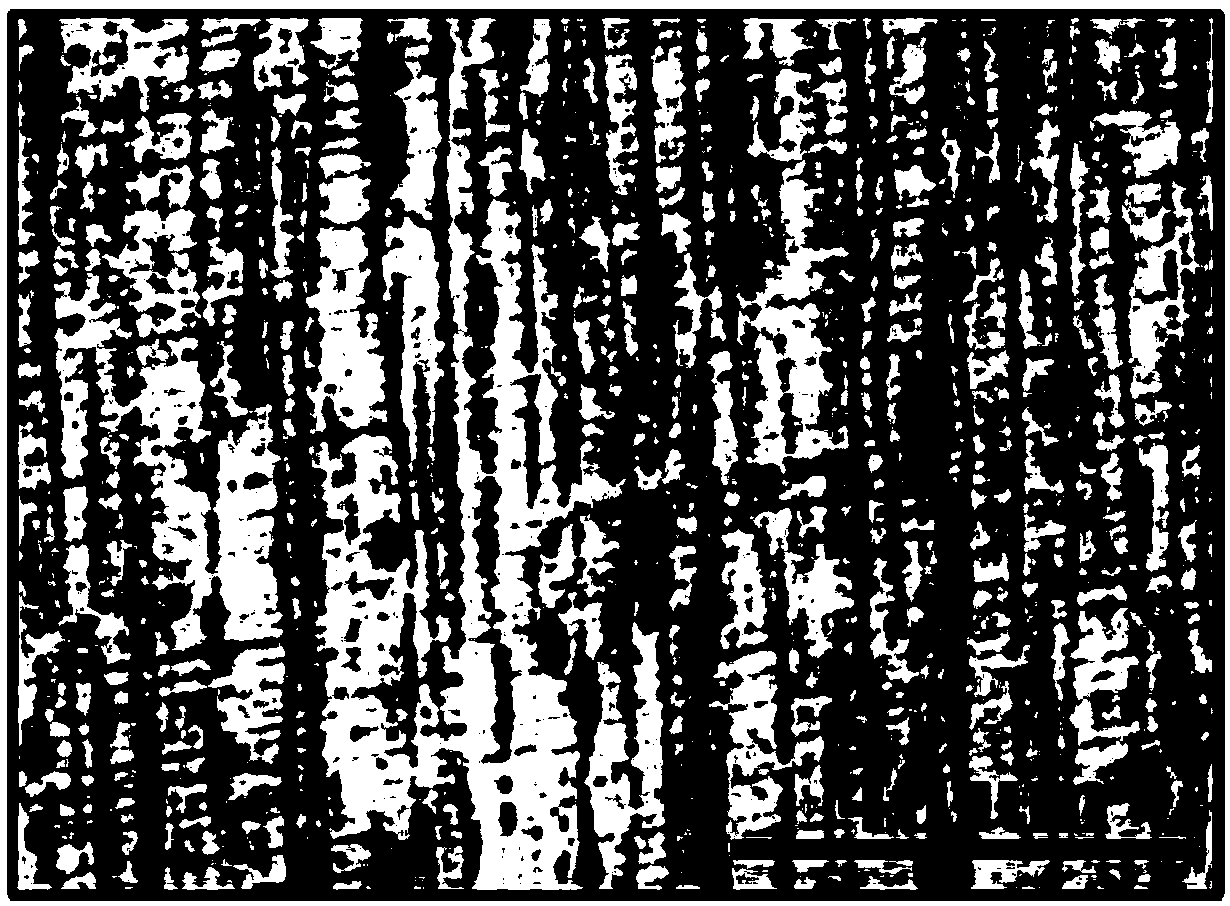

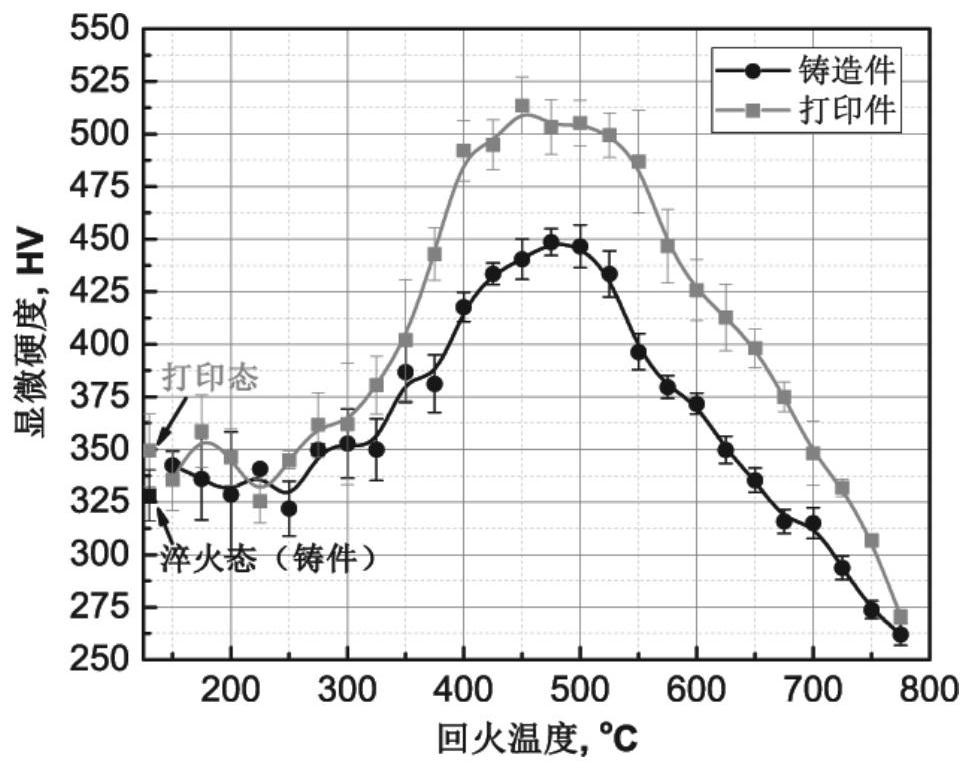

High-heat-conductivity and high-strength Co-Fe-Ni alloy for mold and additive manufacturing method thereof

ActiveCN112301255AMake up for the disadvantage of high costMaintain steel mechanical propertiesAdditive manufacturing apparatusTransportation and packagingEconomic benefitsAlloy

The invention relates to a high-heat-conductivity and high-strength Co-Fe-Ni alloy for a mold and an additive manufacturing method thereof. The high-heat-conductivity and high-strength Co-Fe-Ni alloycomprises the following chemical components in percentage by weight: 0-0.01% of C, 12-18% of Ni, 38-42% of Fe, 0-1.2% of Cr, 0-0.05% of X, less than 0.015% of P, less than 0.010% of S and the balanceCo and inevitable impurities, wherein X is equal to Sc, and / or Y, and / or Nd, and / or Pd. Compared with the prior art, the high-heat-conductivity and high-strength Co-Fe-Ni alloy has the advantages thata Co-based medium-entropy alloy is applied to the mold, different toughness combinations are regulated and controlled by utilizing additive manufacturing and subsequent heat treatment, the heat conductivity and the service reliability of the alloy are improved on the premise that the cost is not greatly increased and the same mechanical property of existing mold steel is kept, and the high-heat-conductivity and high-strength Co-Fe-Ni alloy can replace part of the existing mold steel and has considerable economic benefits.

Owner:SHANGHAI ESU LASER TECH CO LTD

High-strength heat-resistant magnesium alloy containing Ag and preparation method thereof

ActiveCN108624793AImprove mechanical properties at room temperatureHigh tensile strengthRare-earth elementHeat resistance

The invention provides high-strength heat-resistant magnesium alloy containing Ag. The high-strength heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.5-6.5percent of Y, 1.5-4.0 percent of Nd, 1.5-4.0 percent of Gd, 0.1-1.5 percent of Ag, 0.15-1.5 percent of Zr and the balance of Mg, wherein the total amount of the rare earth elements does not exceed 10percent by weight. The high-strength heat-resistant magnesium alloy comprises the following components: Mg-Y-Nd-Gd-Ag-Zr; a precipitate containing a rare earth inter-metallic compound is strengthenedas a main strengthening mechanism; a RE-Ag fine high temperature stable phase and an Mg-RE-Ag eutectic are formed through adding the Ag as a non-rare earth element; the newly-formed phase has the characteristics of fine dispersion and high temperature stability; the heat treatment age hardening effect and the heat resistance of the high-strength heat-resistant magnesium alloy are significantly improved. The invention further provides a preparation method of the high-strength heat-resistant magnesium alloy containing the Ag.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

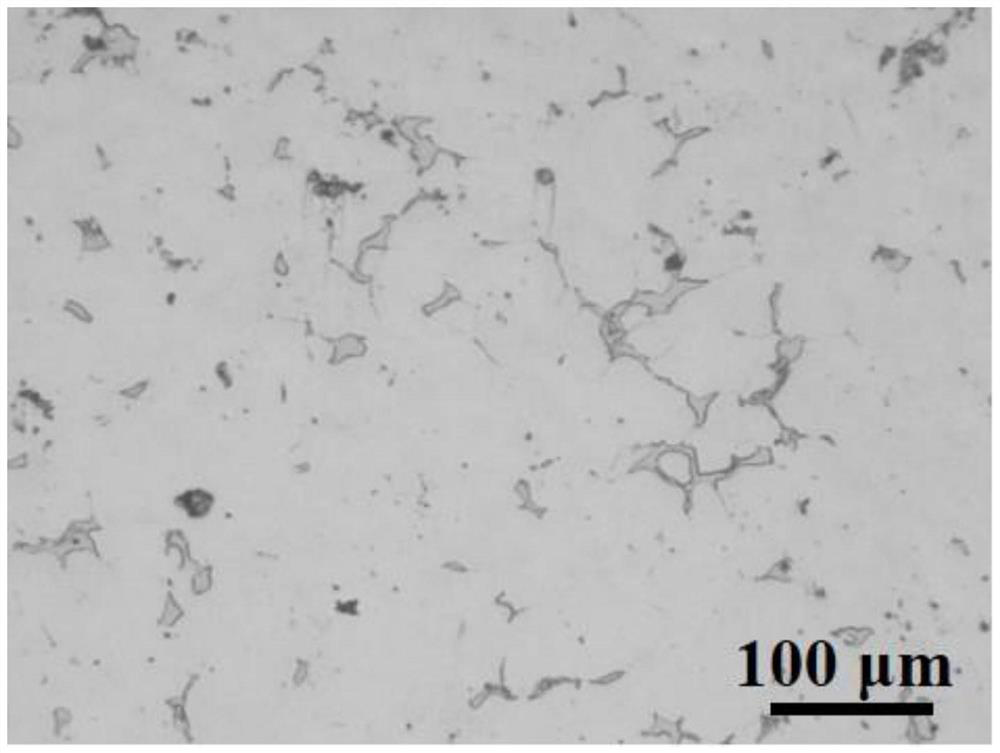

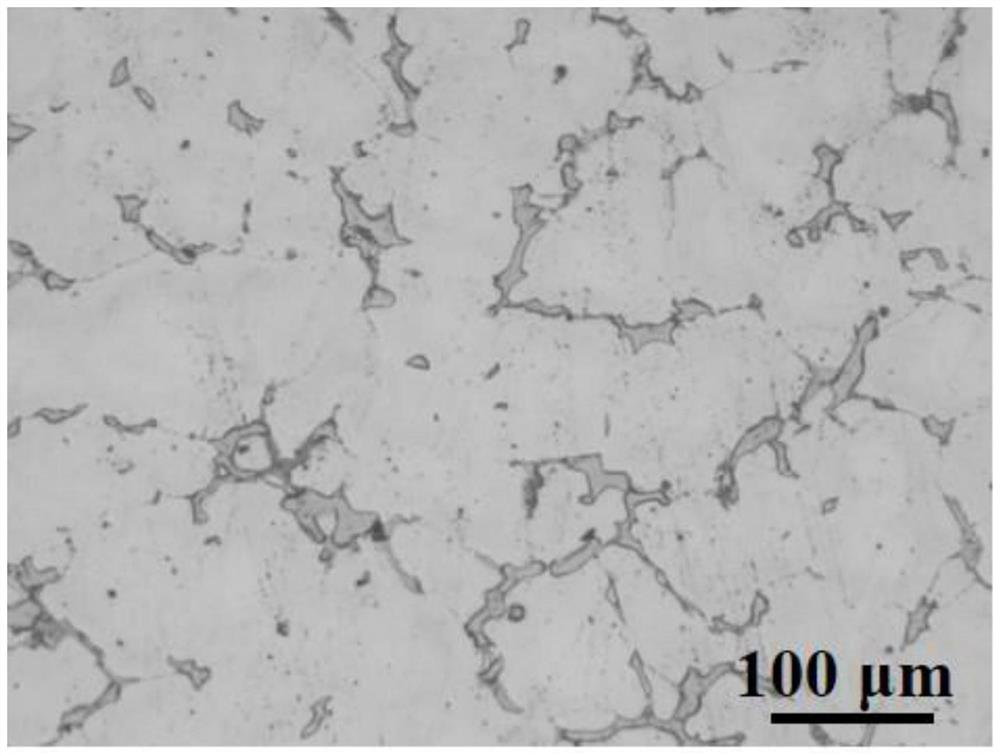

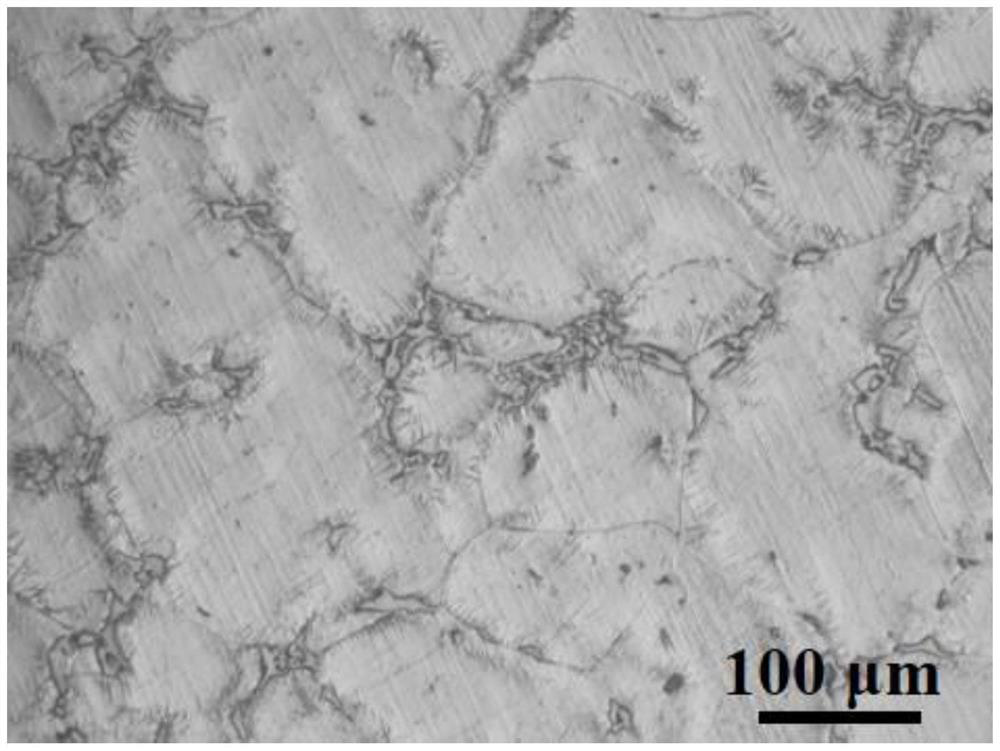

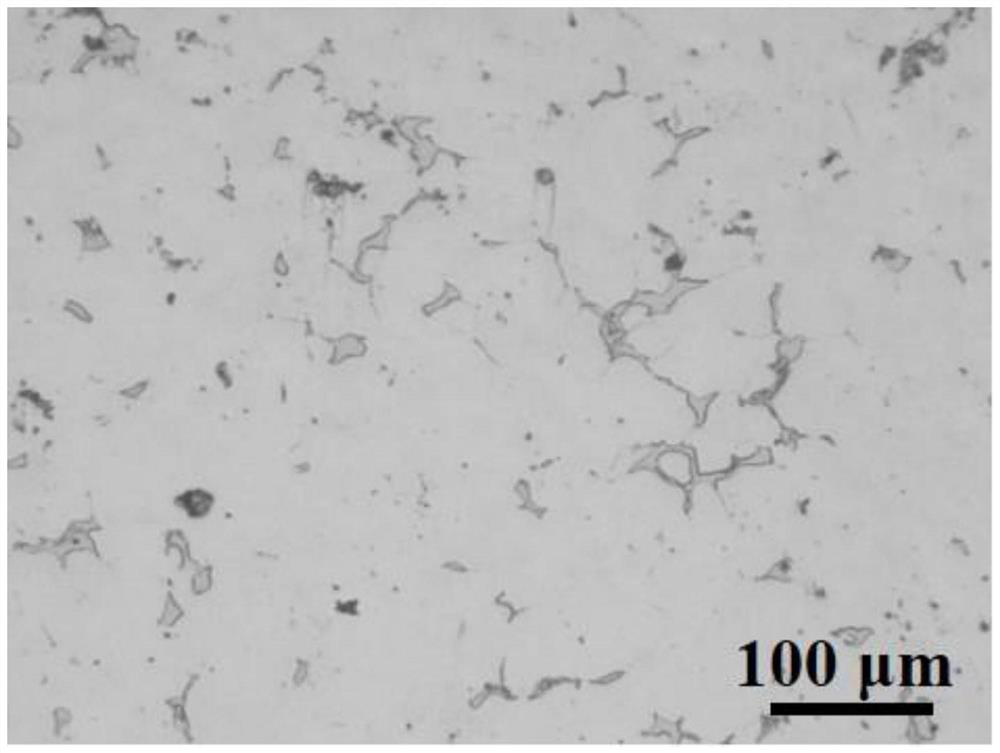

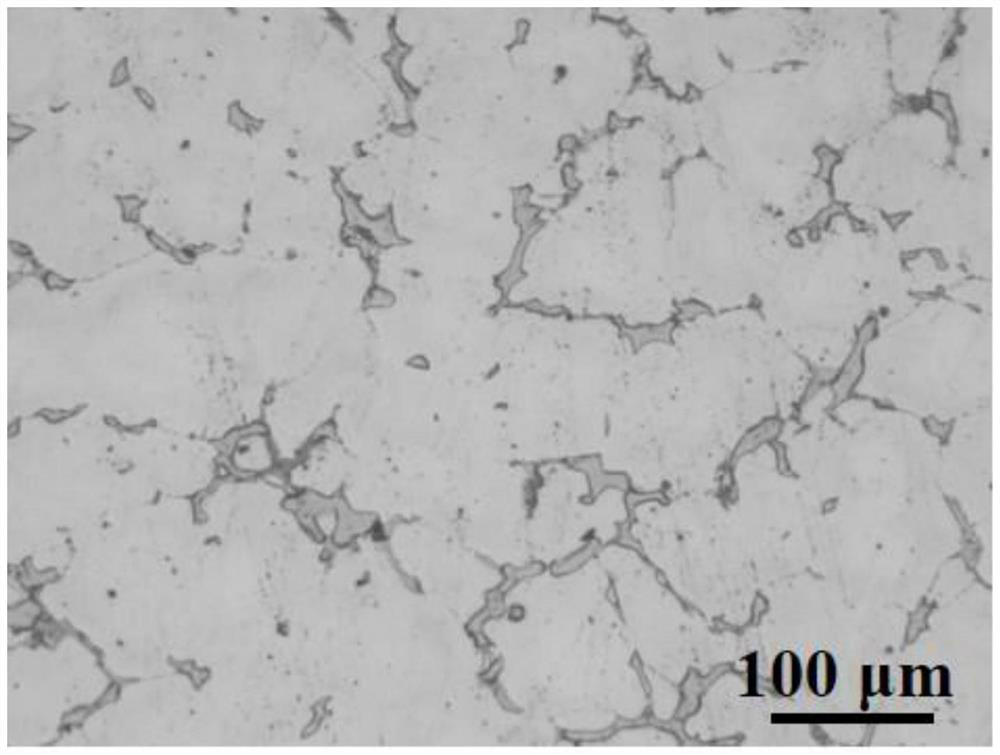

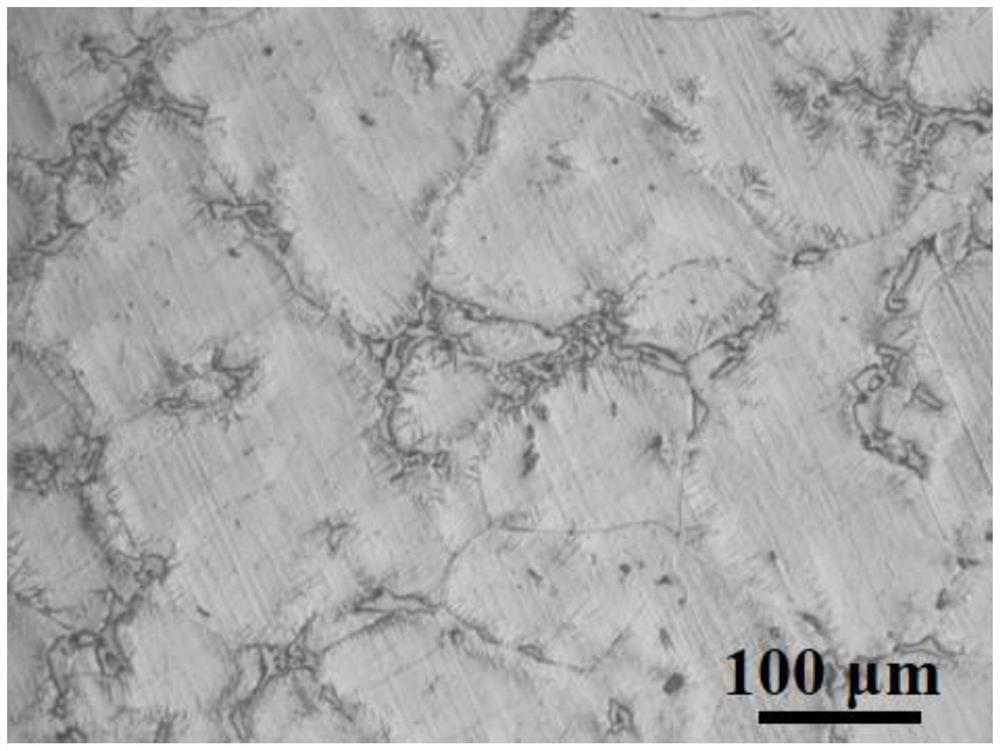

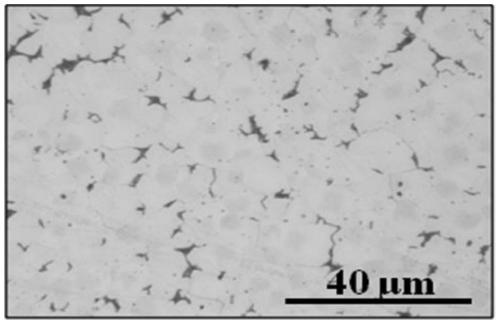

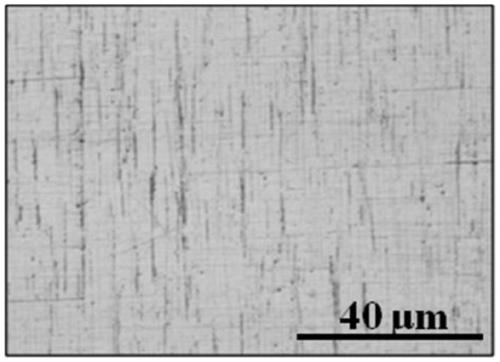

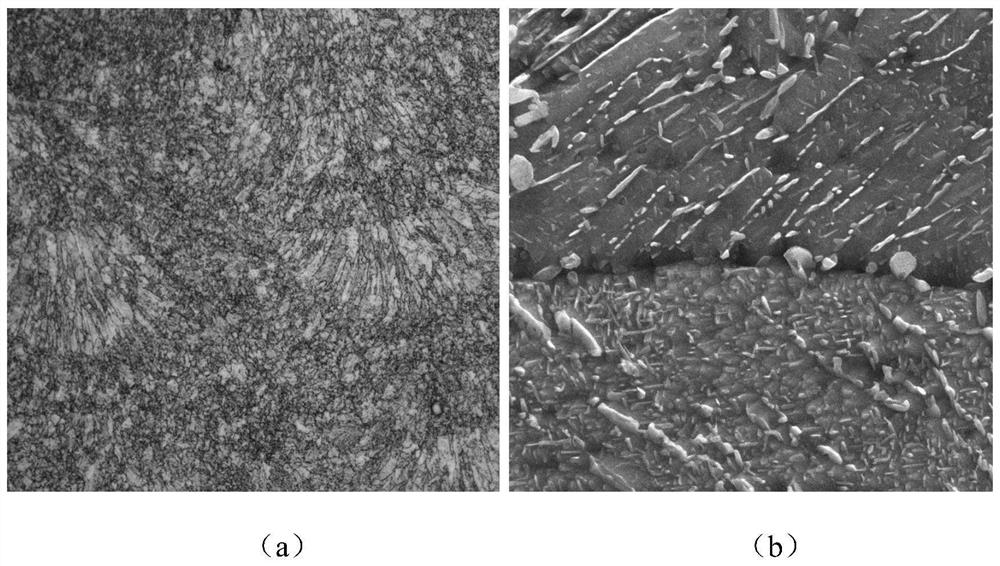

Multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

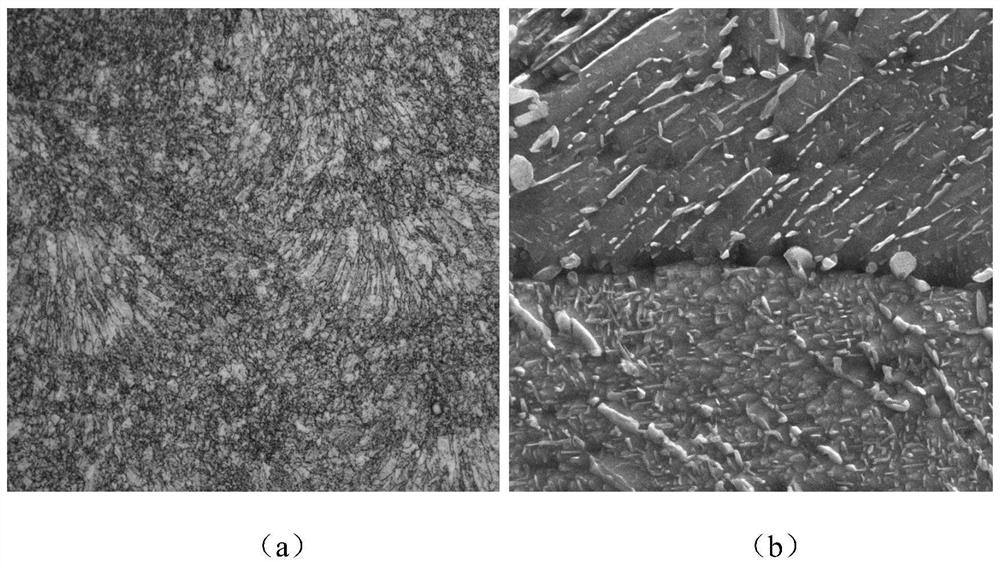

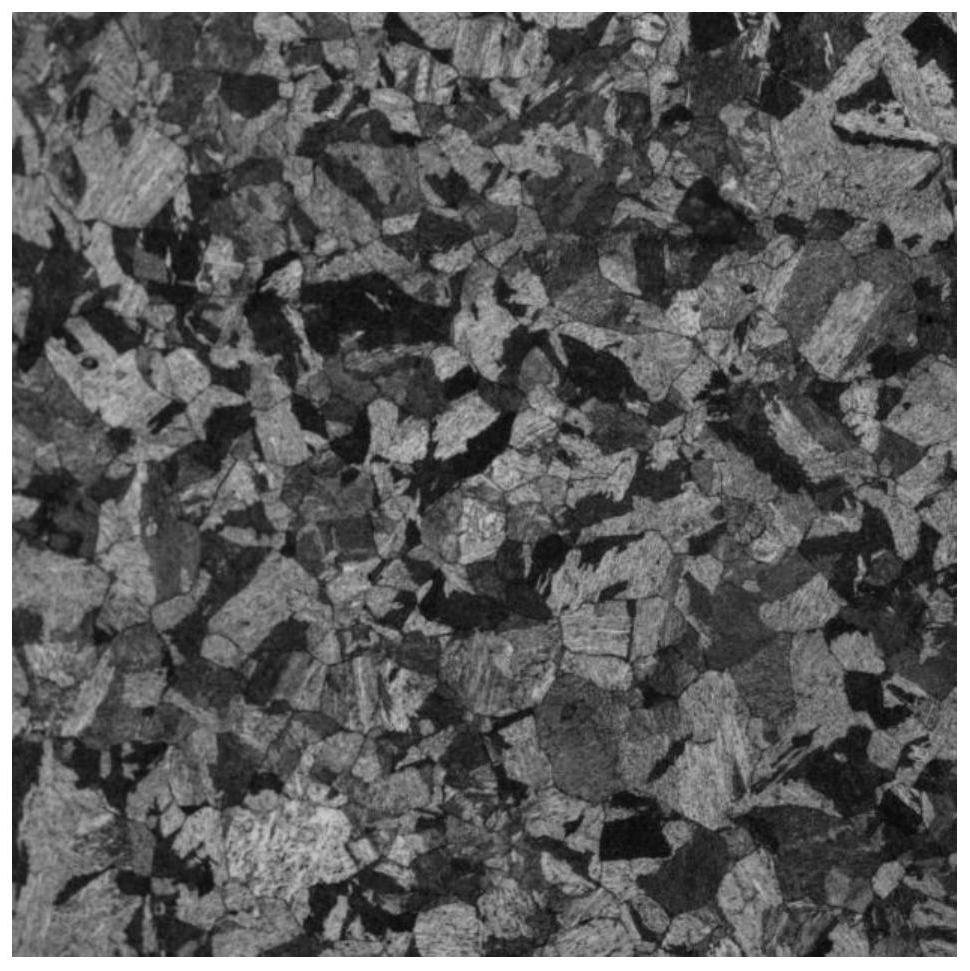

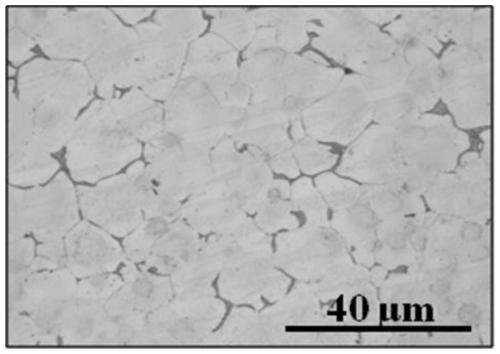

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is a modified Mg-Gd-Y-Zr series rare earth magnesium alloy. The as-cast metallographic structure of the rare earth magnesium alloy is provided with an Mg5Gd phase with a round edge; and or the extruded metallographic structure of the rare earth magnesium alloy has a small granular precipitated phase, and the radial size of the granules is 10-150 nm. The microstructure morphology of the alloy is improved through a multi-element microalloying method, the microstructure morphology of the alloy material is improved by adding trace Ag and Sc in a specific proportion, the age hardening and grain refinement effects are improved, and then excellent room-temperature and high-temperature mechanical properties are obtained. On the premise that the total amount of rare earth is not increased, the strength performance index is high, good plasticity is reserved, engineering application is easy to achieve, and the requirements of the current fields of aerospace, missile military industry, rail transit and the like for the mechanical property of a light structural material under the room-temperature and high-temperature environment can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

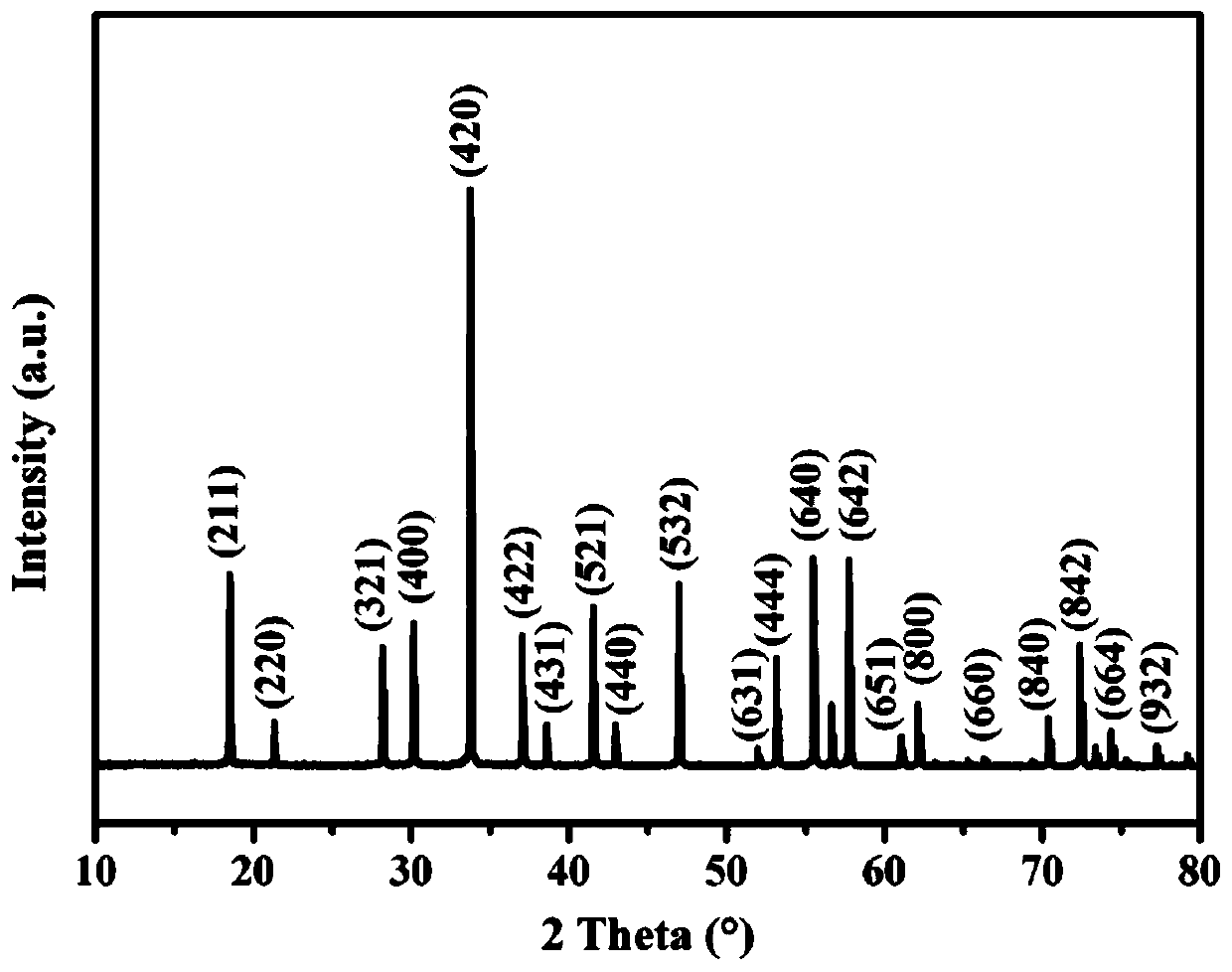

Method for preparing Tb:Lu2O3 ceramic by laser sintering

ActiveCN108751991AAvoid electricity price imbalancesInhibition transitionPolyvinyl alcoholMetallurgy

The invention discloses a method for preparing Tb:Lu2O3 ceramic by laser sintering. The method comprises the following specific steps: separately weighing reaction raw material powder according to thestoichiometric ratio of each element in the chemical structural formula (Lu<1-x>Tbx)2O3, adding citric acid and ethylene glycol into the material mixture, and stirring uniformly to obtain a precursor; then heating the precursor powder, grinding, and calcining by stages; adding a binder, a polyvinyl alcohol solution, into the calcined powder and carrying out dry pressing to obtain a disc-shaped primed piece; placing the primed piece on a Lu2O3 pad, and sintering the both sides of the primed piece by a laser; and finally, grinding and polishing to obtain the Tb:Lu2O3 ceramic. The method provided by the invention can effectively inhibit the conversion of Tb<3+> ions to Tb<4+> ions so as to improve the content of Tb<3+> ions in the ceramic, and realizes high-intensity green light emission under the excitation of 323nm ultraviolet light, the preparation process is simple, energy-saving and environmentally friendly, and the ceramic samples have a relative density of 99.9% and are of high transmittance and good compactness.

Owner:徐州华焰特种陶瓷有限公司

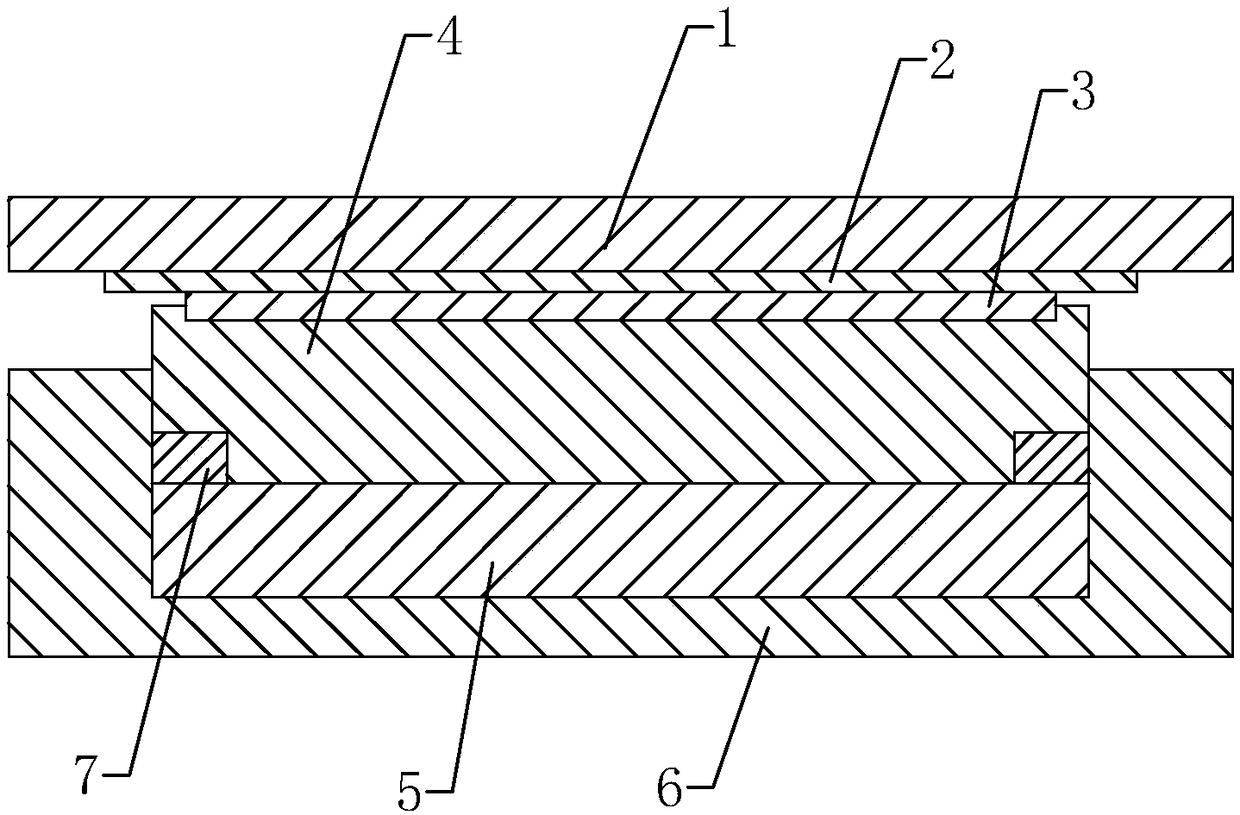

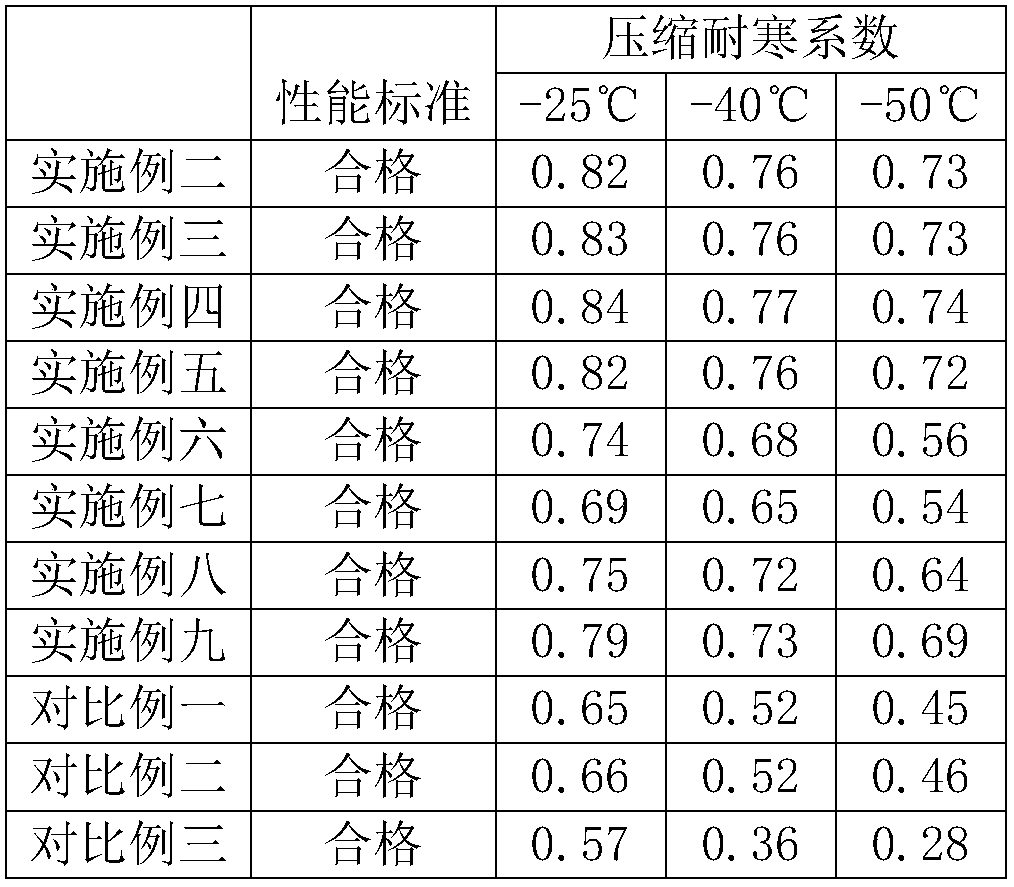

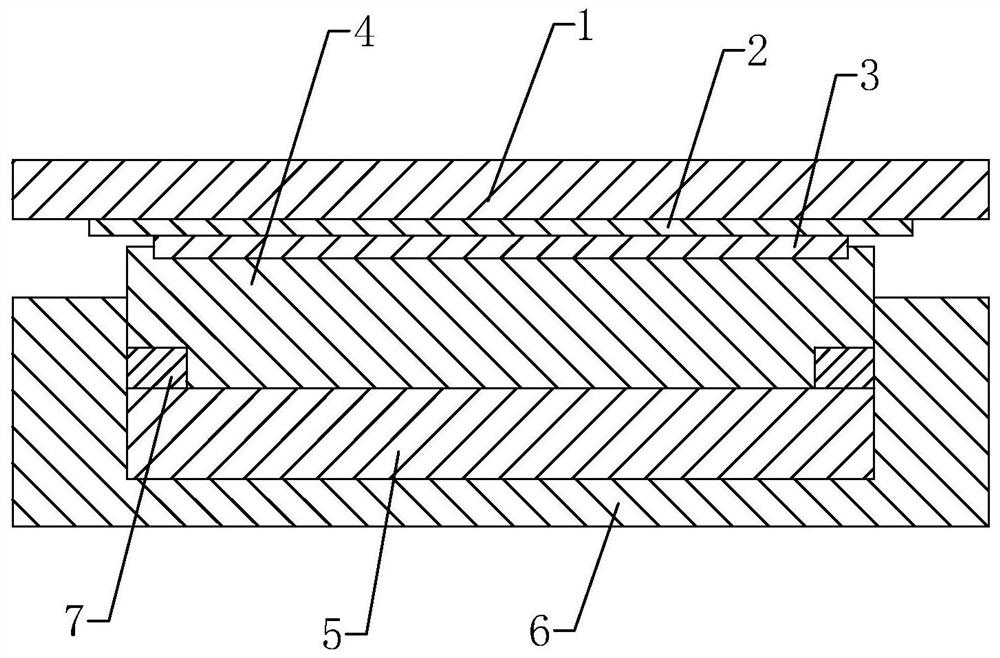

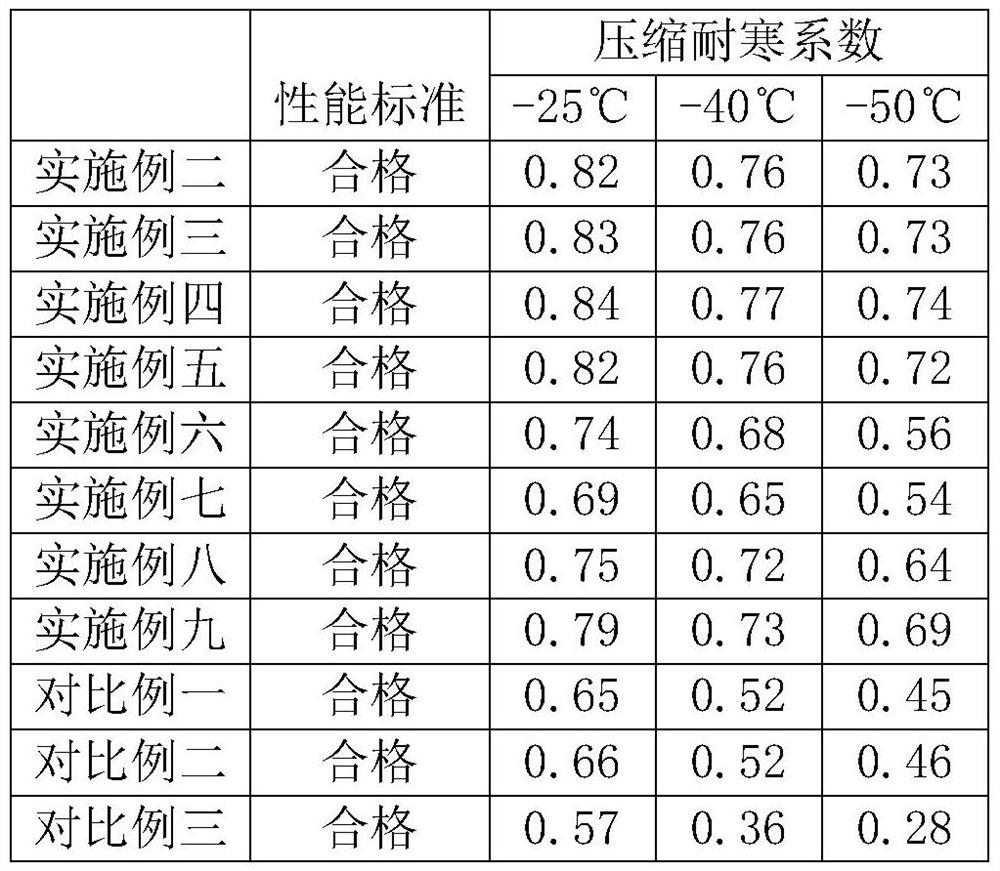

Bridge shock-absorption support

ActiveCN109485931AImprove low temperature performanceMeet the needs of mechanical propertiesBridge structural detailsMicrocrystalline waxRare earth

The invention discloses a bridge shock-absorption support. The bridge shock-absorption support successively comprises a top plate, a stainless steel plate, a polytetrafluoroethylene plate, an intermediate steel plate, a rubber block and a bottom basin, wherein the rubber block is arranged in the bottom basin, a sealing ring is arranged between the rubber block and the intermediate steel plate, therubber block comprises the following components in parts by weight: 60 to 70 parts of natural rubber, 30 to 40 parts of rare-earth cis-polybutadiene, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 2 parts of anti-aging agent, 15 to 25 parts of filler, 0.5 to 1.5 parts of microcrystalline wax, 2 to 3 parts of sulfur, 0.5 to 1 part of accelerant, 3 to 5 parts of plant extract, and 10 to 15 parts of calcium carbonate whisker. After the surface of the calcium carbonate is modified by the plant extract, the calcium carbonate whiskers can be uniformly dispersed among macromoleculesof the rubber, the glass-transition temperature of the natural rubber is shifted to a low-temperature trend, and the low-temperature application performance of the rubber block can be improved.

Owner:温州市龙湾大地绿化有限公司

Flame-retardant heat conduction nylon composite material and preparation method thereof

The invention belongs to the field of materials, and particularly relates to a flame-retardant heat conduction nylon composite material and a preparation method thereof. The lame-retardant heat conduction nylon composite material is prepared from, by weight, 90-150 parts of nylon-6, 30-60 parts of heat conduction filler, 10-15 parts of glass fibers, 30-70 parts of porcelain forming filler, 0.2-0.5part of coupling agent and 0.1-0.2 part of antioxidant; the heat conduction filler includes a component A and a component B; the component A is one of magnesium hydrate, magnesium oxide, zinc oxide,boron nitride and titanium dioxide or an arbitrary composition of magnesium hydrate, magnesium oxide, zinc oxide, boron nitride and titanium dioxide; the component B is boron oxide; the mass ratio ofthe component A to the component B is (4-6):1. The fire-prevention flame-retardant material capable of forming ceramic is adopted to replace traditional flame-retardant agents; when a fire disaster occurs outside, ceramic polymers can be converted into ceramic bodies with compact structures, and the situation is prevented that external flames invade and then cause combustion of internal materials.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Unsaturated polyester resin with excellent mechanical properties for anchoring agent

InactiveCN106366602AMeet the needs of mechanical propertiesImprove mechanical propertiesAnchoring boltsMaleic anhydrideChemistry

The invention discloses an unsaturated polyester resin with excellent mechanical properties for an anchoring agent. The unsaturated polyester resin is prepared from, by weight, 25-35 parts of maleic anhydride, 2-5 parts of isophthalic anhydride, 4-8 parts of tetrachlorophthalic anhydride, 1-5 parts of D-33 monomers, 2-6 parts of benzenetriol, 3-5 parts of hydroquinone, 1-4 parts of cobalt naphthenate styrene, 4-8 parts of melamine polyphosphate, 3-6 parts of methyl ethyl ketone peroxide, 1-6 parts of nano-silica, 3-5 parts of nano-diamond, 4-8 parts of modified carbon nanotubes, 5-15 parts of ethylene glycol, 3-5 parts of diethylene glycol and 4-9 parts of propylene glycol. The unsaturated polyester resin is applied to preparation of the anchoring agent, has excellent mechanical properties and can meet the requirement for mechanical properties in preparation of the anchoring agent.

Owner:安徽鑫力新材科技股份有限公司

Green preparation method of tire rubber powder/polypropylene thermoplastic elastomer

PendingCN113150418ARemove strong odorMeet the needs of mechanical propertiesBuilding insulationsElastomerPolymer science

The invention discloses a green preparation method of a tire rubber powder / polypropylene thermoplastic elastomer. The tire rubber powder / polypropylene thermoplastic elastomer comprises full tire rubber powder; the preparation method comprises the following steps: adding the regeneration activating agent into the whole tire rubber powder, activating in a high-pressure kettle at 120 DEG C, plasticizing polypropylene at 160 DEG C, sequentially adding the sulfur, the compatilizer, the zinc oxide, the stearic acid, the antioxidant 1010 and the environment-friendly softening agent, and uniformly mixing to obtain a premix; adding the mixture into a double-screw extruder at 180 DEG C, carrying out reactive mixing by virtue of a dynamic cross-linking system and strong mechanical shear stress, so as to obtain the tire rubber powder / polypropylene thermoplastic elastomer, and carrying out mold pressing to form sheets. The performance detection shows that the tensile strength reaches 20.12 MPa, the elongation at break reaches 688.57%, the TRP / PP TPE not only has the high elasticity of rubber, but also has the plastic processing characteristic of plastic, and meanwhile, the foul smell of DCP serving as a compatilizer is removed.

Owner:XUZHOU COLLEGE OF INDAL TECH

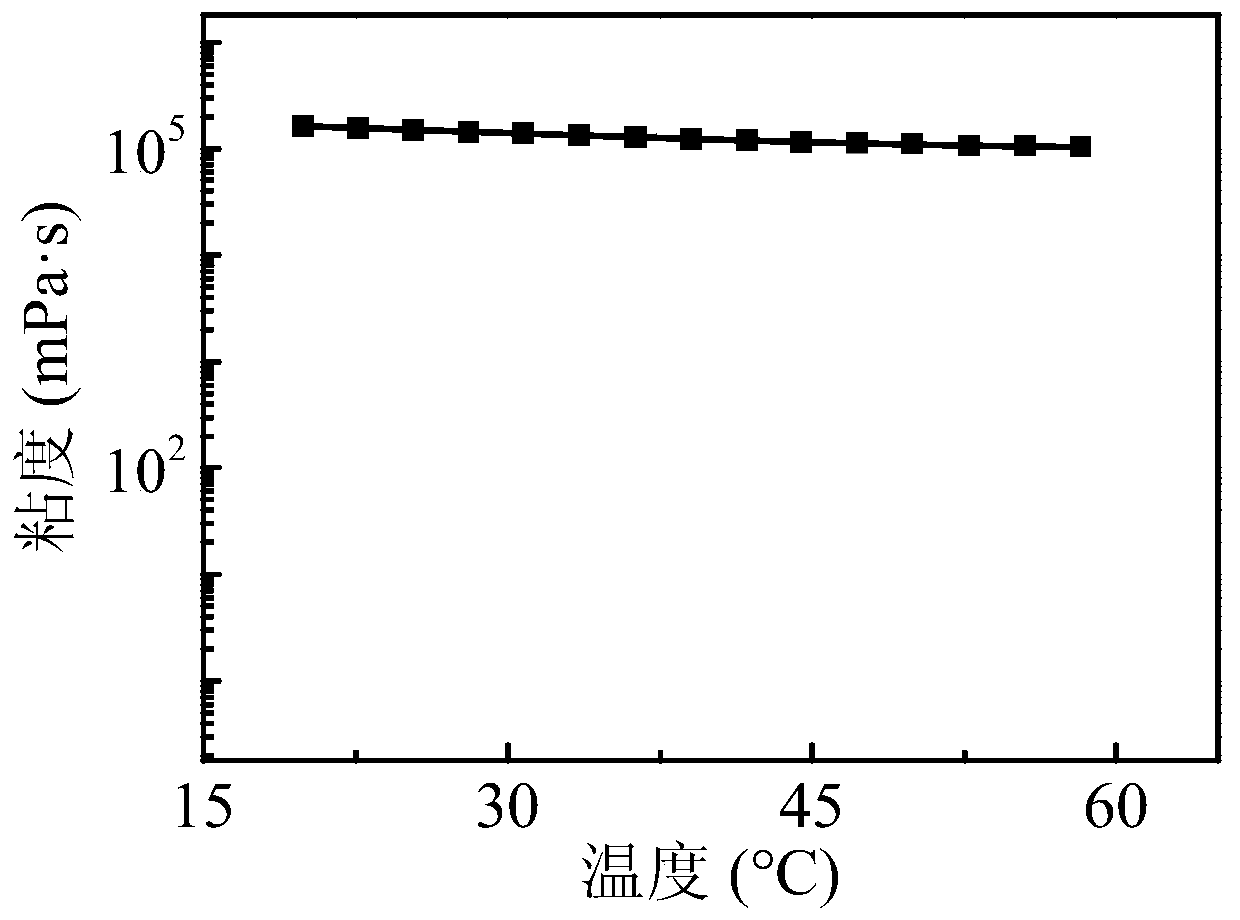

A kind of bioadhesive based on ε-polylysine and its preparation method and application

ActiveCN106110377BGood biocompatibilityImprove liquiditySurgical adhesivesSurgical operationAdhesive

The invention provides a biological adhesive based on epsilon-polylysine as well as a preparation method and application thereof. The adhesive is prepared from epsilon-polylysine, hyaluronic acid and water and is jointly assembled by the epsilon-polylysine and the hyaluronic acid. The biological adhesive provided by the invention has the advantages of safe and toxin-free raw materials, good biocompatibility and capability of being degraded along time; the biological adhesive can be used for replacement of suture lines of medical surgical operations and plastic and aesthetic surgeries; the product can be absorbed by body issues and does not generate toxic side effect; meanwhile, the product has proper elasticity and toughness and meets the requirements on mechanical properties by biological adhesion.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of flame-retardant heat-conducting nylon composite material and preparation method thereof

The invention belongs to the field of materials, and particularly relates to a flame-retardant heat conduction nylon composite material and a preparation method thereof. The lame-retardant heat conduction nylon composite material is prepared from, by weight, 90-150 parts of nylon-6, 30-60 parts of heat conduction filler, 10-15 parts of glass fibers, 30-70 parts of porcelain forming filler, 0.2-0.5part of coupling agent and 0.1-0.2 part of antioxidant; the heat conduction filler includes a component A and a component B; the component A is one of magnesium hydrate, magnesium oxide, zinc oxide,boron nitride and titanium dioxide or an arbitrary composition of magnesium hydrate, magnesium oxide, zinc oxide, boron nitride and titanium dioxide; the component B is boron oxide; the mass ratio ofthe component A to the component B is (4-6):1. The fire-prevention flame-retardant material capable of forming ceramic is adopted to replace traditional flame-retardant agents; when a fire disaster occurs outside, ceramic polymers can be converted into ceramic bodies with compact structures, and the situation is prevented that external flames invade and then cause combustion of internal materials.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

A functional protective gear material used in the field of sports and its preparation method

InactiveCN107057140BImprove wear resistanceImprove heat resistancePolyvinyl chlorideMechanical property

The invention discloses a functional protection tool material used in the sports field and a preparation method of the functional protection tool material, and belongs to the technical field of protection tool materials. The functional protection tool material used in the sports field, which is disclosed by the invention, is prepared from the following raw materials in percentage by weight: 30-45% of nitrile rubber, 15-22% of natural rubber, 15-25% of polyvinyl chloride, 0.5-3% of tourmaline, 0.5-2% of germanite, 0.5-3% of hexacyclic stone, 0.5-3% of green stone, 2-5% of zinc oxide, 0.5-5% of sulfur, 2-6% of high wearing resistance carbon black, 10-20% of white carbon black, 1-3% of an accelerant, 1-3% of an anti-aging agent and 2-6% of glass fiber. The functional protection tool material used in the sports field, which is disclosed by the invention, is not only capable of meeting requirements of mechanical properties, but also is good in wearing resistance, thermal resistance, chemical stability and anti-aging property, meanwhile is capable of promoting blood circulation, and has a constant anion production function.

Owner:HEILONGJIANG UNIV OF TECH

Functional protection tool material used in sports field and preparation method of functional protection tool material

InactiveCN107057140AImprove wear resistanceImprove heat resistancePolyvinyl chlorideChemical stability

The invention discloses a functional protection tool material used in the sports field and a preparation method of the functional protection tool material, and belongs to the technical field of protection tool materials. The functional protection tool material used in the sports field, which is disclosed by the invention, is prepared from the following raw materials in percentage by weight: 30-45% of nitrile rubber, 15-22% of natural rubber, 15-25% of polyvinyl chloride, 0.5-3% of tourmaline, 0.5-2% of germanite, 0.5-3% of hexacyclic stone, 0.5-3% of green stone, 2-5% of zinc oxide, 0.5-5% of sulfur, 2-6% of high wearing resistance carbon black, 10-20% of white carbon black, 1-3% of an accelerant, 1-3% of an anti-aging agent and 2-6% of glass fiber. The functional protection tool material used in the sports field, which is disclosed by the invention, is not only capable of meeting requirements of mechanical properties, but also is good in wearing resistance, thermal resistance, chemical stability and anti-aging property, meanwhile is capable of promoting blood circulation, and has a constant anion production function.

Owner:HEILONGJIANG UNIV OF TECH

A kind of multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

The invention provides a rare earth magnesium alloy, which is a modified Mg-Gd-Y-Zr rare earth magnesium alloy; the as-cast metallographic structure of the rare earth magnesium alloy has rounded edges Mg 5 Gd phase; or, the metallographic structure of the rare earth magnesium alloy in the extruded state has small particle-like precipitates; the radial size of the small particles is 10-150 nm. The invention improves the microstructure and morphology of the alloy through the method of multi-element microalloying, improves the microstructure and morphology of the alloy material by adding a specific proportion of trace Ag and Sc, and improves the effect of age hardening and grain refinement, thereby obtaining excellent room temperature and temperature. High temperature mechanical properties. On the premise of not increasing the total amount of rare earths, the present invention has high strength and performance indexes, retains good plasticity, is easy to realize engineering application, and can meet the requirements for lightweight structural materials in the current aerospace, missile military, rail transit and other fields. Requirements for mechanical properties at room temperature and high temperature.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Thermoplastic elastic material for oil well cement and preparation method thereof

PendingCN114644732AImprove temperature resistanceImprove hardness and brittlenessDrilling compositionPolymer scienceMeth-

The invention provides a thermoplastic elastic material for oil well cement. The thermoplastic elastic material comprises the following raw materials in parts by weight: 100 parts of a thermoplastic elastic material; 100 to 200 parts of a reactive solvent; 10 to 50 parts of a water-soluble monomer; 20 to 100 parts of water; 1-44 parts of a pH regulator; 0.1 to 1 part of an oil soluble initiator; 0.1 to 1 part of a water-soluble initiator; the reactive solvent is one or more of aminopropyl triethoxy silane, 3-methacryloxy propyl trimethylsilane, vinyl trimethoxy silane or vinyl triethoxy silane, and the reactive solvent is one or more of triethoxy silane, 3-methacryloxy propyl trimethylsilane, 3-methacryloxy propyl trimethylsilane, 3-methacryloxy propyl trimethylsilane, 3-methacryloxy propyl trimethylsilane and 3-methacryloxy propyl trimethylsilane; the water-soluble monomer is one or more of acrylic acid, itaconic acid and 2-acrylamido-2-methyl propane sulfonic acid. According to the invention, the thermoplastic elastic material is mixed and dissolved with the reactive solvent, and is subjected to a polymerization reaction with the water-soluble monomer solution, so that the surface of the thermoplastic elastic material has hydrophilic groups, the thermoplastic elastic material has better temperature resistance, and the hardness, brittleness, elasticity and toughness of set cement are improved.

Owner:中石化石油工程技术服务有限公司 +2

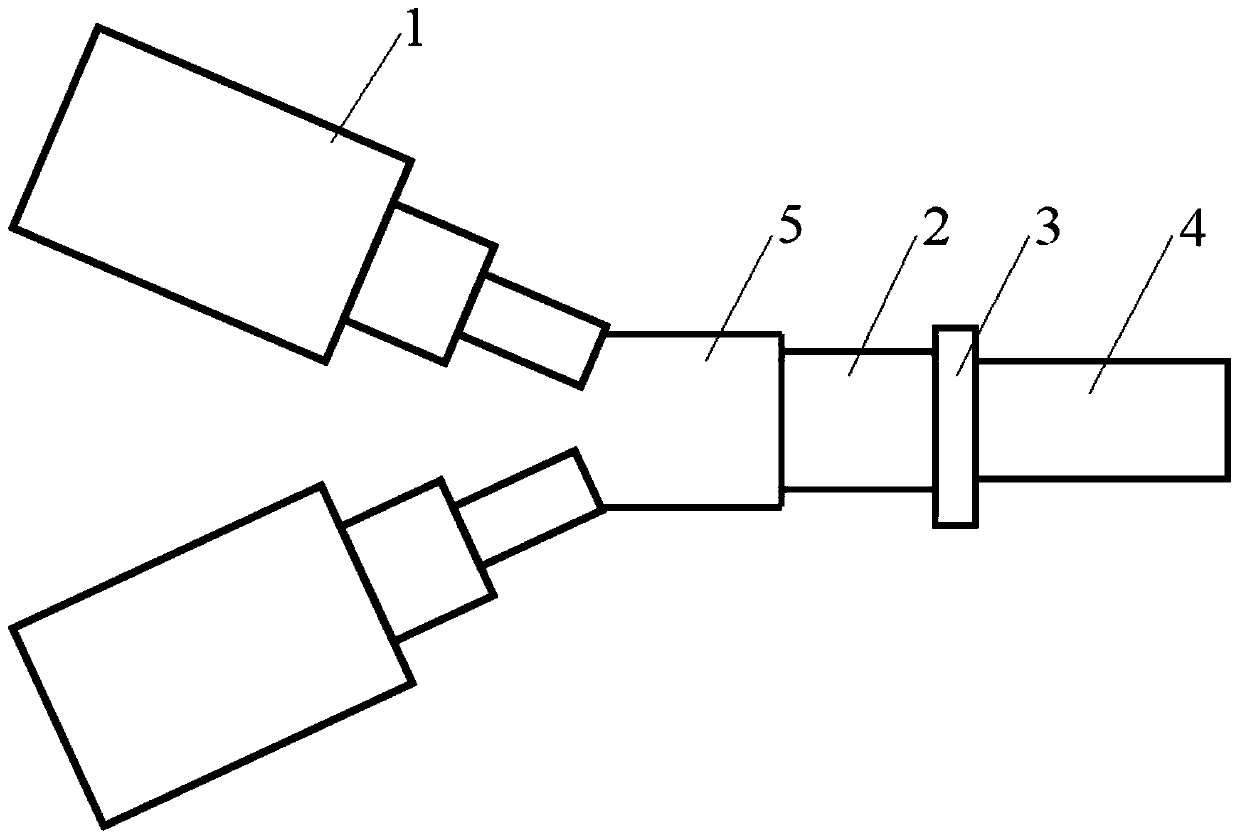

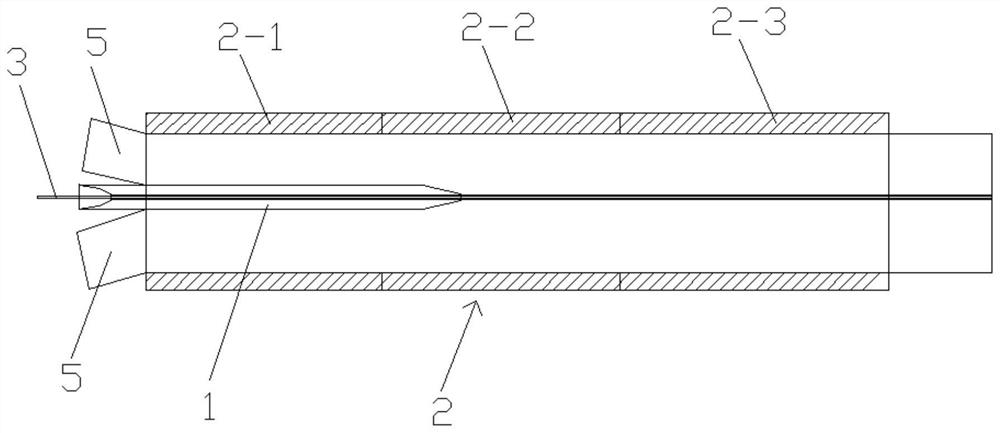

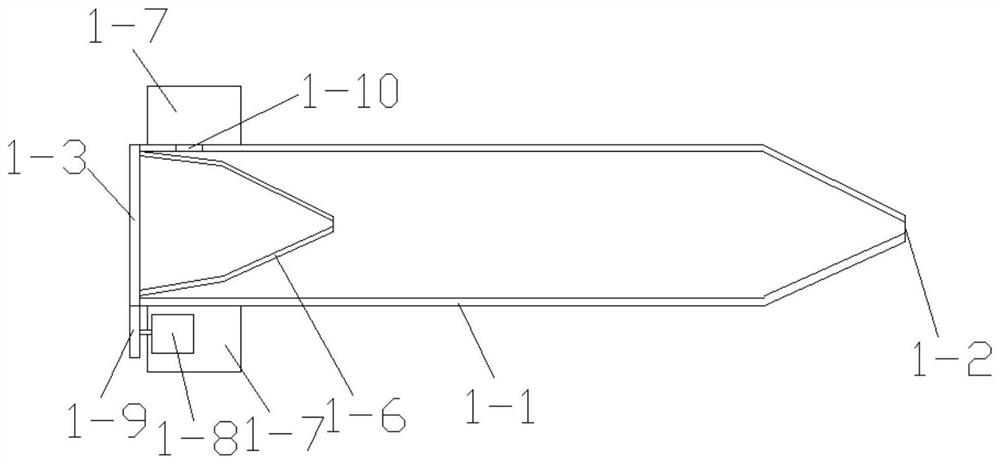

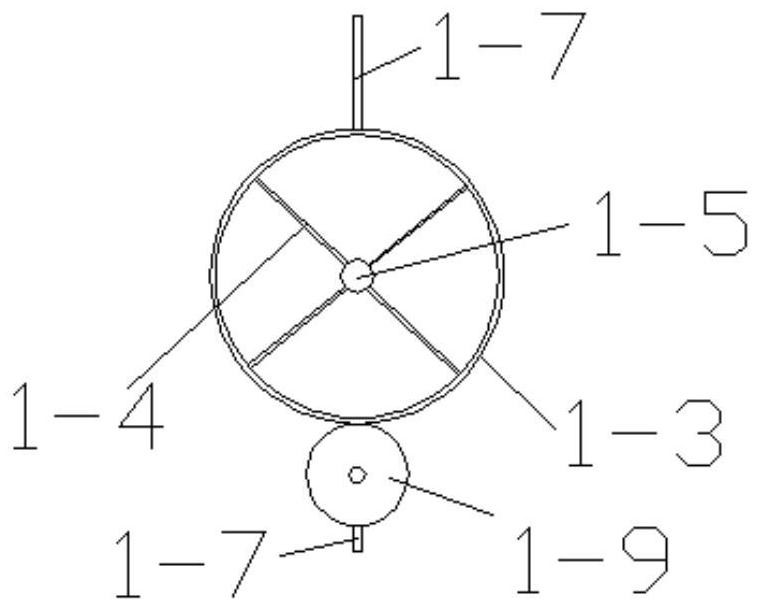

A kind of preparation method of composite core for optical fiber insulator

ActiveCN112712946BAvoid harmEffectively absorb energy lossFibre mechanical structuresInsulatorsEpoxyGlass fiber

The invention discloses a method for preparing a composite core body for an optical fiber insulator. The method comprises the following steps: 1. fixing an optical fiber isolation and protection tool in a pultrusion core mold; 2. passing an optical fiber through the fiber isolation and protection tool and pulling Extrude the core mold to wrap the optical fiber protective layer on the optical fiber; 3. Wrap the optical fiber coated with the optical fiber protective layer in the center of the glass fiber, and then lead it out from the pultruded core mold to obtain a composite core. In the present invention, the optical fiber isolation protection tool is fixed in the pultrusion core mold, and then the optical fiber protective layer is wound on the optical fiber, and then the glass fiber impregnated with epoxy resin glue is passed through, and the optical fiber coated with the optical fiber protective layer is It is clamped and fixed in the center of the glass fiber, and the optical fiber is directly implanted synchronously during the pultrusion process of the glass fiber to avoid the occurrence of fiber breakage, fiber coating damage or insulation seal failure, and protect the optical fiber to ensure that the energy of the light wave will not loss, improving the practicability of the composite core.

Owner:西安高强绝缘电气有限责任公司

Battery diaphragm and preparation method thereof

InactiveCN109802076AAvoid safety hazardsSolve the problem of more through holesCell component detailsMicro nanoSurface layer

The present invention discloses a battery diaphragm and a preparation method thereof. The battery diaphragm of the present invention comprises a micro-nano laminated polyolefin microporous membrane; the micro-nano laminated polyolefin microporous membrane is composed of an upper surface layer, a middle layer and a lower surface layer; and the middle layer is of a multilayer structure formed by polypropylene layers and polyethylene layers through a micro-nano lamination technique. According to the battery diaphragm, the middle layer of the multilayer structure formed by the polypropylene layersand the polyethylene layers through the micro-nano lamination technique is adopted, and therefore, on the one hand, the multi-layer structure has better safety, and on the other hand, the micro-nanolamination technique can assist in improving the tensile strength, puncture strength and other mechanical properties of the battery diaphragm, and can make the battery diaphragm thinner when forming the middle layer, thereby satisfying the requirements of the thin and high-safety lithium battery diaphragm for mechanical properties and safety; and distances from the polyethylene layers in the middle layer to the surface of the battery diaphragm can be adjusted, so that fast breaking functions of different effects can be realized, and therefore, the use requirements of the different breaking functions can be satisfied.

Owner:武汉中兴创新材料技术有限公司

Functional protective equipment material used in sports field and preparation method thereof

The invention discloses a functional protective equipment material used in the sports field and a preparation method thereof and belongs to the technical field of preparation of functional protectiveequipment materials. The functional protective equipment material is prepared from the following raw materials: a styrene-butadiene-styrene block copolymer, nano radium, tourmaline, nanoscale antimonous oxide, chitin, nano silver, toluene diisocynate, glycerol, bamboo carbon fibers, polyether modified organopolysiloxane, amino cyclopropane, 2-methyl triethylene diamine, nonylphenol polyoxyethyleneether, graphene and a silicon dioxide aerogel. The functional protective equipment material is prepared in the steps: mixing, stirring, heating, drying, cooling, forming and the like. The functionalprotective equipment material used in sports field not only can meet the demand on mechanical property, but also is good in wear resistance, heat resistance, chemical stability and anti-ageing property and long in service life.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation of tb:lu by laser sintering 2 o 3 ceramic method

ActiveCN108751991BAvoid electricity price imbalancesInhibition transitionMetallurgyPolyvinyl alcohol

The invention discloses a method for preparing Tb:Lu2O3 ceramic by laser sintering. The method comprises the following specific steps: separately weighing reaction raw material powder according to thestoichiometric ratio of each element in the chemical structural formula (Lu<1-x>Tbx)2O3, adding citric acid and ethylene glycol into the material mixture, and stirring uniformly to obtain a precursor; then heating the precursor powder, grinding, and calcining by stages; adding a binder, a polyvinyl alcohol solution, into the calcined powder and carrying out dry pressing to obtain a disc-shaped primed piece; placing the primed piece on a Lu2O3 pad, and sintering the both sides of the primed piece by a laser; and finally, grinding and polishing to obtain the Tb:Lu2O3 ceramic. The method provided by the invention can effectively inhibit the conversion of Tb<3+> ions to Tb<4+> ions so as to improve the content of Tb<3+> ions in the ceramic, and realizes high-intensity green light emission under the excitation of 323nm ultraviolet light, the preparation process is simple, energy-saving and environmentally friendly, and the ceramic samples have a relative density of 99.9% and are of high transmittance and good compactness.

Owner:徐州华焰特种陶瓷有限公司

A bridge shock absorber

ActiveCN109485931BMeet the needs of mechanical propertiesImprove low temperature resistanceBridge structural detailsMicrocrystalline waxPhysical chemistry

The invention discloses a bridge shock-absorption support. The bridge shock-absorption support successively comprises a top plate, a stainless steel plate, a polytetrafluoroethylene plate, an intermediate steel plate, a rubber block and a bottom basin, wherein the rubber block is arranged in the bottom basin, a sealing ring is arranged between the rubber block and the intermediate steel plate, therubber block comprises the following components in parts by weight: 60 to 70 parts of natural rubber, 30 to 40 parts of rare-earth cis-polybutadiene, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 2 parts of anti-aging agent, 15 to 25 parts of filler, 0.5 to 1.5 parts of microcrystalline wax, 2 to 3 parts of sulfur, 0.5 to 1 part of accelerant, 3 to 5 parts of plant extract, and 10 to 15 parts of calcium carbonate whisker. After the surface of the calcium carbonate is modified by the plant extract, the calcium carbonate whiskers can be uniformly dispersed among macromoleculesof the rubber, the glass-transition temperature of the natural rubber is shifted to a low-temperature trend, and the low-temperature application performance of the rubber block can be improved.

Owner:温州市龙湾大地绿化有限公司

A kind of sc-containing high-strength high-toughness magnesium alloy and preparation method thereof

ActiveCN109022983BImprove mechanical properties at room temperatureHigh tensile strengthMischmetalRare-earth element

The invention provides a high-strength and high-toughness magnesium alloy containing Sc, which comprises the following components in mass fraction: Y: 4.5-6.5 wt%, Nd: 1.5-4.0 wt%, Gd: 1.5-4.0 wt%, Sc: 0.05 ~0.5wt%, Zr: 0.15~1.5wt%, the balance is Mg, wherein the total amount of rare earth elements does not exceed 10wt%. The high-strength and high-toughness magnesium alloy component in the present invention is Mg-Y-Nd-Gd-Sc-Zr, with the precipitation strengthening of rare earth-containing intermetallic compounds as the main strengthening mechanism, and by adding non-rare earth element Sc to improve the material of the present invention The nucleation density during solidification significantly refines the alloy structure. The material of the invention has excellent mechanical properties at room temperature and high temperature, and has higher plasticity among similar materials. The invention also provides a preparation method of the Sc-containing high-strength and high-toughness magnesium alloy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of mirror-faced aluminum strip material for automotive interior parts and preparation method thereof

ActiveCN111085561BPromote random distributionAchieve no shading defectsUltimate tensile strengthHeat treated

The invention provides a mirror-faced aluminum plate strip for automobile interior parts and a preparation method thereof. The preparation steps of the aluminum material are as follows: melting and casting, homogenization and heating integrated heat treatment, hot rolling, cold rolling, mirror rolling and finished product annealing. The grain size in the metal structure of the aluminum material is fine, the texture distribution is random, and the second phase distribution is uniform. Its surface has no shading defects, showing a mirror effect, roughness ≤ 0.02μm, gloss ≥ 750GU; tensile strength 100-130MPa, yield strength ≥ 70MPa, elongation ≥ 30%. All performance indexes of the aluminum material meet the requirements for the use of automotive interior parts.

Owner:中铝河南洛阳铝加工有限公司 +1

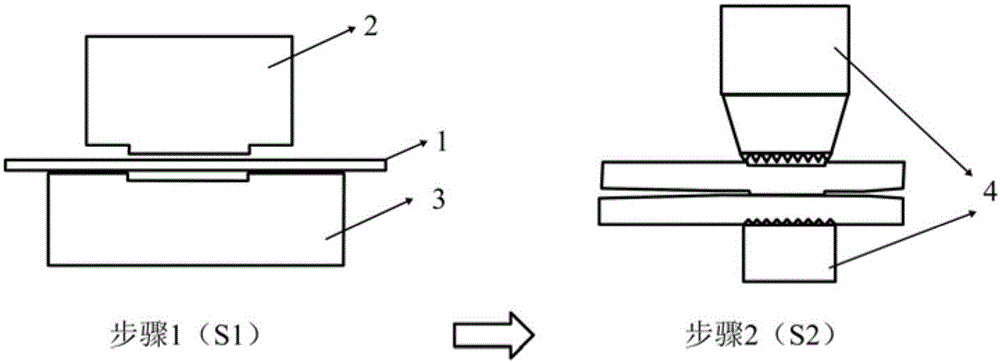

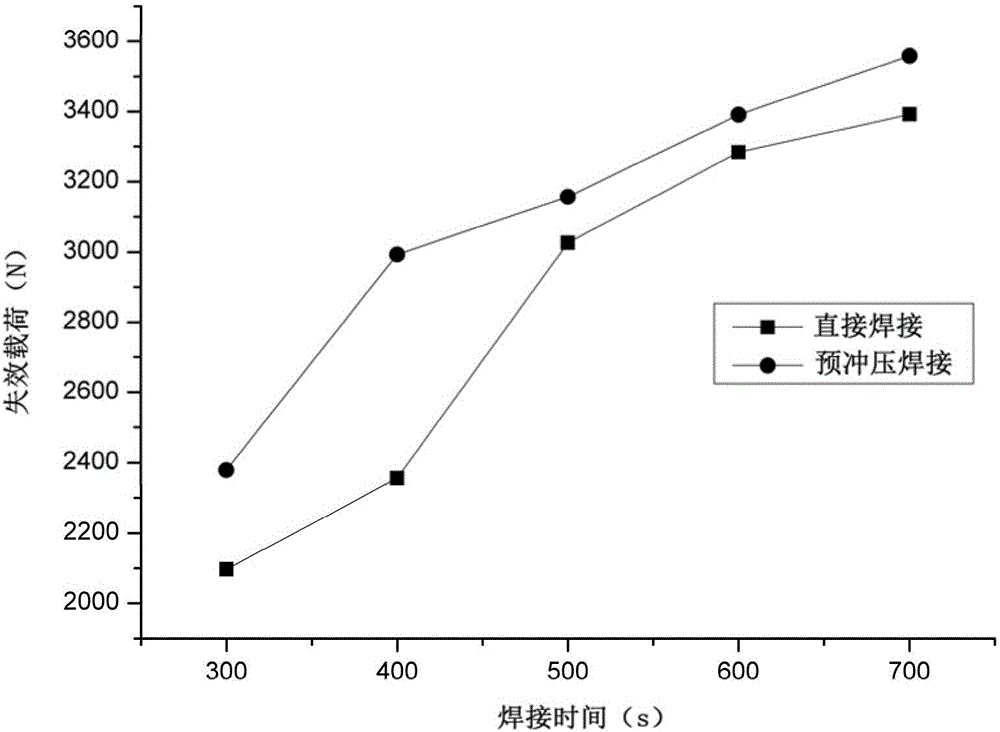

Ultrasonic metal welding method adopting pre-stamping deformation treatment

InactiveCN106312289AReduce energy required for deformationEliminate frictionNon-electric welding apparatusLap jointEngineering

The invention provides an ultrasonic metal welding method adopting pre-stamping deformation treatment. The ultrasonic metal welding method adopting the pre-stamping deformation treatment comprises the following steps that a plate to be welded is placed in a mold to be fixed and limited, pre-deformation treatment is conducted on the plate to be welded, and the back face of the plate to be welded is made to generate a boss which is in a preset shape and has a preset height; and the plate obtained after the pre-deformation treatment is in lap joint with a foundation plate to be welded, an ultrasonic welding head is moved to a pre-deformation treatment position to conduct welding, and finally a uniform and firm welded joint is obtained. According to the ultrasonic metal welding method adopting the pre-stamping deformation treatment, the pre-deformation treatment is conducted on the plate to be welded firstly, and then welding is conducted; in this way, a welding spot is stressed more evenly in the welding process, energy is concentrated better on the welding spot, so that the welding strength is improved, and the welding energy consumption is reduced; and besides, welding spots of different shapes can be formed, and the structural component design requirements are met.

Owner:DALIAN UNIV OF TECH

A kind of high heat conduction high-strength co-fe-ni alloy for mold and additive manufacturing method thereof

ActiveCN112301255BMake up for the disadvantage of high costMaintain steel mechanical propertiesAdditive manufacturing apparatusTransportation and packagingEconomic benefitsAlloy

The invention relates to a high thermal conductivity and high-strength Co-Fe-Ni alloy for a mold and its additive manufacturing method. According to the weight percentage, its chemical composition is as follows: C 0-0.01%, Ni 12-18%, Fe 38-42% , Cr 0‑1.2%, X 0‑0.05%, P<0.015%, S<0.010%, the balance is Co and unavoidable impurities; where X=Sc, and / or Y, and / or Nd, and / or or Pd. Compared with the prior art, the present invention applies Co-based medium-entropy alloys to molds, utilizes additive manufacturing and subsequent heat treatment to adjust and control different strength and toughness combinations, and maintains the same level of existing mold steel without greatly increasing costs. Under the premise of mechanical properties, the thermal conductivity and service reliability of the alloy are improved, and it can replace some of the current mold steels, which has considerable economic benefits.

Owner:SHANGHAI ESU LASER TECH CO LTD

A high-strength heat-resistant magnesium alloy containing ag and its preparation method

ActiveCN108624793BImprove mechanical properties at room temperatureHigh tensile strengthMischmetalRare-earth element

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com