A bridge shock absorber

A shock-absorbing bearing and bridge technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of not being able to apply cold-resistant basin rubber bearings, poor cold resistance of rubber blocks, and elastic loss, etc., to achieve Improve low temperature resistance, improve low temperature performance, and meet the needs of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

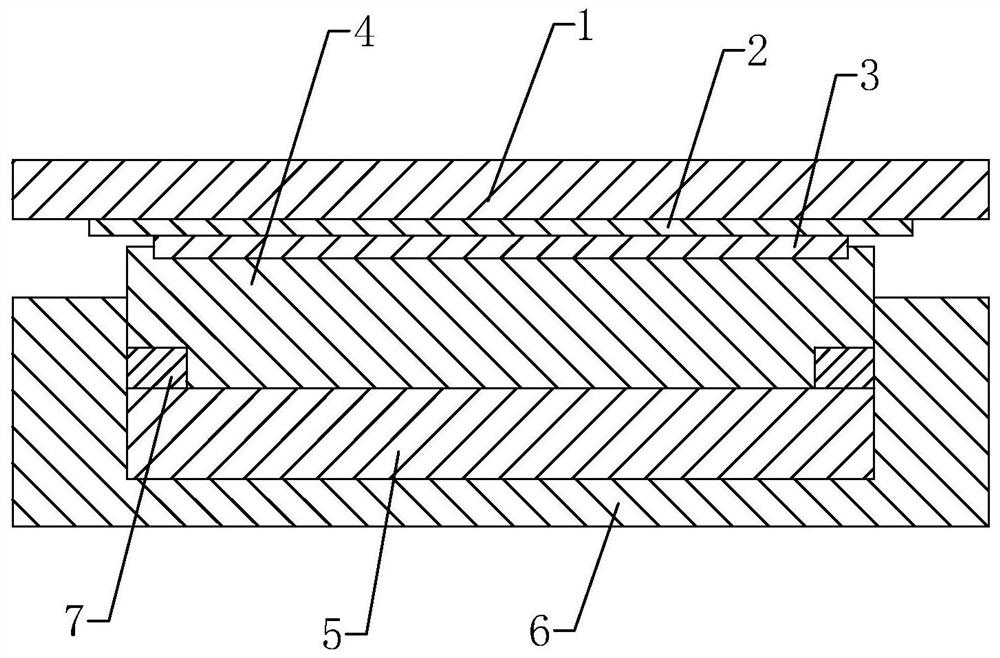

[0050] A bridge shock absorbing support, such as figure 1 As shown, from top to bottom, the top plate 1, the stainless steel plate 2, the polytetrafluoroide 3, the intermediate steel plate 4, the rubber block 5, and the bottom basin 6 are sequentially included. The rubber block 5 is placed at the bottom of the bottom basin 6, and the intermediate steel sheet 4 is disposed in the bottom basin 6, and the rubber block 5 and the intermediate steel plate 4 are provided with a seal ring 7.

Embodiment 2

[0052] The rubber block in Example No. 1 includes components of the following weight:

[0053] 60 parts of natural rubber;

[0054] 30 copies of rare earth relief rubber, model ND45, purchased from South Korea LG Chem;

[0055] 3 copies of zinc oxide;

[0056] 1 stearic acid;

[0057] Anti-aging agent BLE 1;

[0058] Carbon black N330 15 copies;

[0059] 0.5 microcrystalline wax;

[0060] Sulfur 2 parts;

[0061] Accelerator DM 0.5 parts;

[0062] 3 parts of plant extract;

[0063] Calcium carbonate, 10 parts, model NP-CW2, purchase from Shanghai Fengzhu Composite New Material Technology Co., Ltd.

[0064] 3 parts of dimethylphthylsylsilane;

[0065] 2 parts of dibutyl sebacate.

[0066] The preparation process of plant extract is as follows:

[0067] Step 1, take the larch bark and put it in a cool and ventilated ventilation, then crush until the end, over 100 mesh sieve, get crushing;

[0068] Step 2, mixing the crushed material and a 75% ethanol solution of 10 times the weight o...

Embodiment 3

[0080] The rubber block in Example No. 1 includes components of the following weight:

[0081] 70 natural rubber;

[0082] 40 parts of rare earth relief rubber, model ND45, purchased from Korea LG Chem;

[0084] 3 copies of stearic acid;

[0085] 2 copies of the aging agent BLE;

[0086] Carbon black N330 25 copies;

[0087] 1.5 parts of microcrystalline wax;

[0088] 3 parts of sulfur;

[0089] Promotive DM 1;

[0090] 5 parts of plant extract;

[0091] 15 copies of calcium carbonate, model NP-CW2, purchased from Shanghai Fengzhu Composite New Material Technology Co., Ltd.

[0092] 6 parts of dimethylphthylsylsilane;

[0093] 5 parts of dibutyl sebacate.

[0094] The preparation process of plant extract is as follows:

[0095] Step 1, take the larch bark and put it in a cool and ventilated ventilation, then crush until the end, over 100 mesh sieve, get crushing;

[0096] Step 2, mixing the crushed material with a 75% ethanol solution of 15 times the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com