Ultrasonic metal welding method adopting pre-stamping deformation treatment

A deformation treatment and metal welding technology, which is applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of high welding energy consumption and difficult interface flow, so as to increase the welding process window, reduce welding energy consumption, eliminate friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

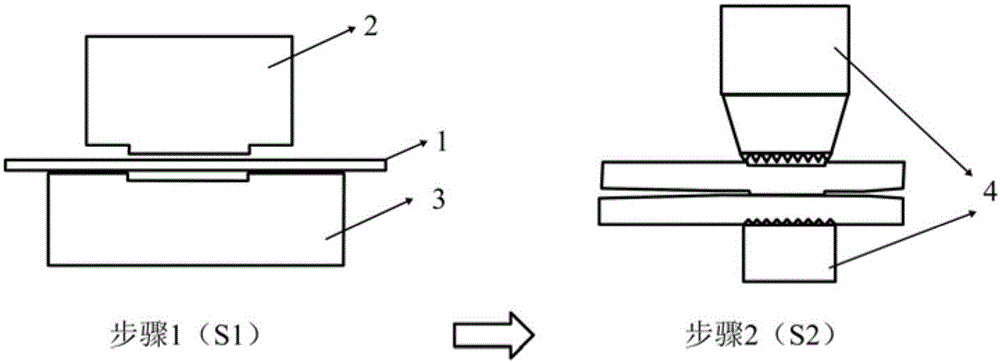

[0033] Using the present invention to weld the magnesium alloy plate structure, the preparation process includes the following steps:

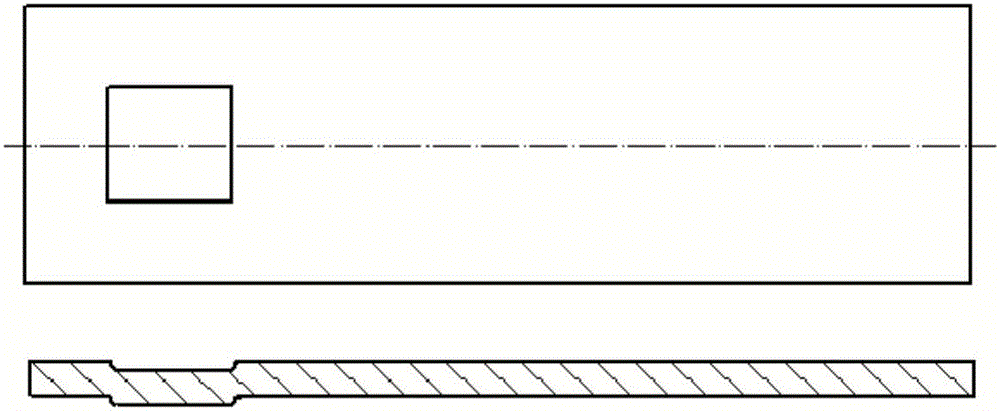

[0034] S1. Put the magnesium alloy plate 1 into the mold, clamp and fix the magnesium alloy plate 1 through the upper mold 2 and the lower mold 3, and then start stamping, and keep the displacement for 5s. After the stamping, the measured pressing force of the plate is: 0.10mm, the obtained plate surface is as figure 2 shown.

[0035] S2. Put the pre-deformed test piece (upper plate) and the base plate (lower plate) to be welded into the welding machine 4, position the pre-stamped position of the upper plate corresponding to the welding head, and start ultrasonic welding , high-strength joints can be obtained after welding.

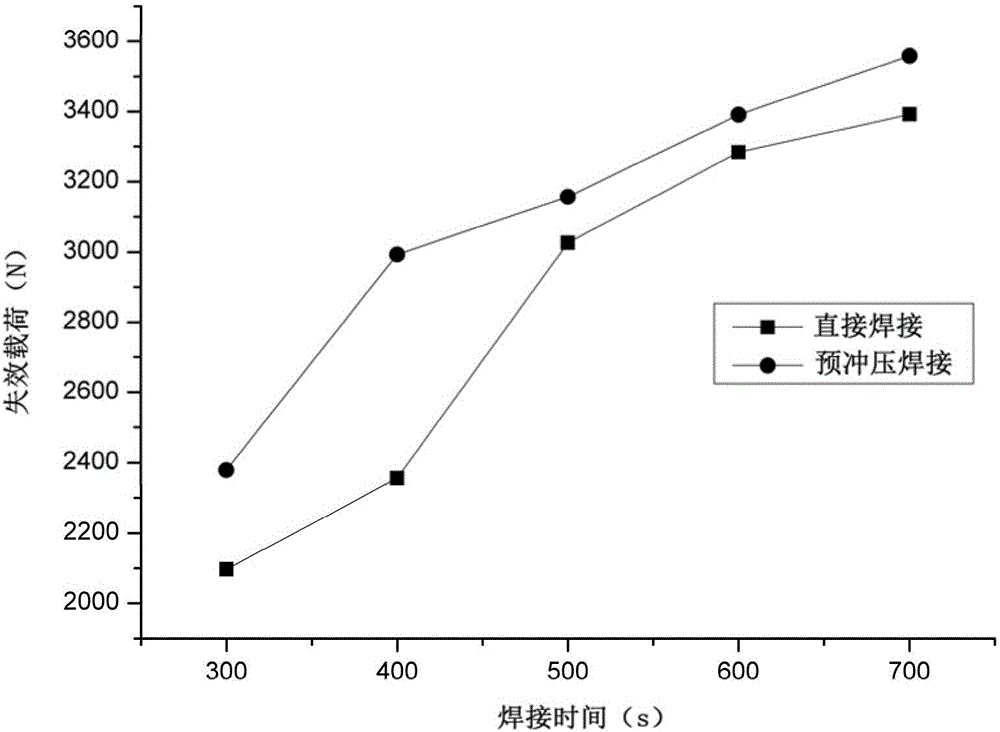

[0036] Using different welding time methods to compare the influence of pre-stamping on welding strength, the results obtained are as follows image 3 shown. It can be seen that the joint strength after pre-stamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com