A high-strength heat-resistant magnesium alloy containing ag and its preparation method

A magnesium alloy, high-strength technology, applied in the field of high-strength heat-resistant magnesium alloy and its preparation, can solve the problems that are difficult to meet the needs of precision manufacturing and reduce the plasticity of the alloy, and achieve the improvement of age hardening effect and heat resistance, high temperature performance, good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing an Ag-containing high-strength heat-resistant magnesium alloy, comprising the following steps:

[0051] A) batching pure Mg, pure Ag, Mg-Zr master alloy and Mg-RE master alloy according to the following mass fractions, melting and casting;

[0052] RE = Y, Nd and Gd;

[0053] Y: 4.5~6.5wt%, Nd: 1.5~4.0wt%, Gd: 1.5~4.0wt%, Ag: 0.1~1.5wt%, Zr: 0.15~1.5wt%, the balance is Mg, of which the total amount of rare earth elements Not more than 10wt%;

[0054] B) heat-treating or extruding the casting to obtain a high-strength heat-resistant magnesium alloy containing Ag.

[0055]In the present invention, the pure Mg, the pure Ag, the Mg-Zr master alloy and the Mg-RE master alloy are preferably proportioned and then dried, the drying temperature is 100-200°C, and the drying time is 1-2 hours;

[0056] (2) Put the dried pure Mg, pure Ag, and Mg-RE master alloy into the crucible and raise the temperature with the furnace...

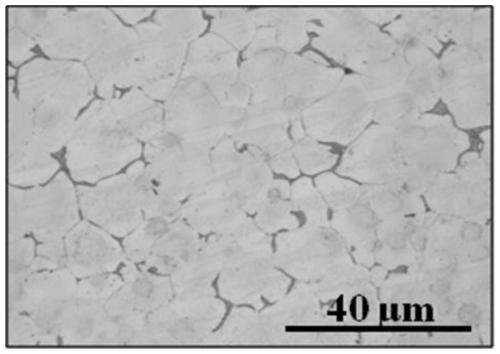

Embodiment 1

[0076] The high-strength heat-resistant magnesium alloy in this embodiment is composed of the following components in mass percentage: Y: 4.5wt%, Nd: 1.5wt%, Gd: 1.5wt%, Ag: 0.1wt%, Zr: 0.5wt%, and the balance is Mg and unavoidable impurities.

[0077] The casting molding preparation of the high-strength heat-resistant magnesium alloy of this embodiment comprises the following steps:

[0078] (1) The raw materials pure Mg, pure Ag, Mg-Zr master alloy, and Mg-RE (20wt.%) master alloy are prepared according to the proportion, and then dried. The drying temperature is 200° C., and the drying time is 2 hours.

[0079] (2) During the preparation process, the melt has been in CO 2 and SF 6 Under the protection of mixed gas, CO 2 with SF 6 The ratio is 99.5:0.5.

[0080] (3) Put the dried pure Mg, pure Ag, and Mg-RE (20wt.%) master alloy into a crucible and heat up with the furnace until it is completely melted, and the temperature is controlled at 780°C.

[0081] (4) Cool the ...

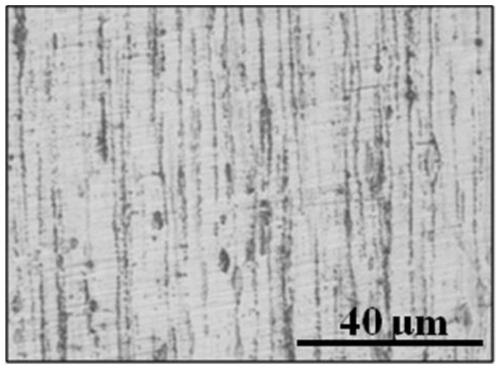

Embodiment 2

[0087] The difference between Example 2 and Example 1 is that the high-strength heat-resistant magnesium alloy consists of the following components by mass percentage: Y: 6.5wt%, Nd: 1.5wt%, Gd: 1.5wt%, Ag: 0.5wt%, Zr: 0.5wt%, the balance is Mg and unavoidable impurities.

[0088] Solution treatment: heat-treat the casting at 510°C for 12h, then air-cool to room temperature. Aging treatment: heat-treat the casting at 225°C for 48 hours, then air-cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com