Preparation of tb:lu by laser sintering 2 o 3 ceramic method

A laser sintering, lu2o3 technology, applied in the field of ceramic material preparation, can solve the problems of large size (10-30μm, affecting the luminous quality of ceramics, poor mechanical properties, etc., achieve good mechanical properties, avoid electricity price imbalance, inhibit Tb4+ The effect of the generation of ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

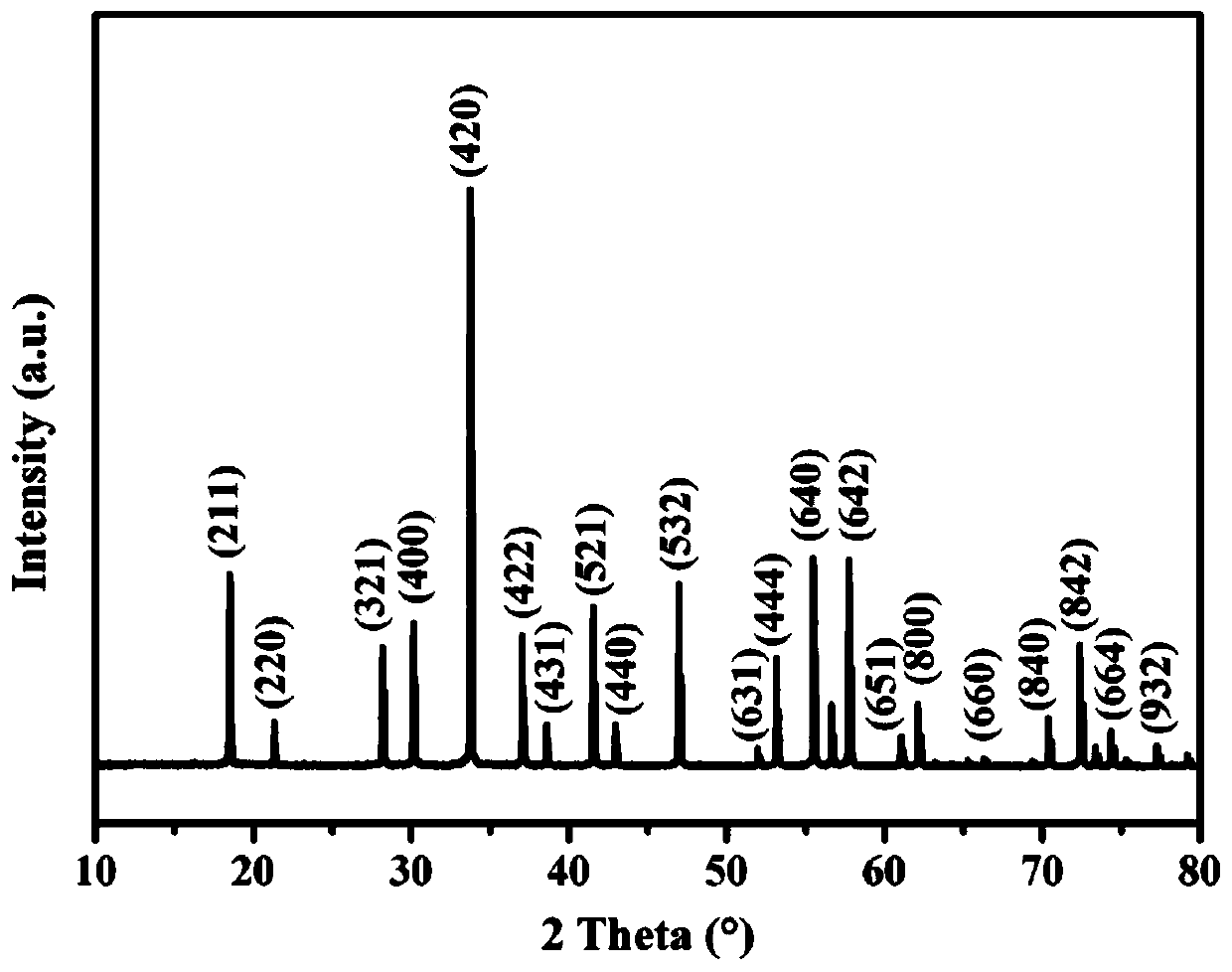

Image

Examples

Embodiment 1

[0026] Embodiment 1: (Lu 0.999 Tb 0.001 ) 2 o 3 transparent ceramic

[0027] According to (Lu 0.999 Tb 0.001 ) 2 o 3 The stoichiometric ratio of each element in is weighed Lu respectively 2 o 3 and Tb 4 o 7 Powder as reaction raw material;

[0028] Dilute citric acid with distilled water to a concentration of 0.05g / ml, add citric acid and ethylene glycol solution (the mol ratio of metal ion and citric acid is 0.2, and the mass ratio of citric acid and ethylene glycol is 1 ), and stir evenly to obtain a precursor solution;

[0029] Heat the precursor solution to 70 ° C for 24 hours to remove excess water, cool it to room temperature, and then place it in a mortar for grinding to obtain a precursor powder; then pre-prepared the ground precursor powder at 500 ° C Calcined for 5 h to remove excess organic matter, and then the pre-calcined precursor powder was placed in a muffle furnace and calcined at 800°C for 1 h.

[0030] Add 0.05g / ml of binder polyvinyl alcohol (...

Embodiment 2

[0033] Embodiment 2: (Lu 0.995 Tb 0.005 ) 2 o 3 transparent ceramic

[0034] According to (Lu 0.995 Tb 0.005 ) 2 o 3 The stoichiometric ratio of each element in the 3 ) 3 ·6H 2 O and Tb(NO 3 ) 3 ·5H 2 O powder as a reaction raw material;

[0035] Dilute citric acid with distilled water to a concentration of 0.1g / ml, add citric acid and ethylene glycol solution (the mol ratio of metal ion and citric acid is 0.3, and the mass ratio of citric acid and ethylene glycol is 1.5) in the mixed raw materials ), and stir evenly to obtain a precursor solution;

[0036] Heat the precursor solution to 75 ° C for 24 hours to remove excess water, cool it to room temperature, and then place it in a mortar for grinding to obtain a precursor powder; then pre-prepared the ground precursor powder at 700 ° C Calcined for 5 h to remove excess organic matter, and then the pre-calcined precursor powder was placed in a muffle furnace for calcination at 1000° C. for 2 h.

[0037] Add 0.1...

Embodiment 3

[0040] Embodiment 3: (Lu 0.98 Tb 0.02 ) 2 o 3 transparent ceramic

[0041] According to (Lu 0.98 Tb 0.02 ) 2 o 3 The stoichiometric ratio of each element in the 3 ) 3 ·6H 2 O and TbCl 3 ·6H 2 O powder as a reaction raw material;

[0042] Dilute citric acid with distilled water to a concentration of 0.2g / ml, add citric acid and ethylene glycol solution (the mol ratio of metal ion and citric acid is 0.5, and the mass ratio of citric acid and ethylene glycol is 2 ), and stir evenly to obtain a precursor solution;

[0043] Heat the precursor solution to 80°C for 24 hours to remove excess water, cool it to room temperature, and then place it in a mortar for grinding to obtain a precursor powder; then pre-grind the precursor powder at 800°C Calcined for 7 hours to remove excess organic matter, and then placed the precalcined precursor powder in a muffle furnace for calcination at 1200°C for 3 hours.

[0044] Add 0.2g / ml of binder polyvinyl alcohol (polymerization degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com