Low-cost beta titanium alloy

A β-titanium alloy, low-cost technology, applied in the field of titanium alloys, can solve the problems of rising costs, restricting promotion and application, etc., and achieve the effect of reducing manufacturing costs and having broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A low-cost β-titanium alloy of the present invention is briefly described in conjunction with specific embodiments.

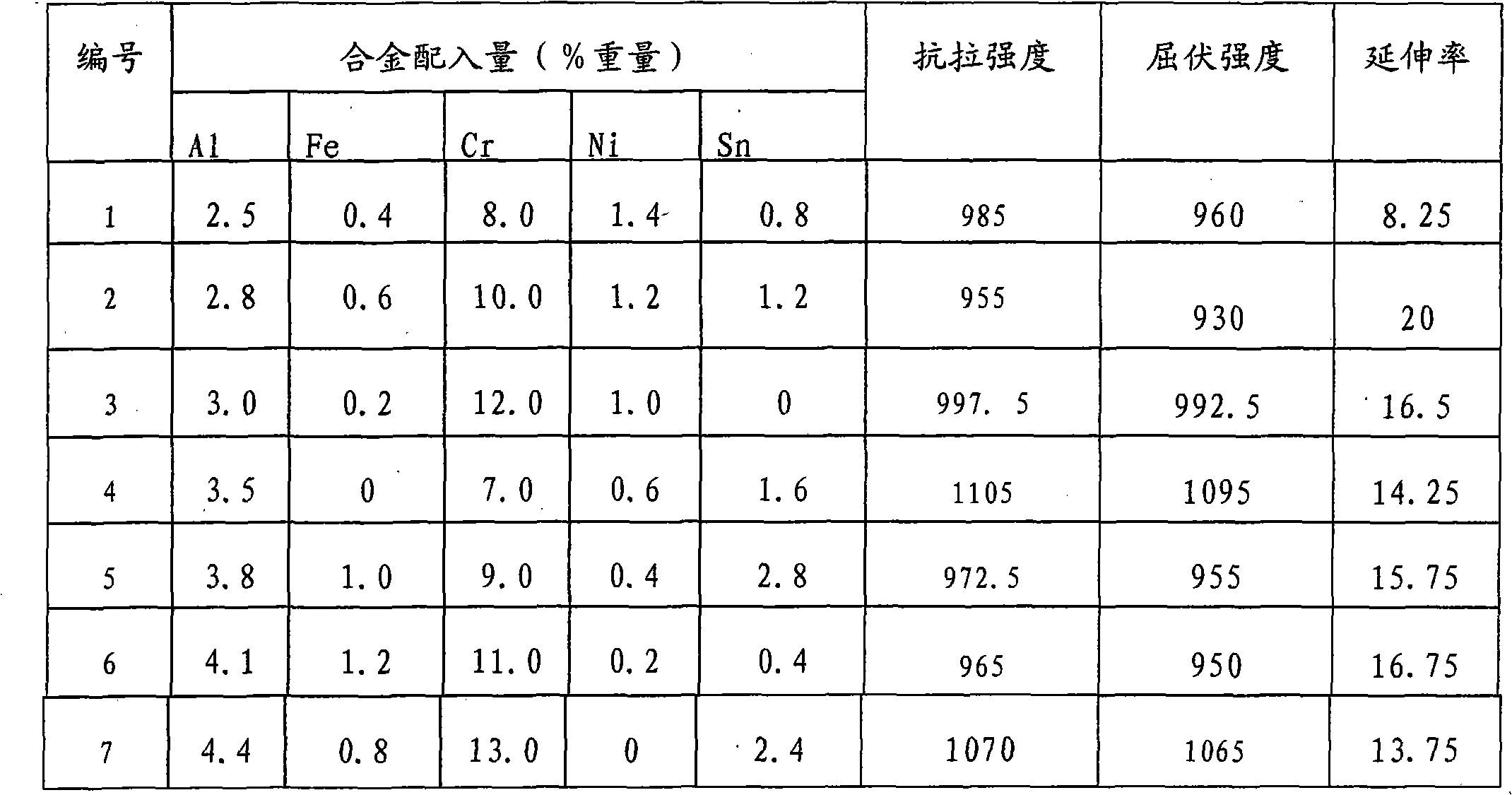

[0010] The low-cost β-titanium alloy of the present invention, the titanium alloy is composed of the following components in weight percent: 1.5-4.5% of aluminum, 7-14% of chromium, 0-1.5% of iron, 0-1.5% of nickel, and 0-3% of tin , and the rest is composed of titanium and unavoidable impurities.

[0011] According to the above ratio, the alloy materials are fully mixed, pressed into consumable electrodes, melted into ingots in a vacuum electric arc furnace, and can be processed into titanium alloy products of various specifications such as rods, plates, pipes, strips, and wires. .

[0012] The titanium alloy of the invention does not contain precious metals such as zirconium, molybdenum, vanadium, etc., thereby reducing the manufacturing cost of the β titanium alloy, and its performance can also meet the needs of different industries for the β titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com