High-heat-conductivity and high-strength Co-Fe-Ni alloy for mold and additive manufacturing method thereof

A technology of co-fe-ni and additive manufacturing, which is applied in the field of high thermal conductivity and high strength Co-Fe-Ni alloys for molds and their additive manufacturing, can solve the problems that the strength and fatigue life cannot meet the needs of molds, and achieve improved Thermal conductivity and service reliability, considerable economic benefits, and the effect of increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

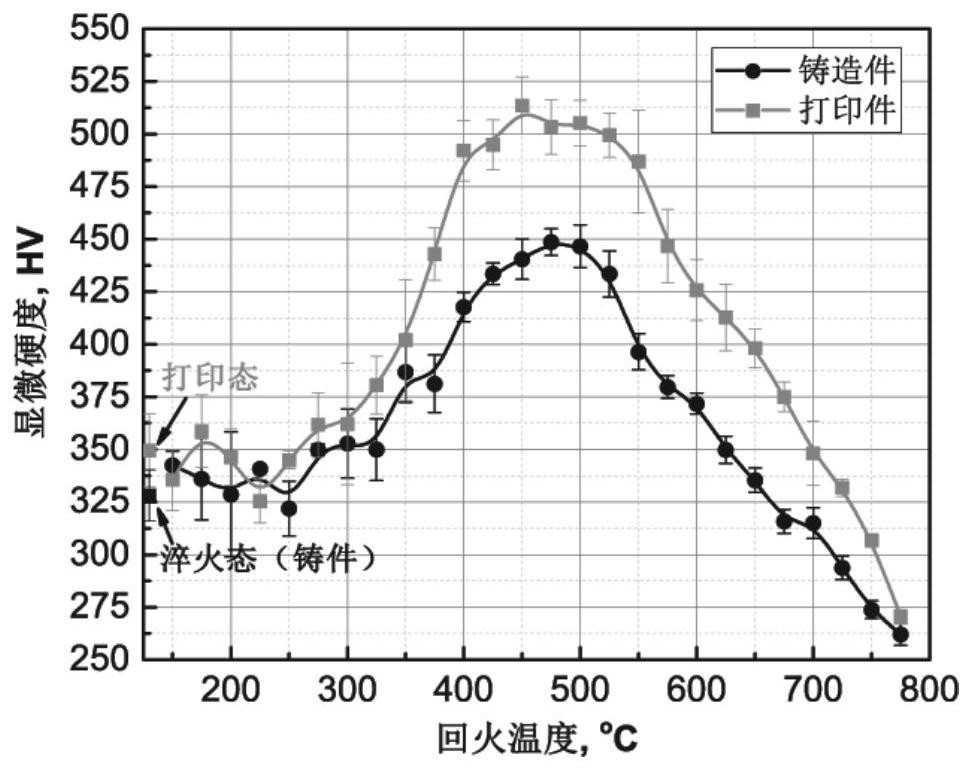

[0041]Composition: Co-40.88Fe-15.94Ni (wt.%)

[0042]Process: powder milling + printing (laser power 130W, scanning rate 0.72m / s, layer thickness 38μm) + 525℃ tempering for 2h.

[0043]Print quality: porosity is 0.19%, density is 99.39%.

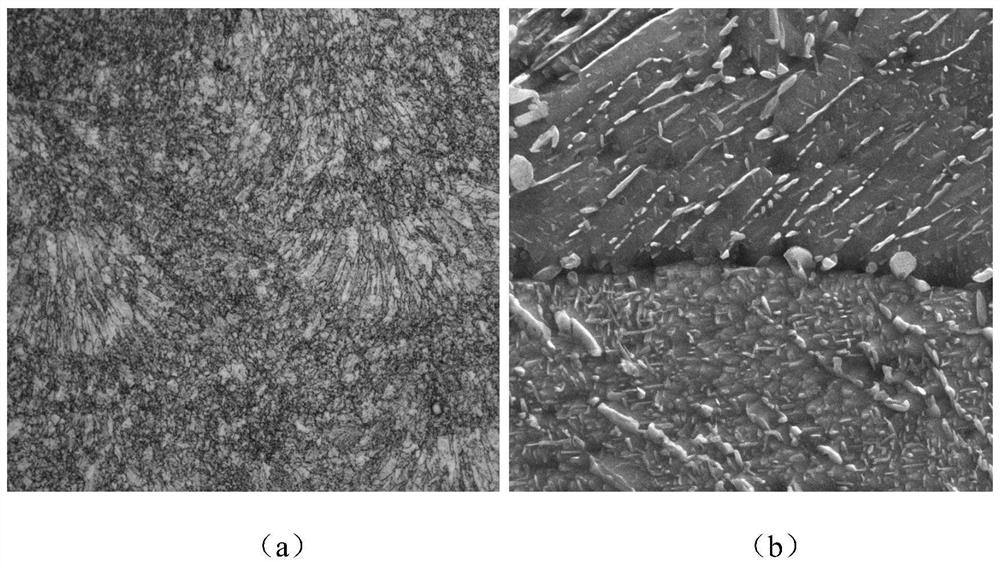

[0044]Microstructure:figure 2 As shown, the layered structure of cellular crystal grains + columnar crystal grains

[0045]Mechanical properties: Yield strength 1210MPa, tensile strength 1420MPa, elongation rate 6.7%, V-notch room temperature impact energy 10.5J.

[0046]specifically:

[0047]In this embodiment:

[0048]The high thermal conductivity and high strength Co-Fe-Ni alloy used for molds has the following chemical composition by weight percentage:

[0049]Fe 40.88%, Ni 15.94%, P<0.015%, S<0.010%, the balance is Co and unavoidable impurities.

[0050]The additive manufacturing method of high thermal conductivity and high strength Co-Fe-Ni alloy for molds includes the following steps:

[0051]S1: According to the above composition ratio, the high-temperature molten allo...

Embodiment 2

[0059]Composition: Co-40.88Fe-15.94Ni (wt.%)

[0060]Process: pulverizing + printing (laser power 130W, scanning rate 0.72m / s, layer thickness 38μm) + 900°C solid solution for 1h-quenching +525°C tempering for 2h.

[0061]Print quality: porosity is 0.19%, density is 99.39%.

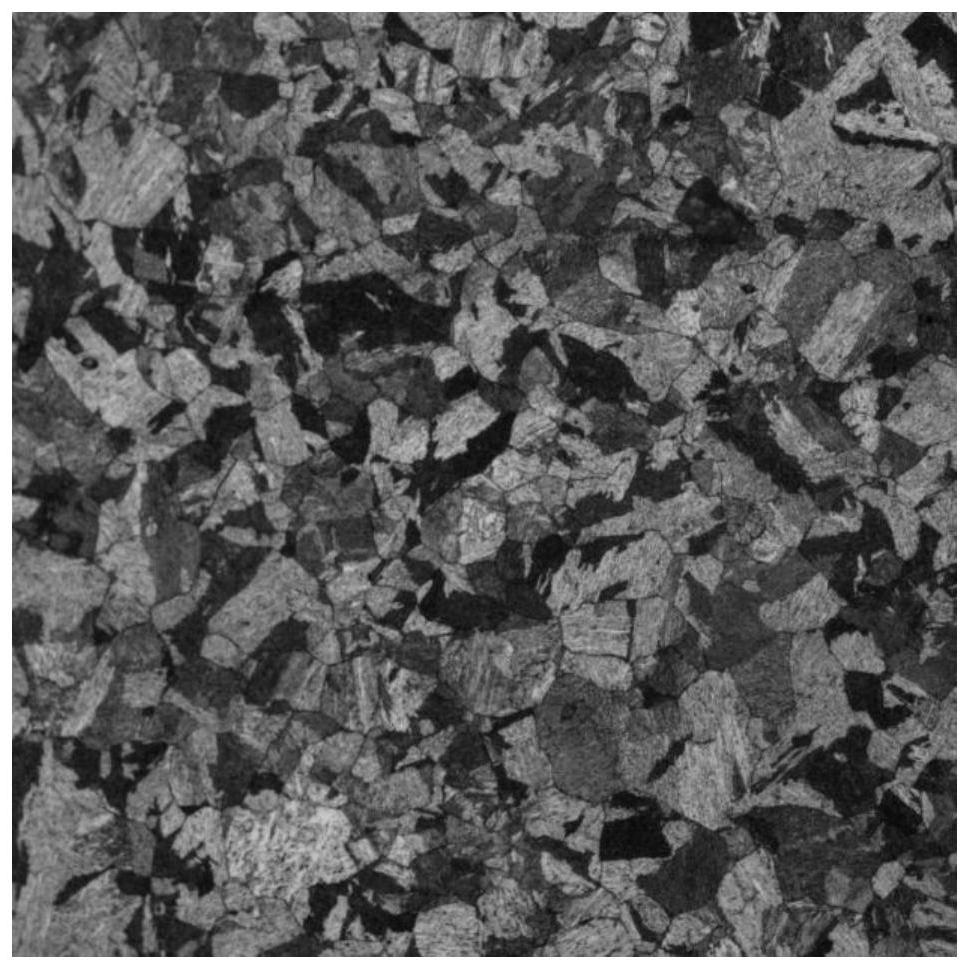

[0062]Microstructure:image 3 Shown, equiaxed grains.

[0063]Mechanical properties: yield strength 1020MPa, tensile strength 1220MPa, elongation 6.2%, V-notch room temperature impact energy 18.3J.

[0064]More specifically:

[0065]The high thermal conductivity and high strength Co-Fe-Ni alloy used for molds has the following chemical composition by weight percentage:

[0066]Fe 40.88%, Ni 15.94%, P<0.015%, S<0.010%, the balance is Co and unavoidable impurities.

[0067]The additive manufacturing method of high thermal conductivity and high strength Co-Fe-Ni alloy for molds includes the following steps:

[0068]S1: According to the above composition ratio, the high-temperature molten alloy is cooled to room temperature by the gas atomiza...

Embodiment 3

[0075]Composition: Co-40.88Fe-15.94Ni (wt.%)

[0076]Process: pulverizing + printing (laser power 130W, scanning rate 0.72m / s, layer thickness 38μm) + 700℃ two-phase zone critical tempering for 1h-quenching +525℃ tempering for 2h.

[0077]Print quality: porosity is 0.19%, density is 99.39%.

[0078]Microstructure:Figure 4 As shown, the cellular crystal grains with dispersed γ phase + the layered structure between columnar crystal grains

[0079]Mechanical properties: yield strength 976MPa, tensile strength 1090MPa, elongation 10.5%, V-notch room temperature impact energy 46.6J.

[0080]More specifically:

[0081]The high thermal conductivity and high strength Co-Fe-Ni alloy used for molds has the following chemical composition by weight percentage:

[0082]Fe 40.88%, Ni 15.94%, P<0.015%, S<0.010%, the balance is Co and unavoidable impurities.

[0083]The additive manufacturing method of high thermal conductivity and high strength Co-Fe-Ni alloy for molds includes the following steps:

[0084]S1: According to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com