A kind of preparation method of composite core for optical fiber insulator

A composite core and insulator technology, applied in the direction of insulators, optics, light guides, etc., can solve problems such as insulation sealing failure, optical fiber brittleness, and optical fiber cladding peeling off, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

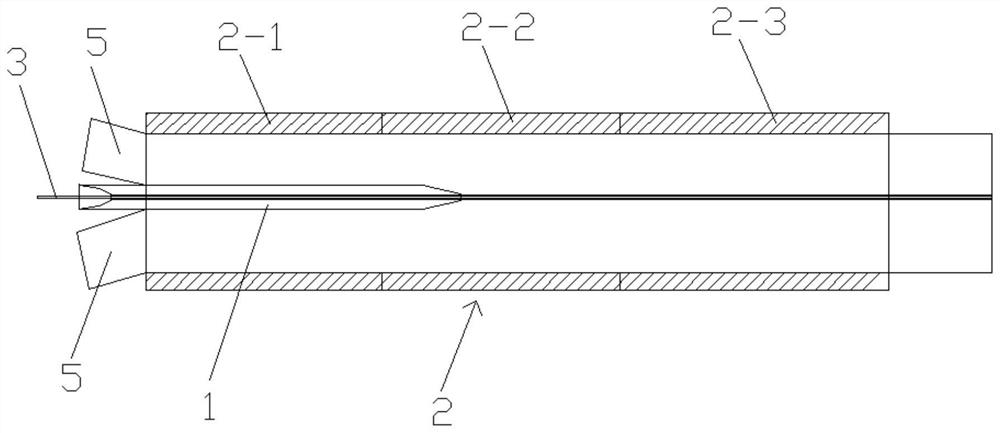

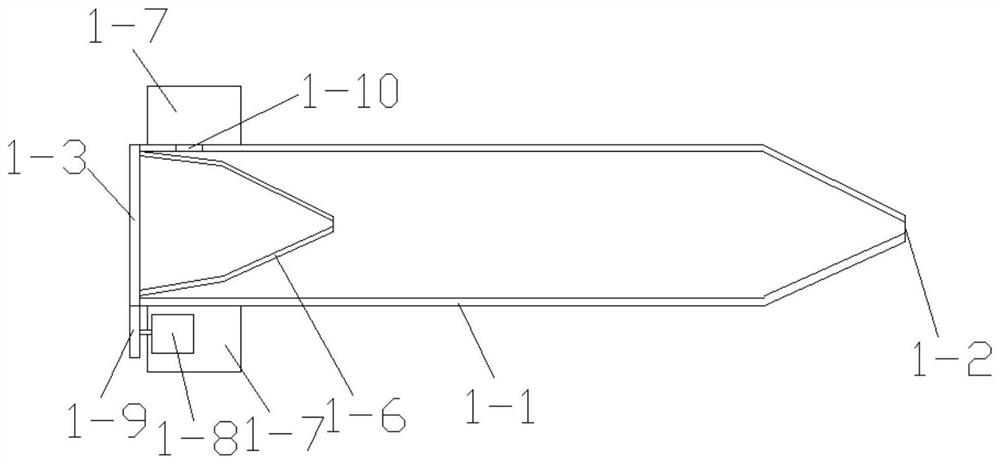

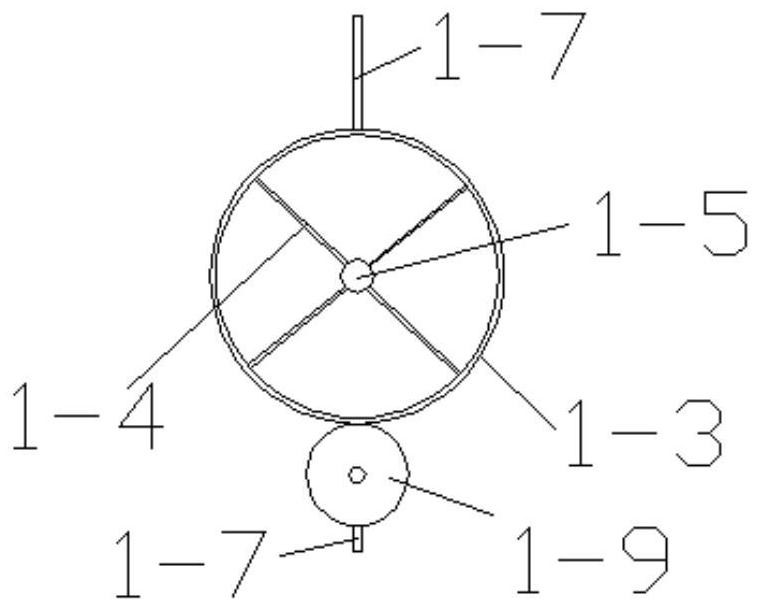

[0035] Step 1. Fix the optical fiber isolation and protection tooling 1 in the pultrusion core mold 2 through the mounting frame 1-7 to obtain a processing device; the length of the pultrusion core mold 2 is 900 mm, and the inner diameter is 50 mm; the optical fiber isolation The length of the protective tooling 1 is 2 / 3 of the length of the pultrusion core mold 2, the diameter of the outlet hole 1-2 is 3mm; the temperature of the preheating zone 2-1 is 90°C-95°C, the The temperature of the forming zone 2-2 is 120°C-127°C, the temperature of the curing zone 2-3 is 155°C-157°C; 2 The distance from the right end face is 1 / 2 of the length of the pultrusion core die 2;

[0036] Step 2: Insert the optical fiber 3 through the optical fiber inlet hole 1-5 in the processing device obtained in step 1 and pass through the outlet hole 1-2 and then pass through the pultrusion core mold 2, and then remove the optical fiber protective ...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1. Fix the optical fiber isolation and protection tooling 1 in the pultrusion core mold 2 through the mounting frame 1-7 to obtain a processing device; the length of the pultrusion core mold 2 is 900 mm, and the inner diameter is 35 mm; the optical fiber isolation The length of the protective tooling 1 is 3 / 4 of the length of the pultrusion core mold 2, and the diameter of the outlet hole 1-2 is 5mm; the pultrusion core mold 2 is the preheating zone 2 from left to right -1. Forming zone 2-2 and curing zone 2-3, the temperature of the preheating zone 2-1 is 95°C-103°C, the temperature of the forming zone 2-2 is 127°C-131°C, the The temperature of the curing zone 2-3 is 157°C-159°C; the optical fiber isolation and protection tooling 1 is inserted from the left side of the pultrusion core mold 2, and the outlet hole 1-2 of the optical fiber isolation and protection tooling 1 is drawn The distance from the right e...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1. Fix the optical fiber isolation and protection tooling 1 in the pultruded core mold 2 through the mounting frame 1-7 to obtain a processing device; the length of the pultruded core mold 2 is 1200mm, and the inner diameter is 70mm; the optical fiber isolation The length of the protective tooling 1 is 17 / 24 of the length of the pultrusion core mold 2, and the diameter of the outlet hole 1-2 is 6mm; the pultrusion core mold 2 is the preheating zone 2 from left to right -1. Forming zone 2-2 and curing zone 2-3, the temperature of the preheating zone 2-1 is 103°C-105°C, the temperature of the forming zone 2-2 is 131°C-135°C, the The temperature of the curing zone 2-3 is 159°C-165°C; the optical fiber isolation and protection tooling 1 is inserted from the left side of the pultrusion core mold 2, and the outlet hole 1-2 of the optical fiber isolation and protection tooling 1 is drawn The distance from the right e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com