welding equipment

A welding equipment and arc welding technology are applied in the welding field of seat metal frame to achieve the effects of good driving stability, low welding labor intensity and accurate welding position welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

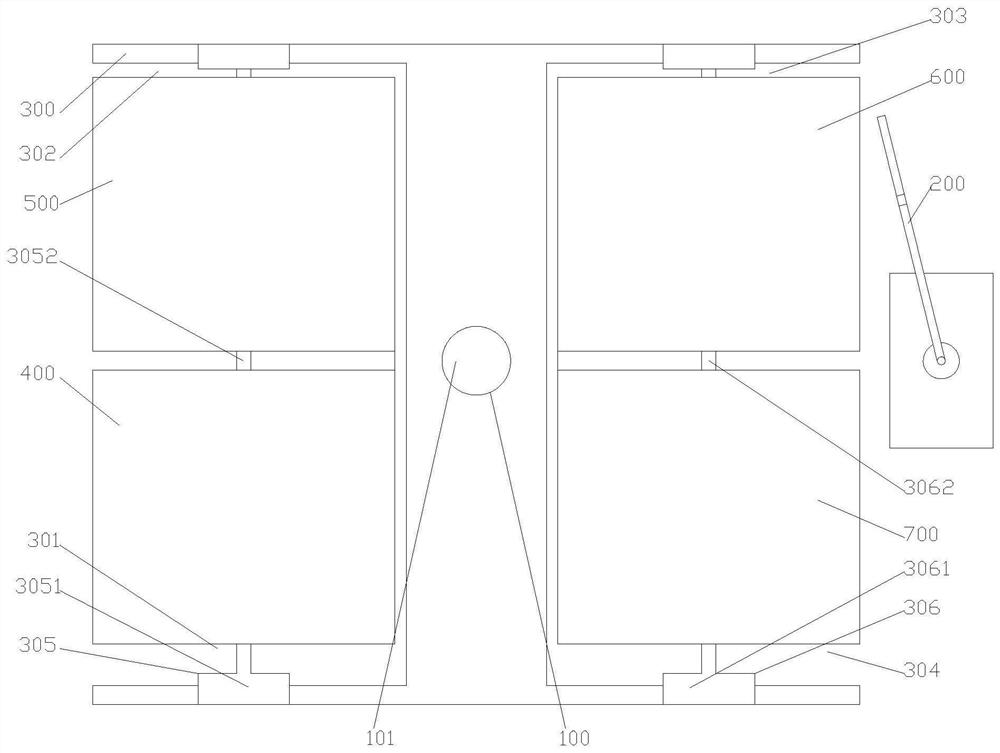

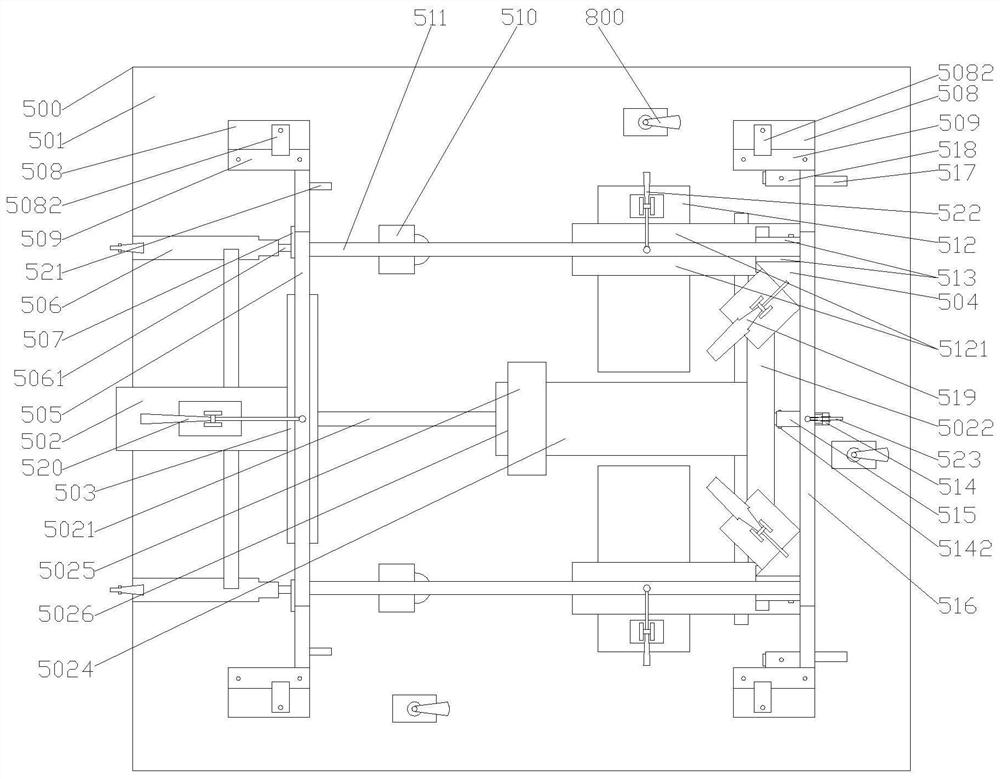

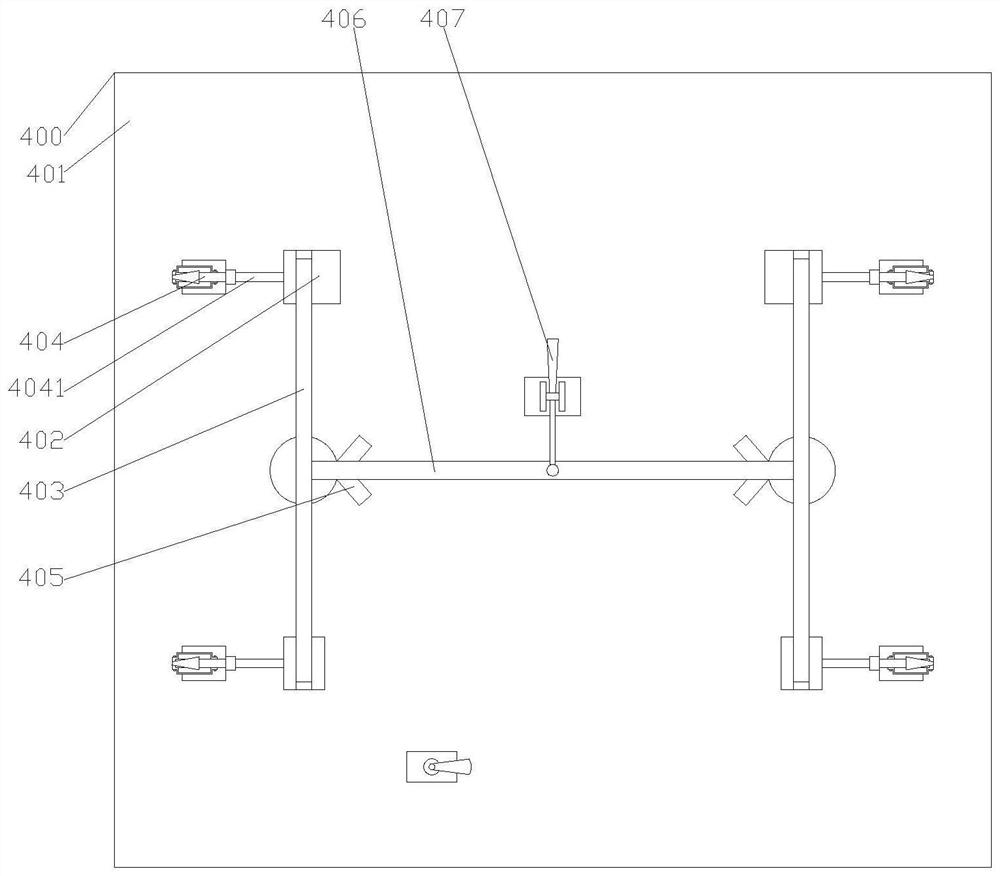

[0040] Such as figure 1 The welding equipment shown includes a first driving device 100 and an arc welding robot arm 200. The driving end of the first driving device is provided with a mounting frame 300, and the mounting frame is provided with a first station 301, a second station 302, a Three stations 303 and the fourth station 304, the first station, the second station, the third station and the fourth station are distributed in a rectangle on the mounting frame, the first station, the second station, the third station The station and the fourth station are equipped with such image 3 and Figure 7 The shown seat I-frame fixing device 400, such as figure 2 and Figure 6 The seat frame fixing device 500 shown, such as Figure 4 and Figure 8 The seat drive tube frame fixture 600 shown and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com