Construction method of cable-net structure with double inclined arch bearing hyperbolic parabola with limited construction space

A hyperbolic paraboloid and cable-net structure technology, applied in special structures, building components, etc., can solve problems such as unfavorable cross-construction, affecting construction period, and occupying large space, so as to reduce erection workload, improve construction efficiency, avoid The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

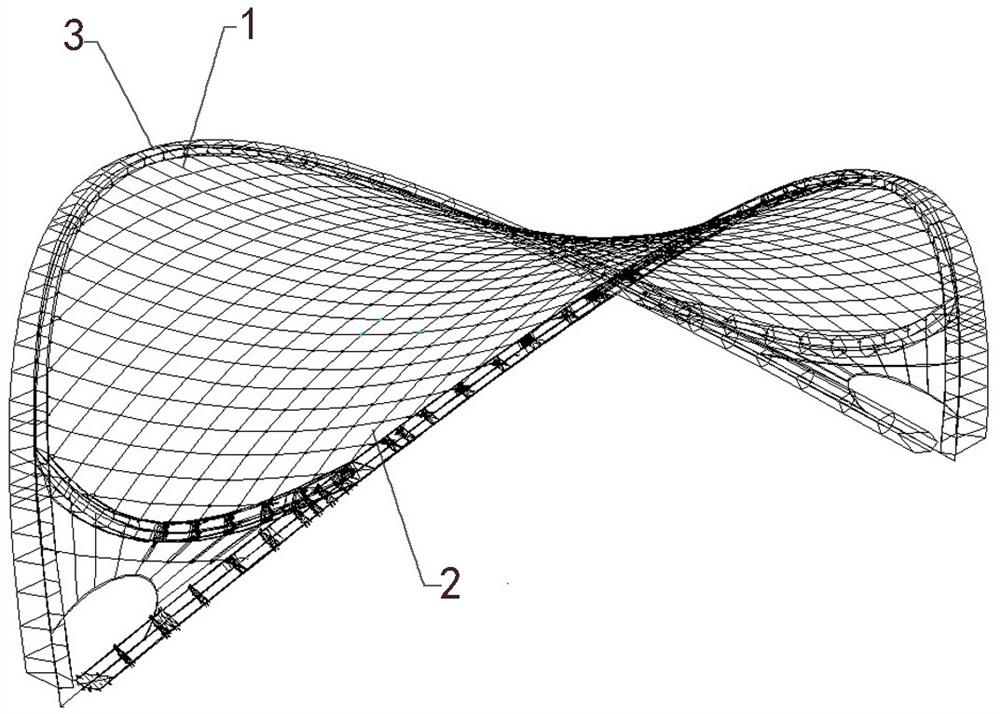

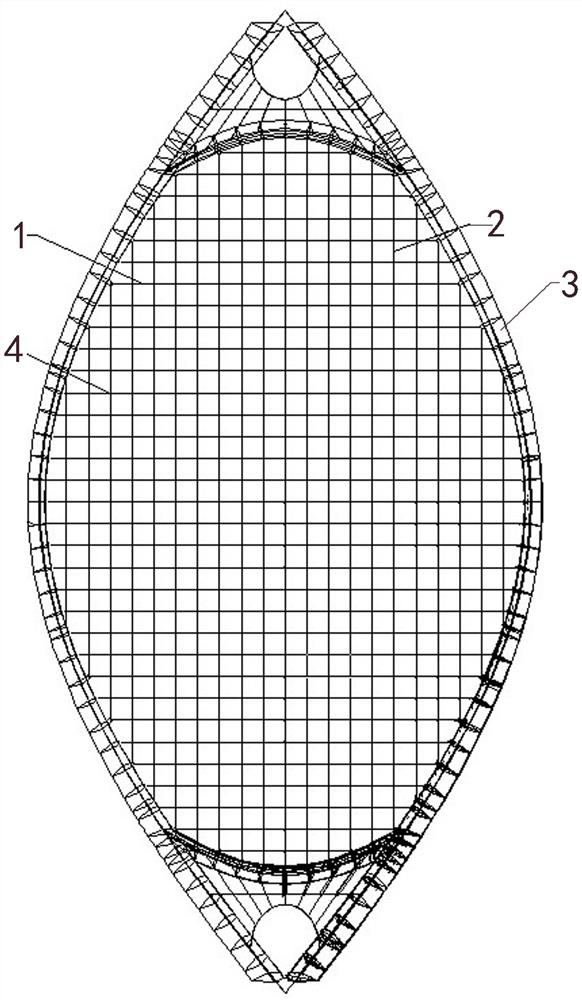

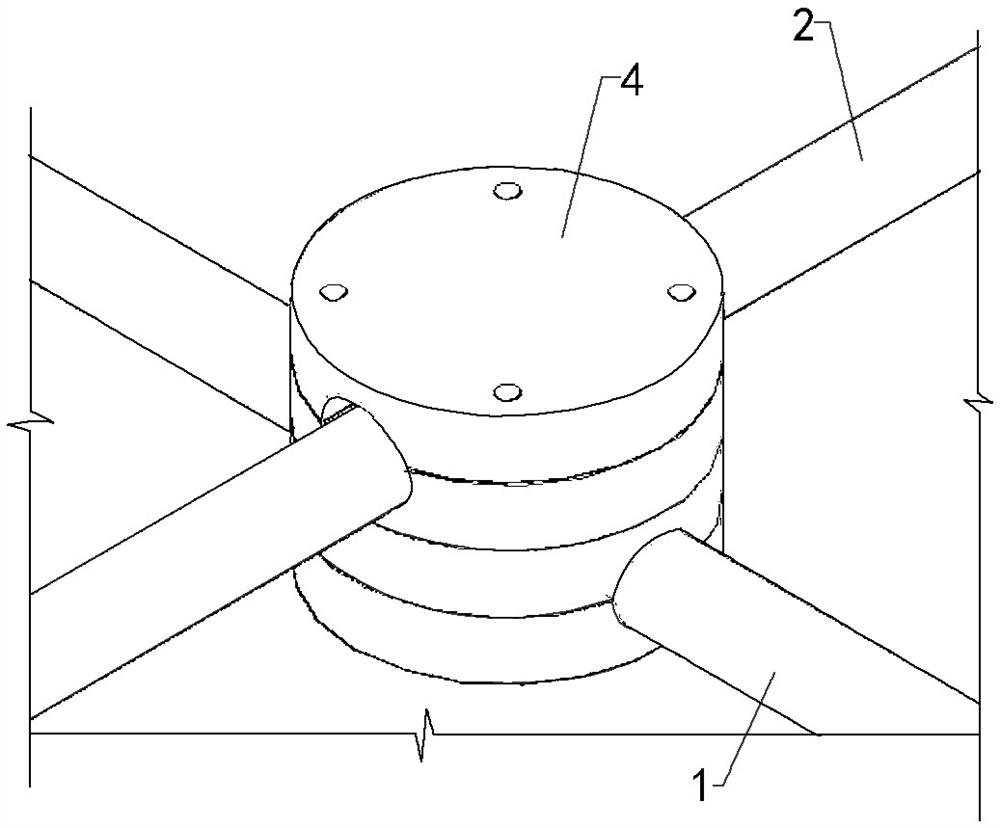

[0053] Such as Figure 1 to Figure 3 As shown, the cable net structure of the double-slanted arch bearing hyperbolic paraboloid with limited construction space in the present invention is in the shape of a saddle, including the load-bearing cables 1 of the lower layer, the wind-resistant cables 2 of the upper layer and the edge members around the cable net. The load-bearing cables 1 and The wind-resistant cable 2 is connected and fixed by the cable clamp 4; the edge member is the arch beam 3, and the arch beam 3 is a floor-standing double-slope arch beam 3, and the cable head screws at the two ends of the load-bearing cable 1 and the wind-resistant cable 2 are respectively connected to the top of the arch beam 3. The connecting ear plates are pinned, and there is an obstacle 5 on one side of the construction site under the cable net structure, which is the side A with limited space, and the opposite side is side B with no space limitation.

[0054] This embodiment takes the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com