A heavy-duty full hall formwork support system

A formwork and system technology, applied in the direction of building structure support, building structure support, scaffolding connection, etc., can solve the problems of erection defects, difficulty in controlling the torque and quality of fasteners, and reduce structural bearing capacity, so as to reduce the workload of erection, Improve overall stability and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

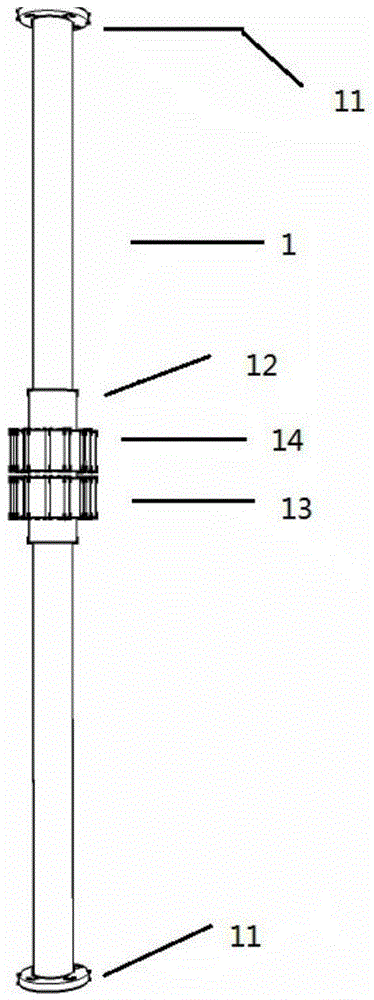

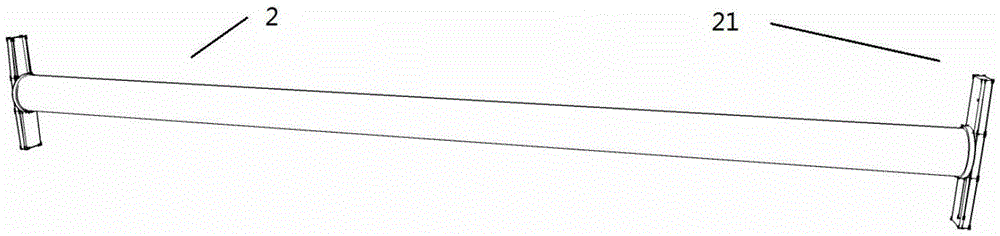

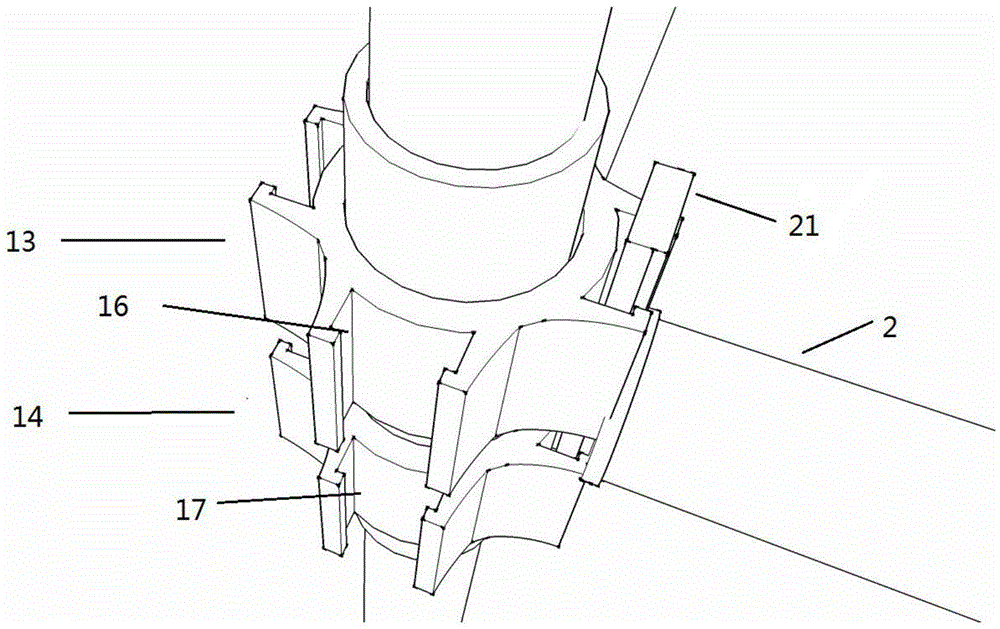

[0026] Components such as vertical rods, horizontal rods, adjustable jacking brackets and adjustable bases in the present invention are all produced in batches in factories. The steel pipes used in the present invention are mainly straight seam electric welded steel pipes or steel pipes, the material is Q235 steel, and the steel pipe specification is P48.3×3.6; the casing specification at the node of the vertical pole is P58.3×5; and slide slots are made of steel castings.

[0027] The manufacturing process of the slot is completed in the factory. The mold is made according to the designed slot size and shape, the metal is melted, the mold is poured and the component is cast, and finally the slot is processed to complete.

[0028] When the project is processing the pole, first process the circular end plate at the end of the pole. The thickness of the end plate is 10mm, the diameter is 80mm, and 4 bolt holes with a diameter of 10mm are evenly set at 15mm from the edge; then P4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com