Preparation method of olefin-olefin alcohol copolymer

A technology for copolymers and olefin alcohols, which is applied in the field of preparation of copolymers and can solve the problems of solvent removal for polymer transport, difficulty in granulation, scaling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

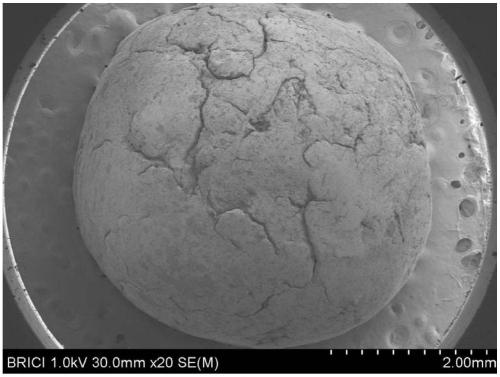

Image

Examples

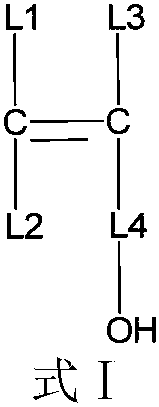

Embodiment 1

[0063] The 1L stainless steel polymerization kettle equipped with mechanical stirring was continuously dried at 130° C. for 6 h, vacuumed while hot and replaced with nitrogen three times. Inject 500 mL of hexane into the polymerization system, and simultaneously add 13.2 mg (20 μmol) of complex 1 shown in formula (1), 5.1 mL (30 mmol) of 2-methyl-2-hydroxyl-7-octene, 30 mL of AlEt 3 (1.0 mol / L hexane solution), at 25° C., maintaining 10 atm of ethylene pressure, and stirring for 30 min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and the performance parameters of the polymer are shown in Table 1.

[0064]

Embodiment 2

[0066] The 1L stainless steel polymerization kettle equipped with mechanical stirring was continuously dried at 130° C. for 6 h, vacuumed while hot and replaced with nitrogen three times. Inject 500 mL of hexane into the polymerization system, and simultaneously add 13.2 mg (20 μmol) of complex 1 shown in formula (1), 5.1 mL (30 mmol) of 2-methyl-2-hydroxyl-7-octene, 30 mL of AlEt 3 (1.0 mol / L hexane solution), 0.5 mL diethylzinc (1 mol / L hexane solution), at 25°C, keep the ethylene pressure of 10 atm, and stir for 30 min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and the performance parameters of the polymer are shown in Table 1.

Embodiment 3

[0068] The 1L stainless steel polymerization kettle equipped with mechanical stirring was continuously dried at 130° C. for 6 h, vacuumed while hot and replaced with nitrogen three times. Inject 500 mL of hexane into the polymerization system, and simultaneously add 13.2 mg (20 μmol) of complex 1 shown in formula (1), 5.1 mL (30 mmol) of 2-methyl-2-hydroxyl-7-octene, 30 mL of AlEt 3 (1.0 mol / L hexane solution), at 80° C., maintaining 10 atm of ethylene pressure, and stirring for 30 min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and the performance parameters of the polymer are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com