A kind of preparation method of olefin-olefin alcohol copolymer

A technology for copolymers and olefin alcohols, which is applied in the field of preparation of olefin-olefin alcohol copolymers, can solve the problems of scaling, polymer transport solvent removal, difficulty in granulation, etc., and achieves less scaling, convenient transportation and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

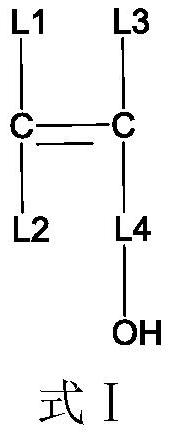

[0097] 1) Preparation of ligand:

[0098] ɑ-diimine compound A1 4.42g (8mmol), then add 50ml tetrahydrofuran, lithium aluminum tetrahydride 0.61g (16mmol), and stir at 60°C for 6 hours. After cooling, the reaction was terminated with aqueous sodium hydroxide solution, and the organic phase was extracted with ethyl acetate, dried, filtered, and recrystallized to obtain colorless crystals as ligand L1 with a yield of 63%. 1 HNMR (CDCl 3 , 300MHz) 7.02-7.23(m,14H),4.03(s,2H,NH),3.75(m,2H),3.04(m,2H),2.88(m,4H,CH(CH 3 ) 2 ),1.19(d,24H,CH 3 ).

[0099] 2) Preparation of complex 1: 10ml (DME) NiBr 2 (277mg, 0.9mmol) in dichloromethane solution was added dropwise to 10ml of ligand L1 (501mg, 0.9mmol) in dichloromethane solution, stirred at room temperature for 6 hours, a precipitate precipitated, filtered, washed with ether, and dried to obtain a red powder solid. The yield was 80%. Elemental analysis (C 40 h 48 Br 2 N 2 Ni): C, 61.97; H, 6.24; N, 3.61; found (%): C, 62.25...

Embodiment 2

[0102] Dry the 1L stainless steel polymerization kettle equipped with mechanical stirring at 130 ° C for 6 hours, vacuumize while it is hot and use N 2 Air replacement 3 times. Inject 500 mL of hexane into the polymerization system, and simultaneously add 7.8 mg (10 μmol) of complex 1, 30 mmol (5.1 mL) of 2-methyl-2-hydroxyl-7-octene, 30 mL of AlEt 3 (1.0mol / L hexane solution), 6.5mL MAO (1.53mol / L toluene solution), at 20°C, keep ethylene pressure of 10atm, and stir for 30min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and the performance parameters of the polymer are shown in Table 1.

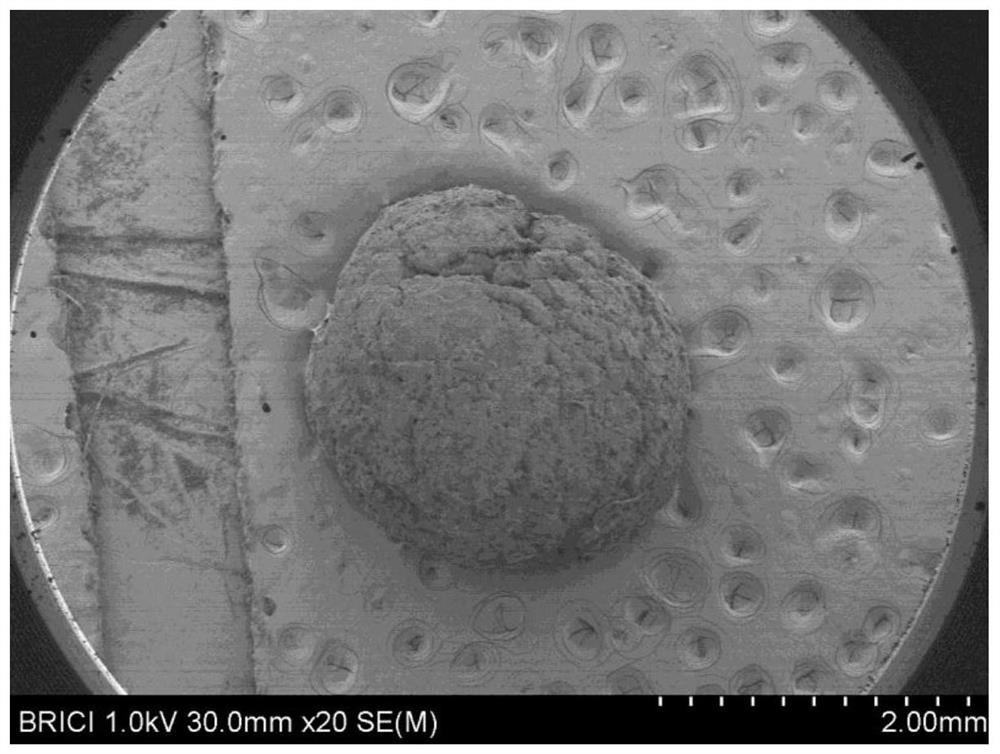

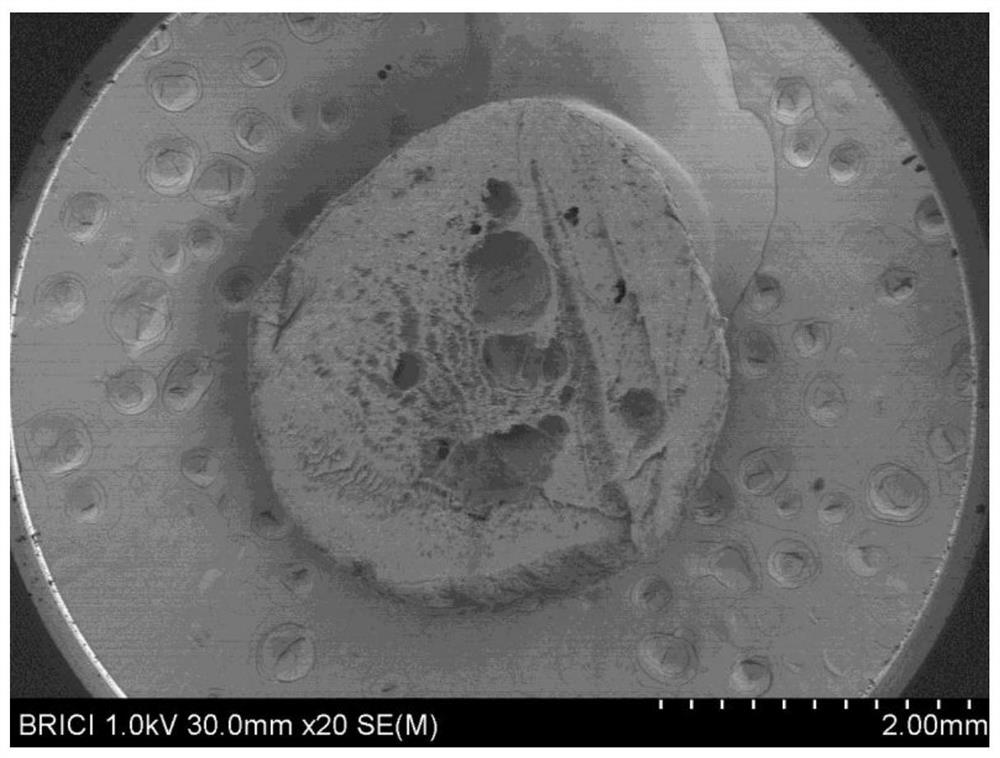

[0103] Figure 1-Figure 2 The obtained copolymer and the cross-sectional view of the copolymer are shown, and it can be seen that the obtained spherical polymer has a cavity inside.

Embodiment 3

[0105] Dry the 1L stainless steel polymerization kettle equipped with mechanical stirring at 130 ° C for 6 hours, vacuumize while it is hot and use N 2 Air replacement 3 times. Inject 500 mL of hexane into the polymerization system, and simultaneously add 7.8 mg (10 μmol) of complex 1, 30 mmol (5.1 mL) of 2-methyl-2-hydroxyl-7-octene, 30 mL of AlEt 3 (1.0mol / L hexane solution), 6.5mL MAO (1.53mol / L toluene solution), at 60°C, keep 10atm ethylene pressure, and stir for 30min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and the performance parameters of the polymer are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com