Burner fire cover for gas stove and burner with same

A gas cooker and burner technology, which is applied in gas fuel burners, burners, and non-flammable liquid/gas transportation, etc., can solve the problems of uneven heating of the bottom of the pot, unfavorable cleaning of the stove, and blackening of the bottom of the center pot. Achieve the effect of improving the success rate of ignition, improving the success rate of fire retention, and slowing down the intake speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

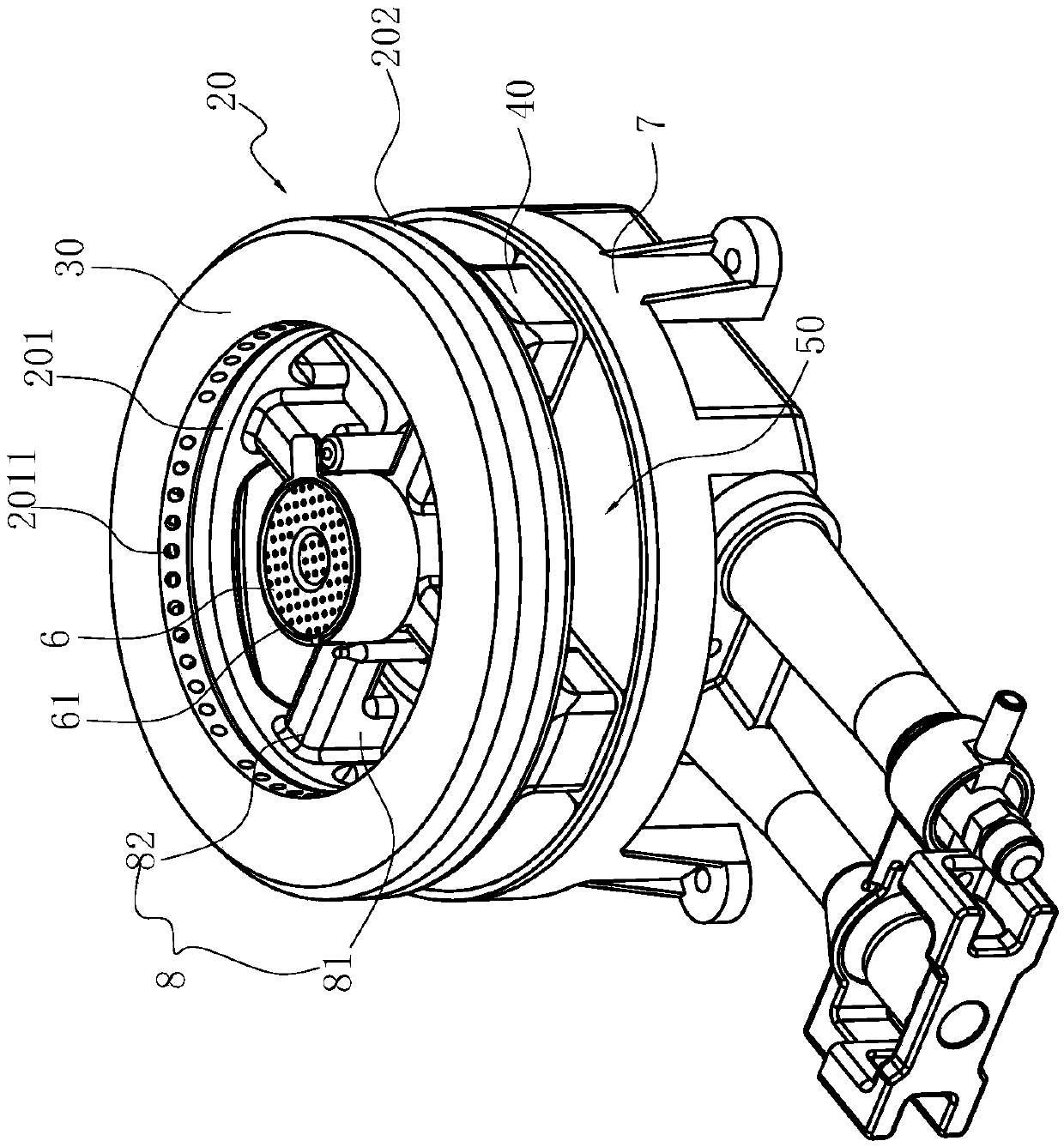

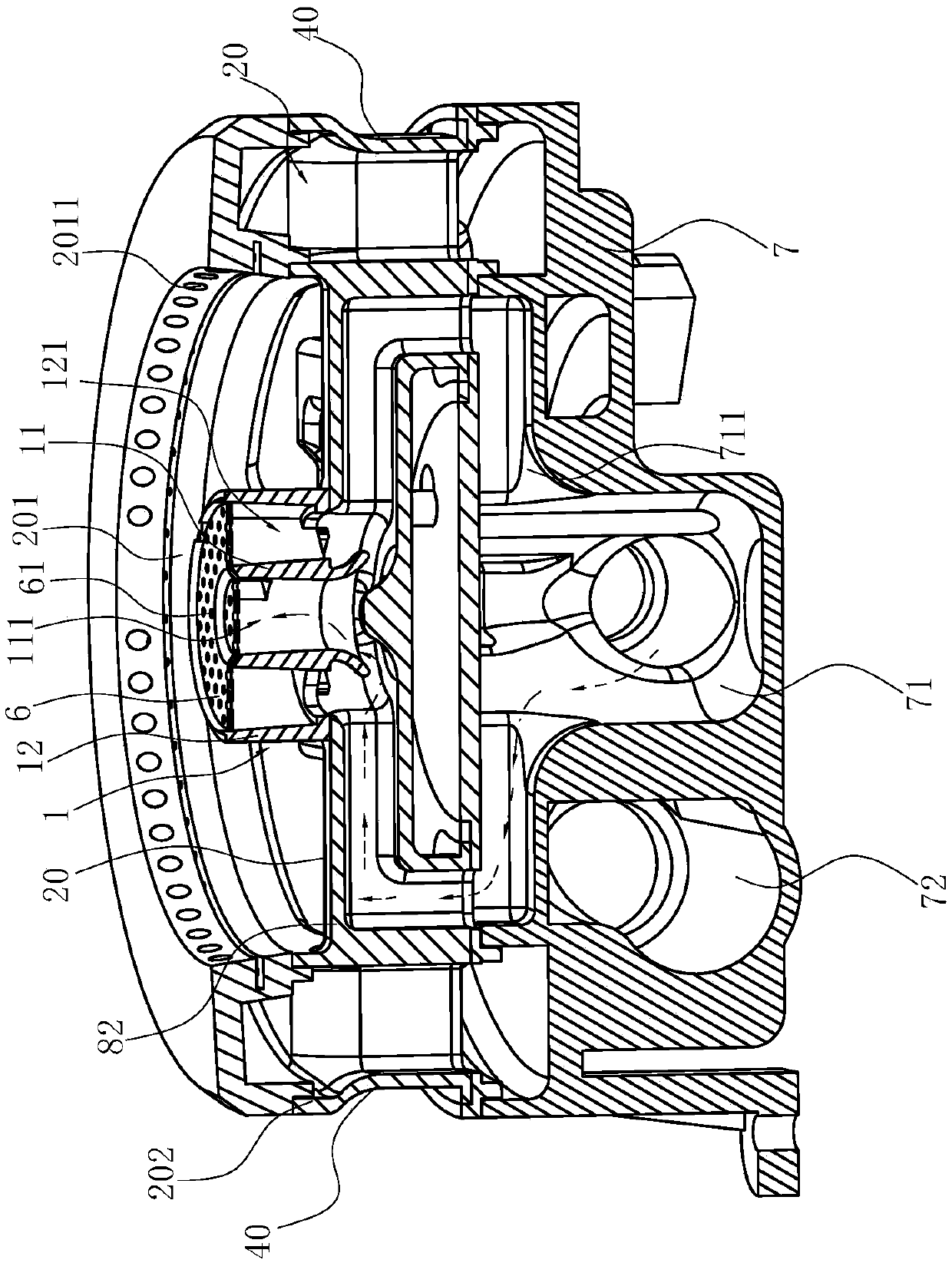

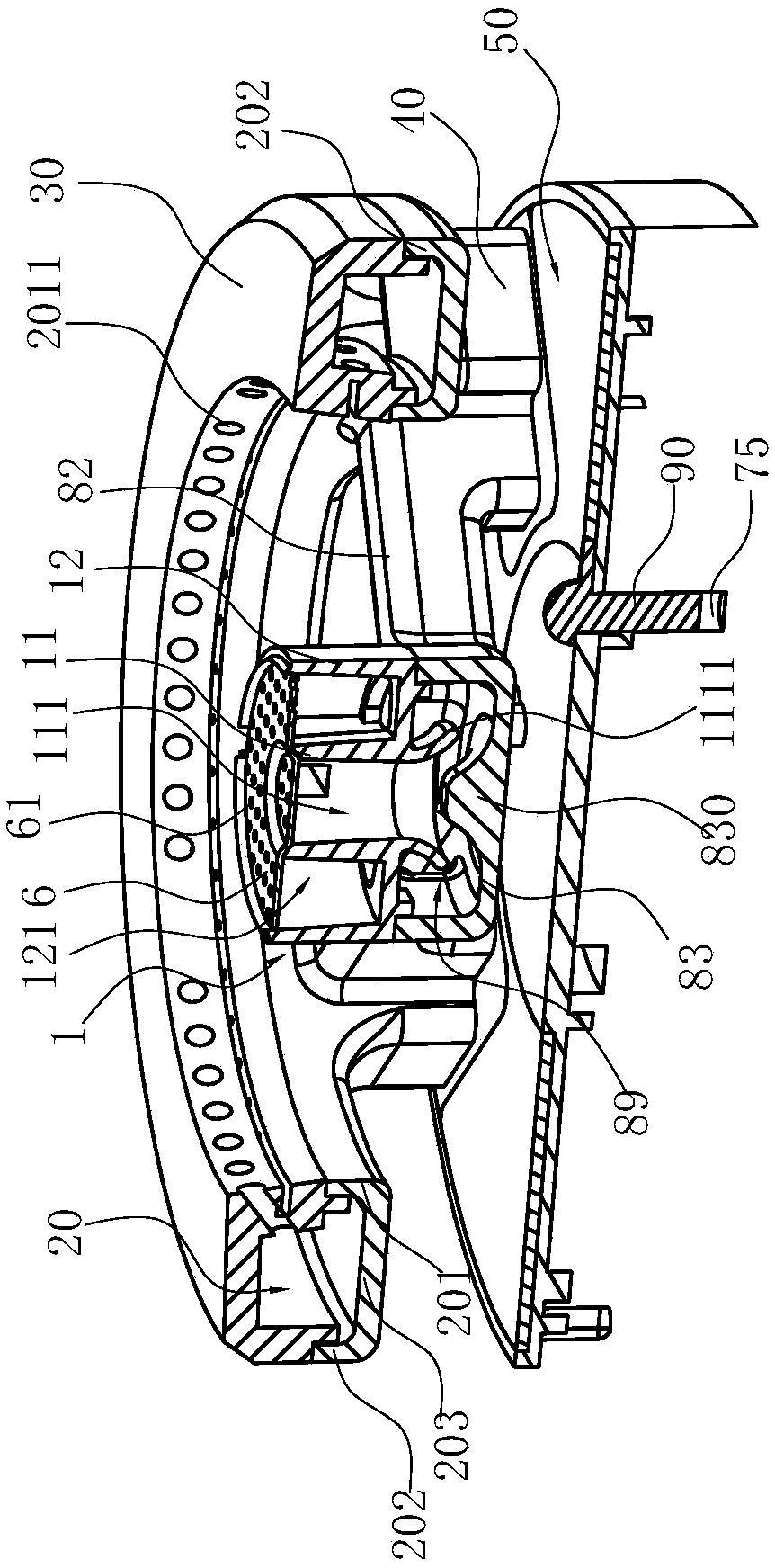

[0039] Such as Figure 1-8 Shown is the best embodiment of the present invention. In this embodiment, the burner fire cover for the gas cooker includes an inner ring fire cover 1, and the inner ring fire cover 1 includes an inner ring wall 11 and an outer ring wall 12 arranged at intervals inside and outside, and the inner ring wall 11 is surrounded by a central The cavity 111, the inner ring wall 11 and the outer ring wall 12 together form a peripheral cavity 121, the outer peripheral cavity 121 has a diversion channel 3 for diverting gas, and the gas inlet 31 of the diversion channel 3 is opened inside On the ring wall 11 and communicated with the central cavity 111 , the gas outlet 32 of the guide channel 3 is opened on the outer ring wall 12 . Through the conduction channel 3, the four thermocouples have relatively independent "fire-pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap