Thread collection device

A silk and container technology, applied in the field of silk picking devices, can solve problems such as difficulties and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

[0108] (Purpose)

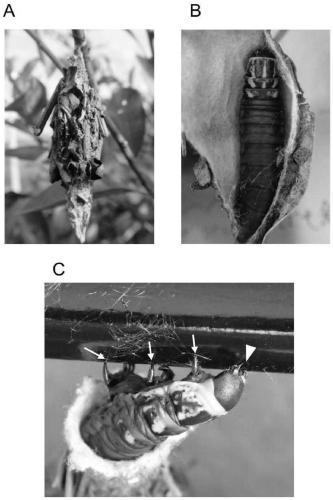

[0109] It was verified that using the silk picking device of the present invention, it is possible to easily and simply collect a block of silk that does not contain impurities and is composed of pure bag moth larvae silk.

[0110] (method)

[0111] As the bag moth larvae, the last instar larvae of the bag moth collected in the field in November were used. The maximum body width of each individual is in the range of 9.0 mm to 10.0 mm, and the total length is in the range of 30.0 mm to 32.0 mm.

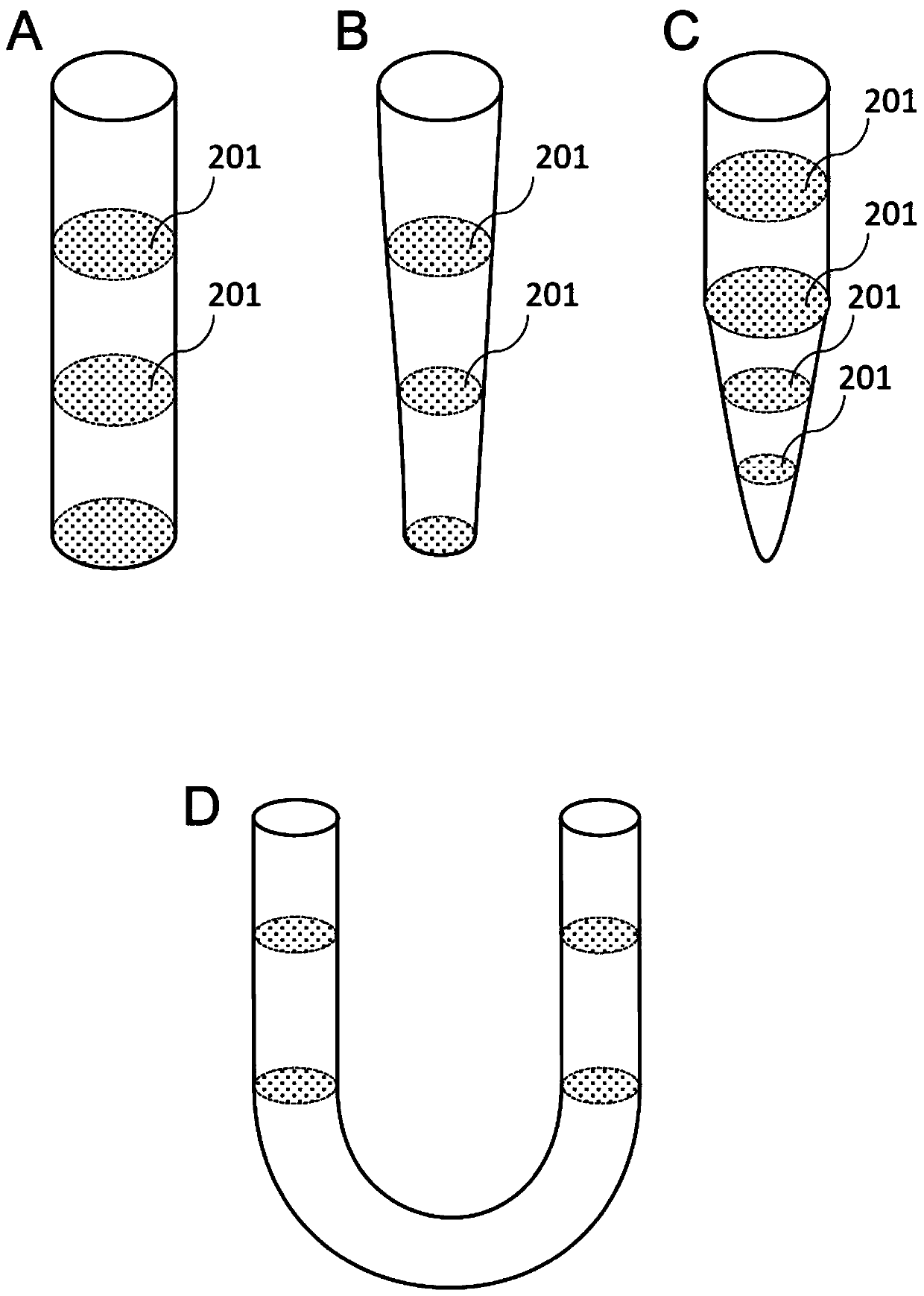

[0112] A 10 mL polypropylene conical tube (Iwaki Corporation) was used as the container of the silk picking device. The width (inner diameter) of the maximum short-axis section of the internal space of this container was 14.5 mm, and the length was 97.0 mm. In this case, the tube opening corresponds to the container access hole. In addition, a test tube rack was used as the fixing part.

[0113] After the bag moth larvae were taken out from the nest u...

Embodiment 2

[0116]

[0117] (Purpose)

[0118] It was verified that the silk picking device of the present invention equipped with a discharge hole can collect a block of silk silk without impurities from an active bag moth larvae.

[0119] (method and results)

[0120] As the bag moth larvae, 10 sub-to-last instar larvae of the tea bag moth collected in the field in June were used. The maximum body width of each individual ranged from 6.0 mm to 8.0 mm, and the total length ranged from 24.0 mm to 30.0 mm.

[0121] A polypropylene 10 mL pipette tip (Pipette tip, Eppendorf) was used as the container of the silk picking device for verification. The width (diameter) of the maximum short-axis cross-section of the inner space of this container was 13.5 mm. Furthermore, in the case of a pipette tip, the pipette connection port corresponds to the container access hole. On the other hand, the bottom of the tube (tip tip) was cut to create a discharge hole with a diameter of 3.5 mm. A 10-mL ...

Embodiment 3

[0123]

[0124] (Purpose)

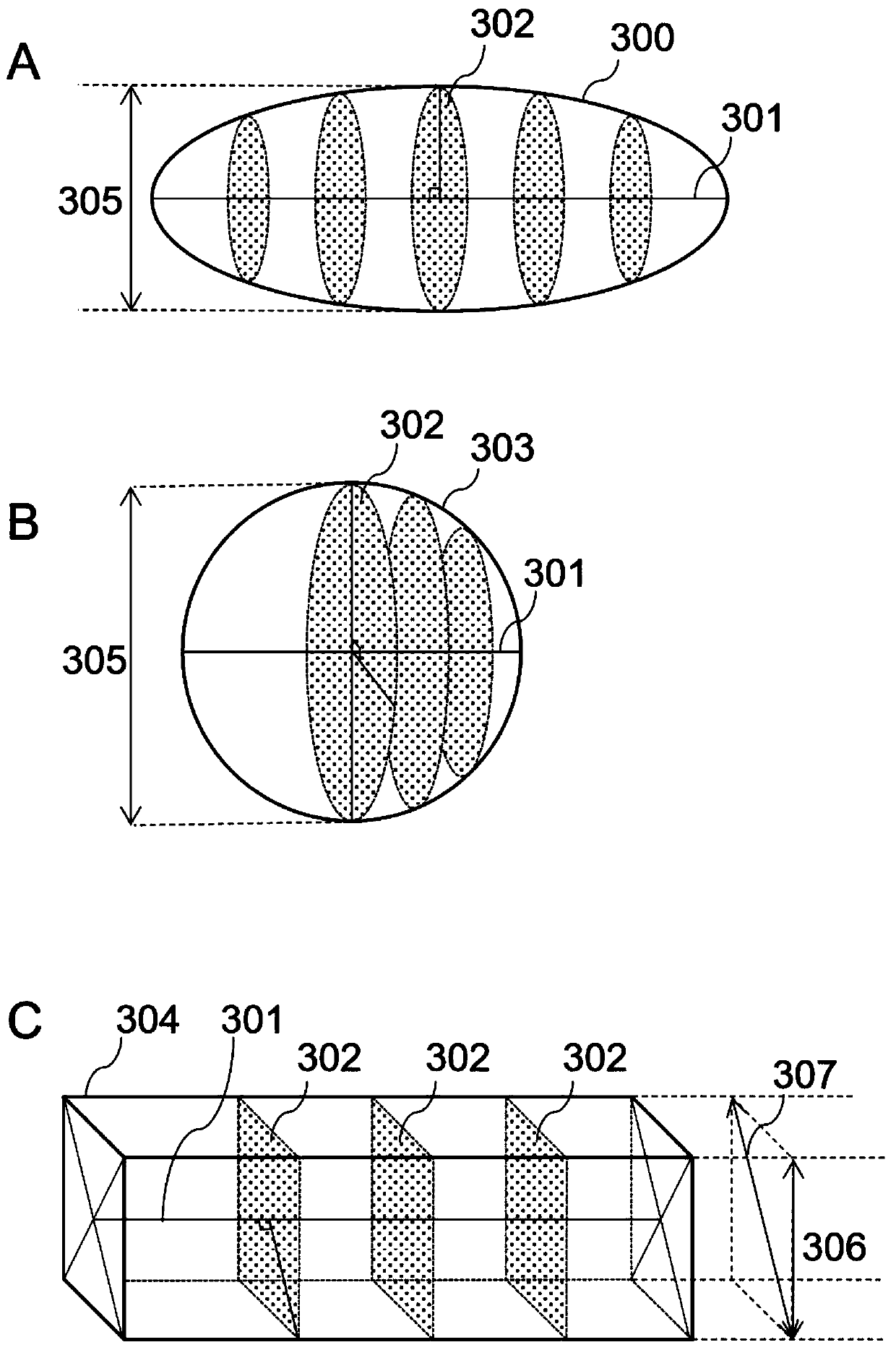

[0125] The relationship between the ratio of the maximum short-axis cross-section width of the container inner space of the silk picking device to the maximum body width of the housed bag moth larvae and the formation of silk lumps was verified.

[0126] (method)

[0127] As the bag moth larvae, the last instar larvae of tea bag moth larvae collected in the field in June with a total length of 30 mm and a maximum body width of 7 mm were used.

[0128] The width (diameter) of the largest short-axis section of the inner space of the container in the silk picking device is 9 mm (2.5 mL pipette tip made of polypropylene, φ9 mm × height 115 mm: Eppendolf), 12.0 mm (6 mL glass test tube, φ12mm × height 75mm: As one), 15.0mm (15mL glass test tube, φ15mm × height 85mm: As one), 22.0mm (50mL glass test tube, φ22mm × height 200mm: As one), 30.0mm (50mL Conical tube made of polypropylene, φ30mm x height 118mm: As one company), 120mm (cylindrical plastic co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com