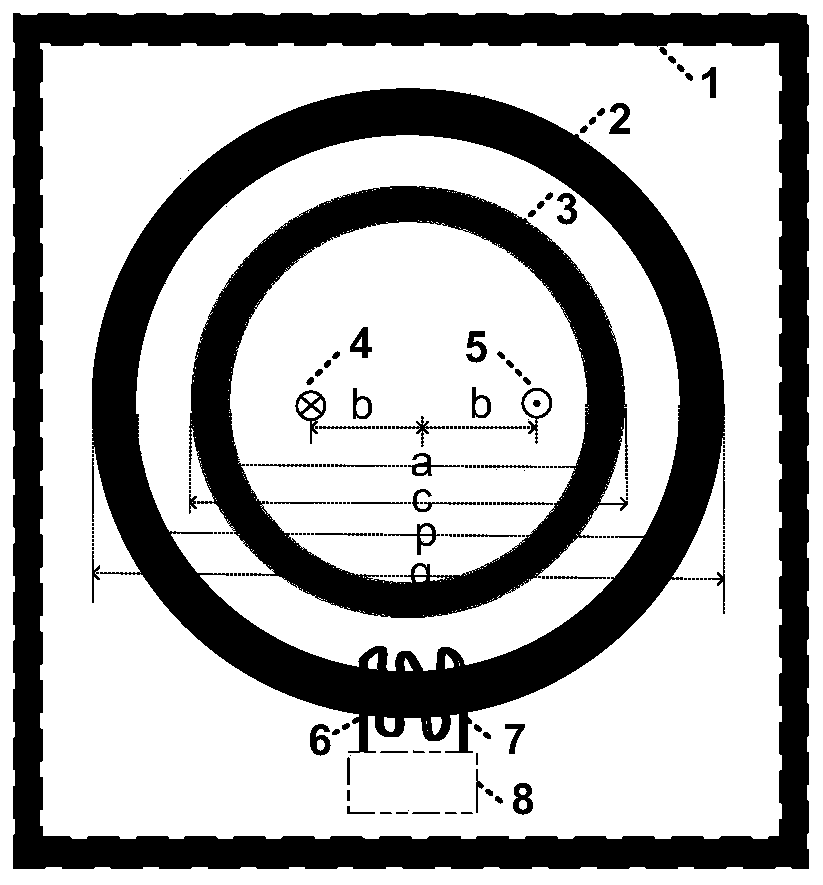

Design method of double-magnetic-core measurement differential leakage current sensor

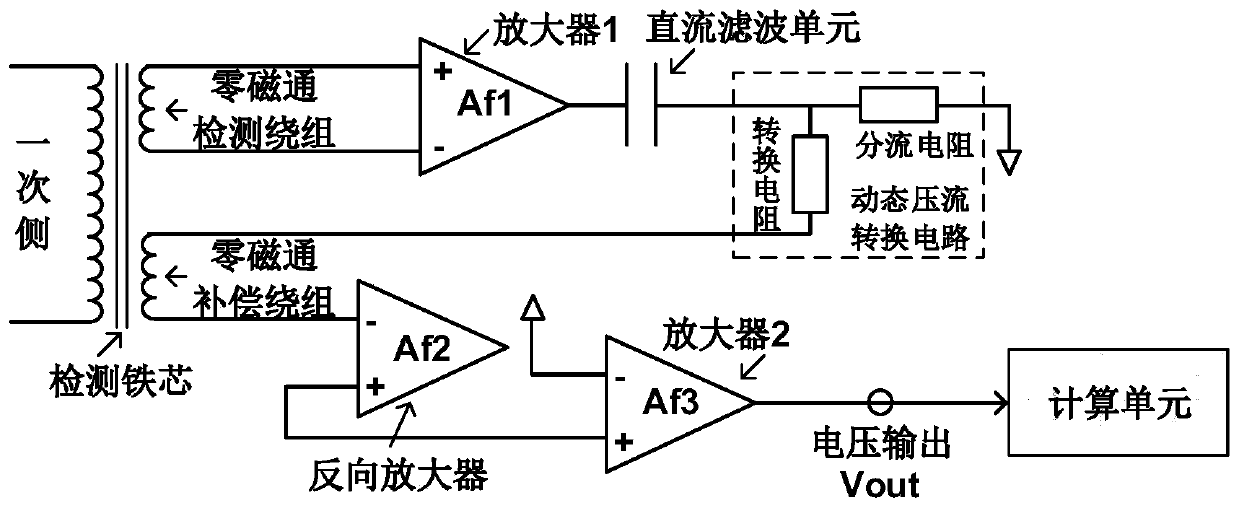

A technology of leakage current and design method, applied in the direction of measuring current/voltage, measuring electricity, measuring only current, etc., can solve the problems of unestablished current excitation, geometric size connection, etc., and achieve the effect of simple and direct design method and real-time monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

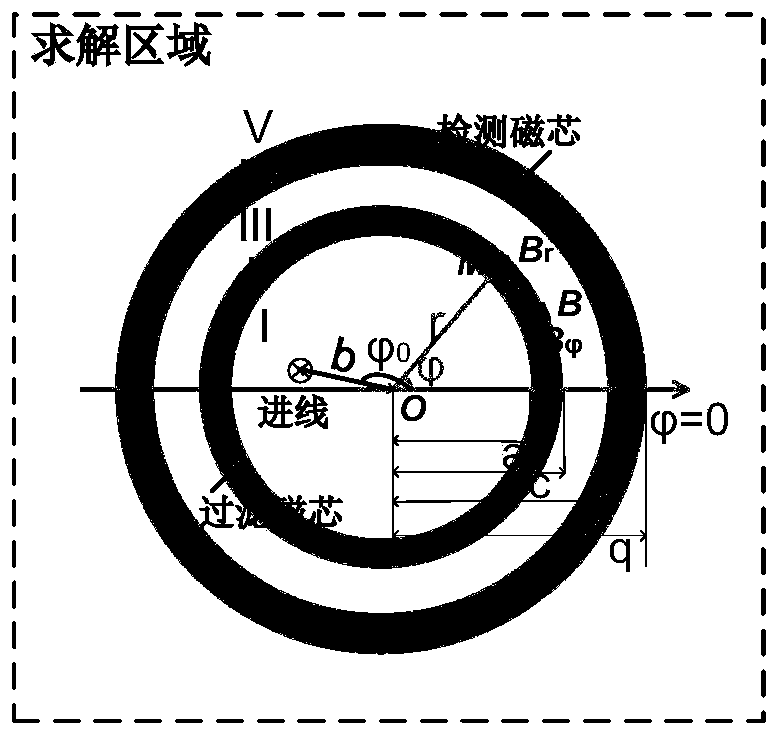

[0105] In order to verify the correctness of the above design algorithm, an embodiment is used to compare the established analytical algorithm with the finite element calculation results. The setting parameters are shown in Table 1. Wherein, the magnetic permeability of the two magnetic cores is the same.

[0106]

[0107] Figure 6 Provided that the analytical algorithm established by the present invention is compared with the finite element calculation results, it can be seen that in this embodiment, the calculation results of the two are very consistent (the finite element calculation results are discrete points distributed in the analytical solution nearby), verifying the correctness of the differential leakage current magnetic field analysis algorithm based on the double magnetic core measurement established by the present invention.

[0108] In summary, the present invention provides a design method for a dual magnetic core measurement differential leakage current s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com