Hybrid power gear shifting control method

A technology of hybrid power and control method, applied in the automotive field, can solve the problems of slow response speed, poor ride comfort experience, strong impact feeling and other problems in the shifting process, and achieve the effects of low cost, improved service life and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

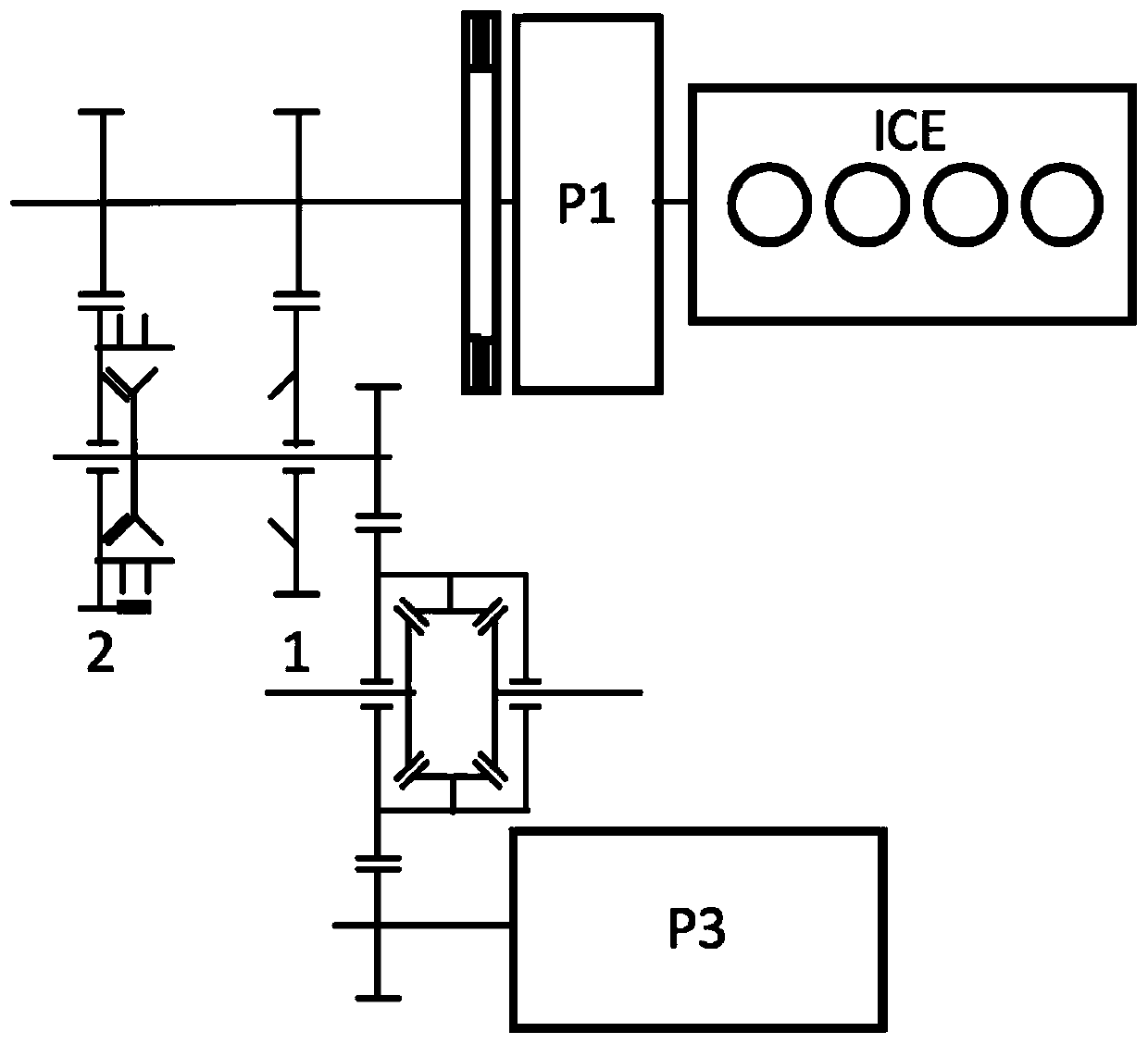

[0037] Such as figure 1 As shown, the present invention discloses a hybrid shift control method, comprising the following steps:

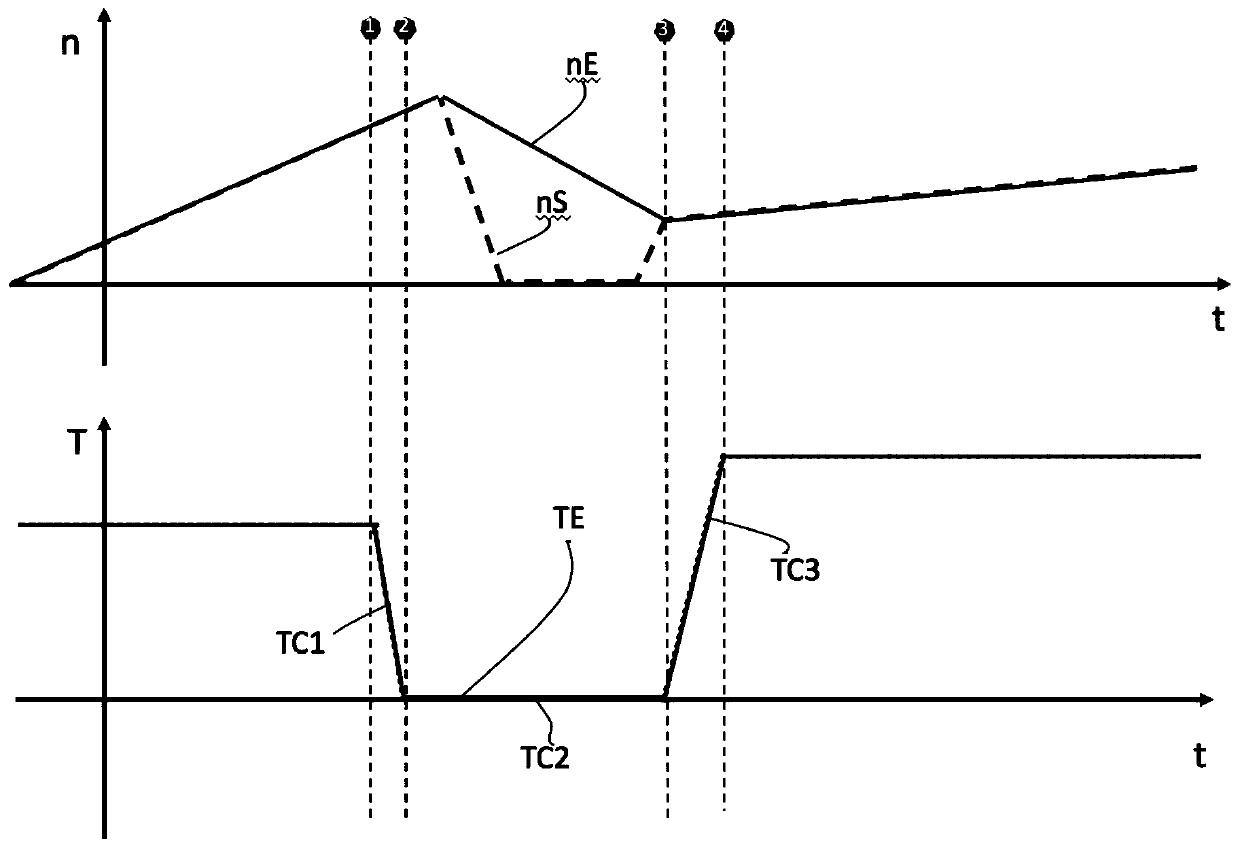

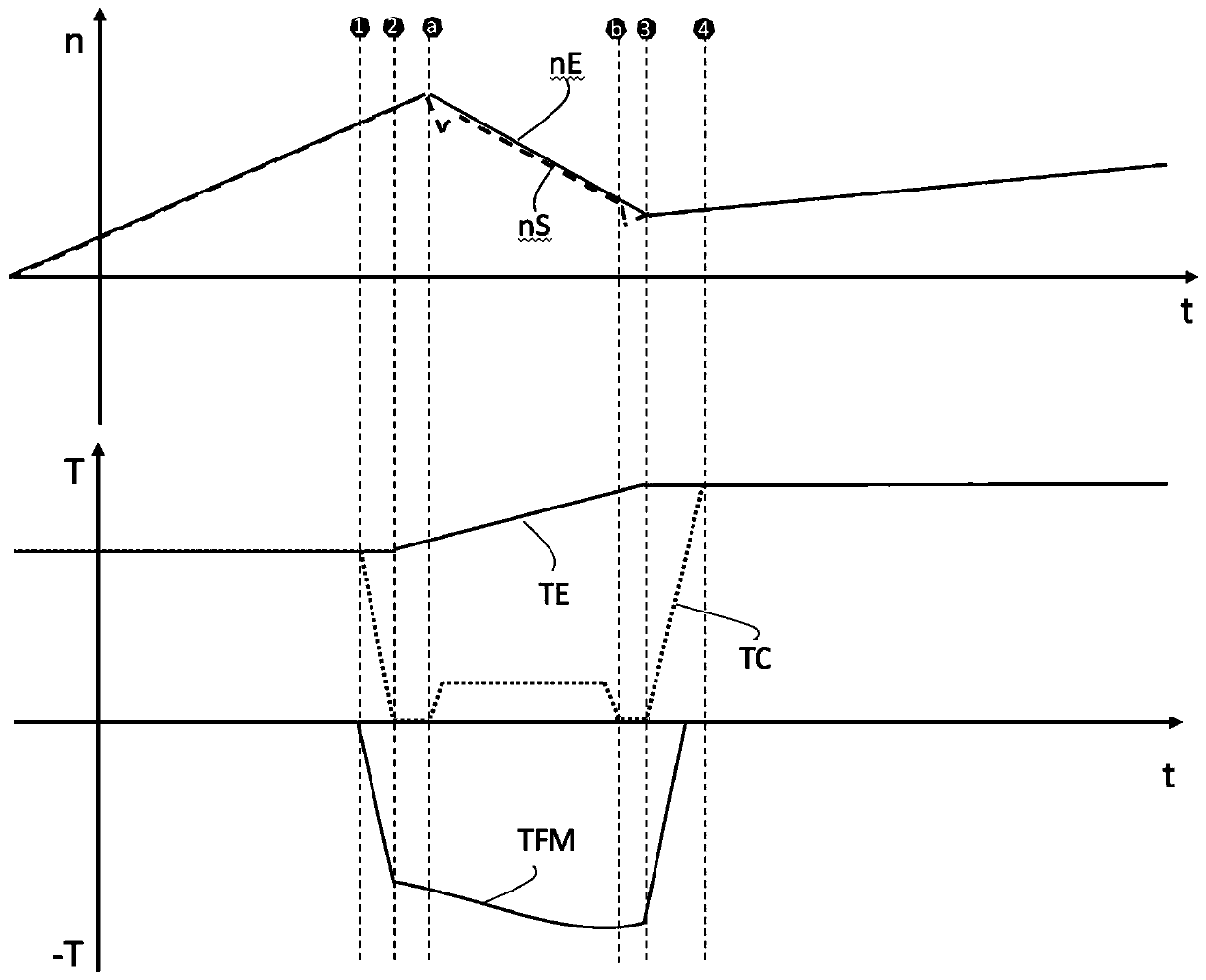

[0038] S1. Receive the shift command, control the clutch to disengage and enter the stage of disappearing transmission torque; at the same time, control the front-end motor to linearly increase and output a reverse torque in the opposite direction to the engine torque;

[0039] S2. Control the clutch to be completely disengaged and enter the transmission torque disappearing stage. At the same time, control the synchronizer in the shift system to disengage from the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com