Seamless upshift control method for hybrid power system

A control method and seamless technology, applied in the automotive field, can solve problems such as the inability to reasonably respond to changes in the driver's driving intention, the impact of vehicle acceleration, and the need to improve safety, so as to eliminate the need for discharge, solve the sense of impact, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

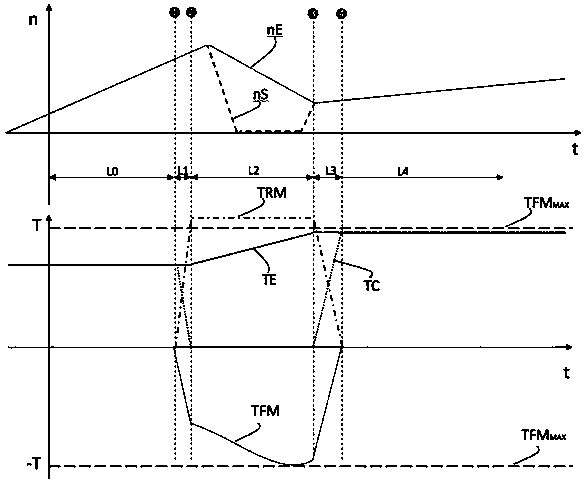

[0044] The invention discloses a method for seamless upshift control of a hybrid system, which specifically includes step-by-stage steps according to the working process of the clutch, and the step of controlling the front-end motor to adjust the rotational speed of the engine. At the beginning of shifting, the control purpose of the method of the present invention is to reduce the total output torque of the front end to 0, and at the same time increase the output torque of the rear end to: torque before shifting of the front end*low gear speed ratio / total speed ratio of the rear end. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com