A flow distribution control method for the central flue system of a high-rise building

A flue system and flow distribution technology, which can be used in heating methods, oil fume removal, vertical pipes, etc., and can solve problems such as high energy consumption, low efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

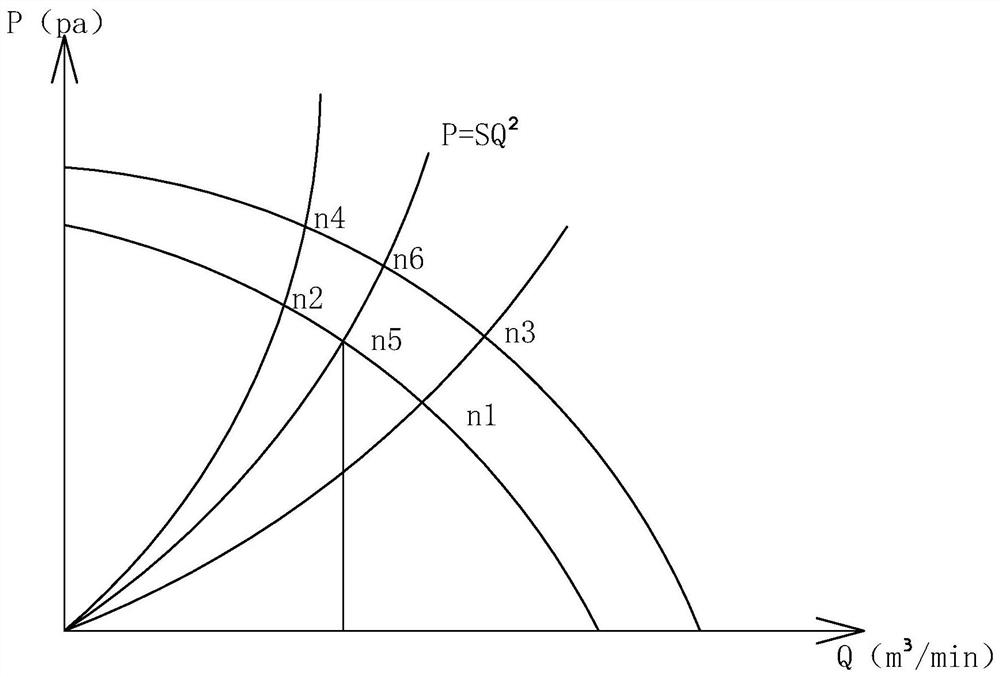

[0049] Such as figure 1 As shown, the flow distribution control method of this embodiment can measure different gears s in advance, and the relationship between flow Q and flow Q at different speeds n can be fitted into a function formula Q(s,n)=A s +B s n+C s no 2 +D s no 3 , you can also directly enter the second gear speed n1 corresponding to the flow rate Q1, n2 corresponding to the flow rate Q2, etc. into the table, and then when the actual second gear is running at n5, you can use the Newton difference or Lagrangian difference and other difference functions Calculate the actual flow Q5 at this time, and then use the intersection of the resistance curve and the PQ curve to estimate the flow after the gear is adjusted, or directly adjust the gear according to the ratio of the target flow to the current actual flow.

[0050] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com