A kind of booster device for numerical control punching machine that reduces punching time

A technology of CNC punching machine and booster device, which is applied in the direction of stripping device, forming tool, manufacturing tool, etc., and can solve problems affecting product quality, plate or hole deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

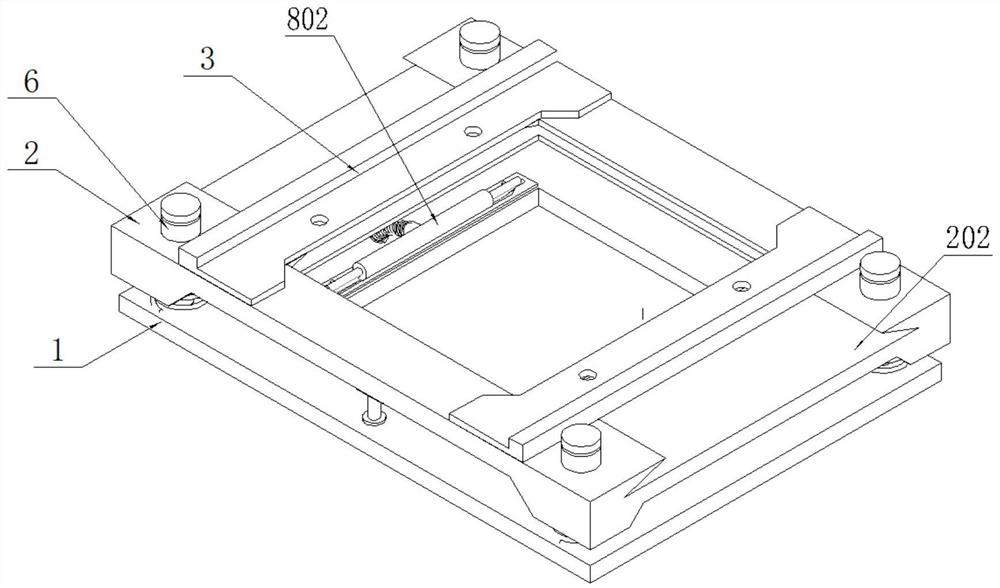

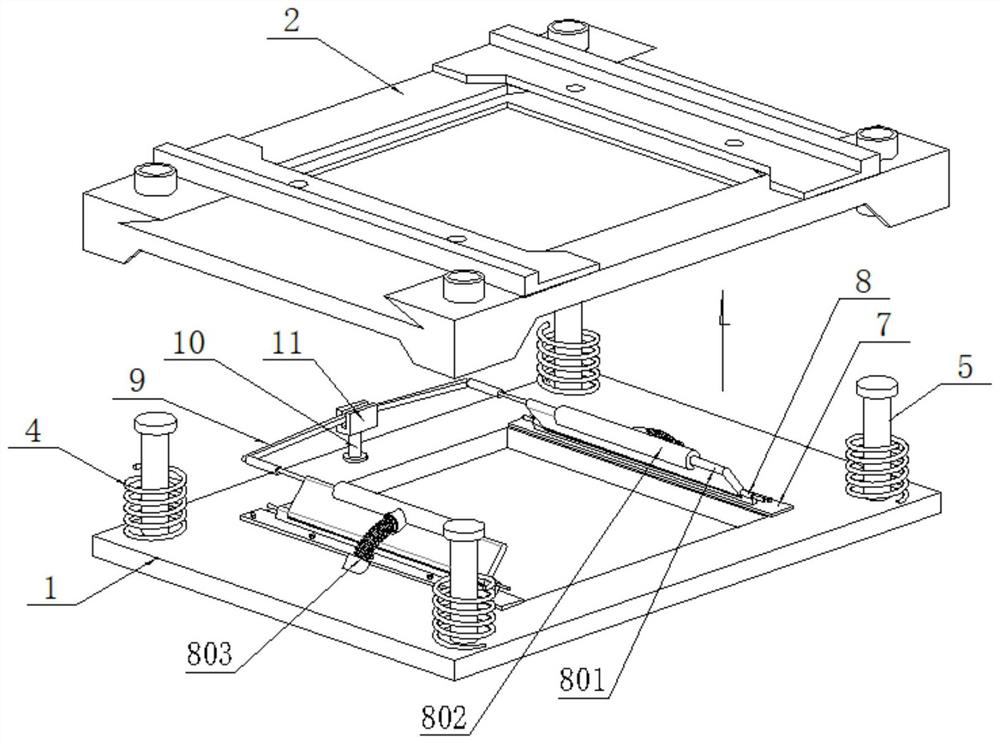

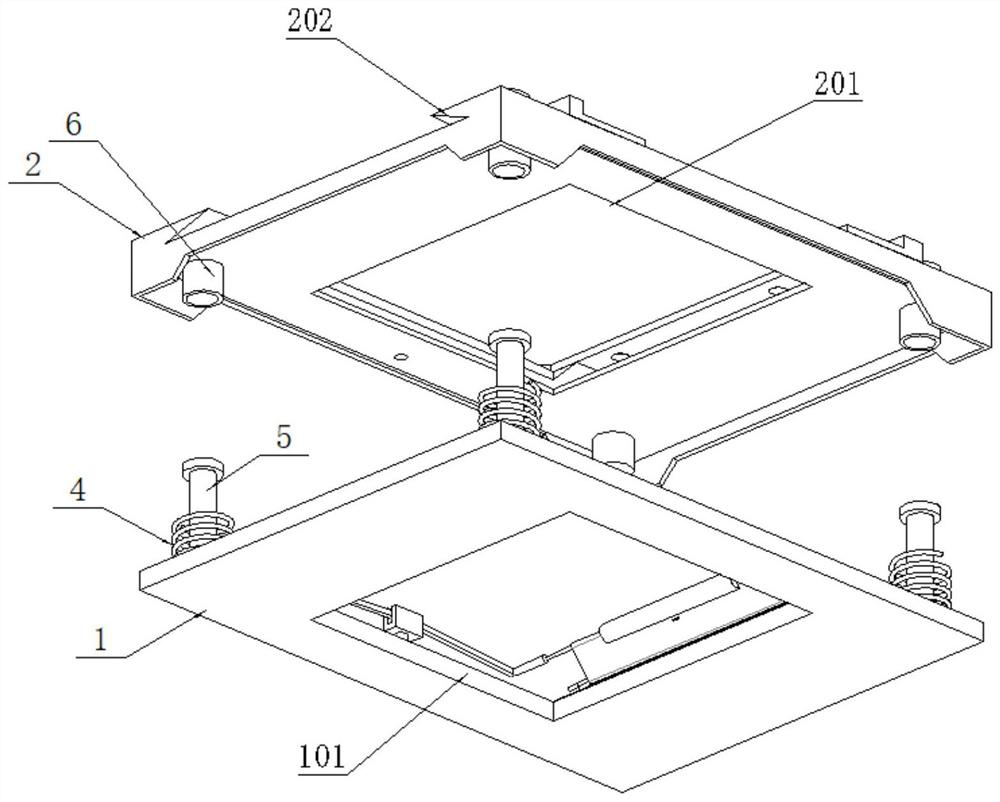

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a kind of force boosting device for numerically controlled punching machine which can reduce the stamping time, which comprises a stripping bottom plate 1, a top seat 2 and a punch head fixing plate 3; The guide post 5 of the cap structure, a cylindrical spring 4 is also set on the four guide posts 5; a guide sleeve 6 runs through the four corners of the top seat 2, and the top seat 2 passes through these four guide posts. The sleeve 6 is slidably fitted on the stripping bottom plate 1, and the top seat 2 forms spring contact with the four springs 4 on the stripping bottom plate 1. Bottom grooves 101 are respectively provided on the stripping bottom plate 1 at the bottom and the top seat 2 at the top. and the top groove 201, the two stamping head fixing plates 3 are located on both sides of the top groove 201, thus as figure 2 , image 3 as well as Figure 4 As shown, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com