Adaptive Variable Impedance Control Method for Clamping Mechanism of Fruit Sorting Parallel Robot

A technology of clamping mechanism and control method, which is applied in the field of agricultural parallel robot control, can solve the problems of not being able to adapt to changes in fruit quality and position, and achieve the effects of improving adaptability, improving control performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

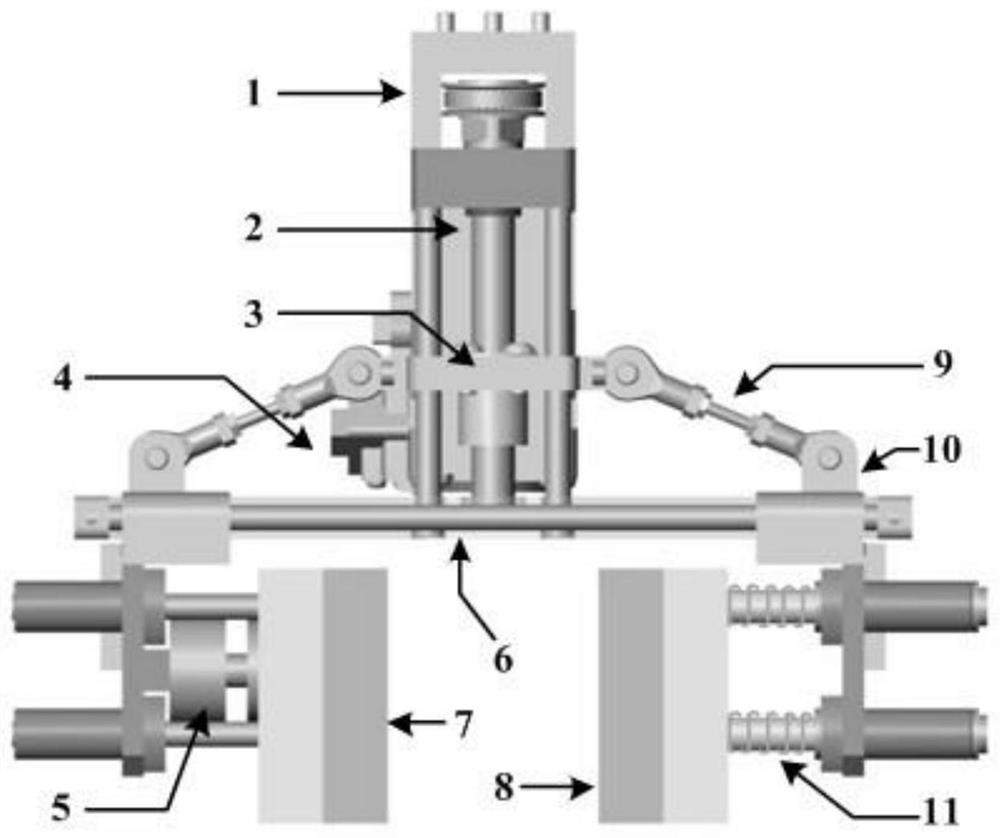

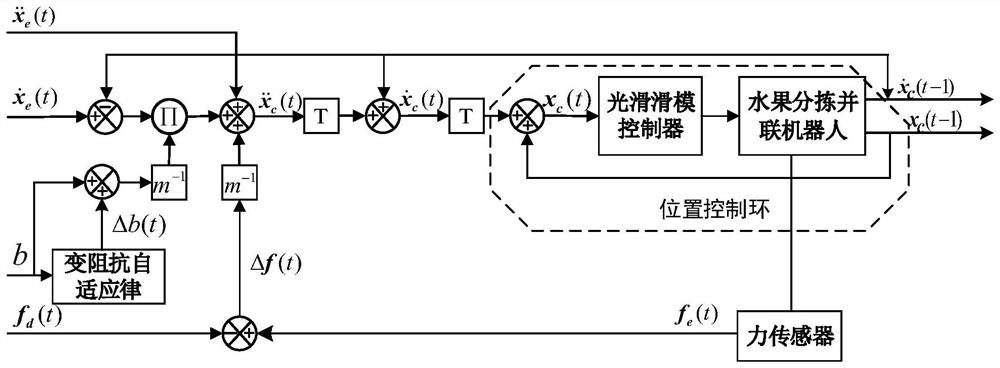

[0111] The invention provides an adaptive variable impedance control method for the clamping mechanism of parallel fruit sorting robot aiming at the problem that the clamping mechanism of parallel fruit sorting robot can clamp string fruits without damage. The method needs to establish a mathematical model of the clamping mechanism of parallel fruit sorting robot, improve the adaptability of the system to clamping speed and clamping load change, and improve the performance of impedance control, so that the nondestructive clamping of parallel fruit sorting robot can be well realized. The principle diagram of adaptive variable impedance control of clamping mechanism of fruit sorting parallel robot is as follows Figure 2 As shown, the specific implementation of the control method is as follows:

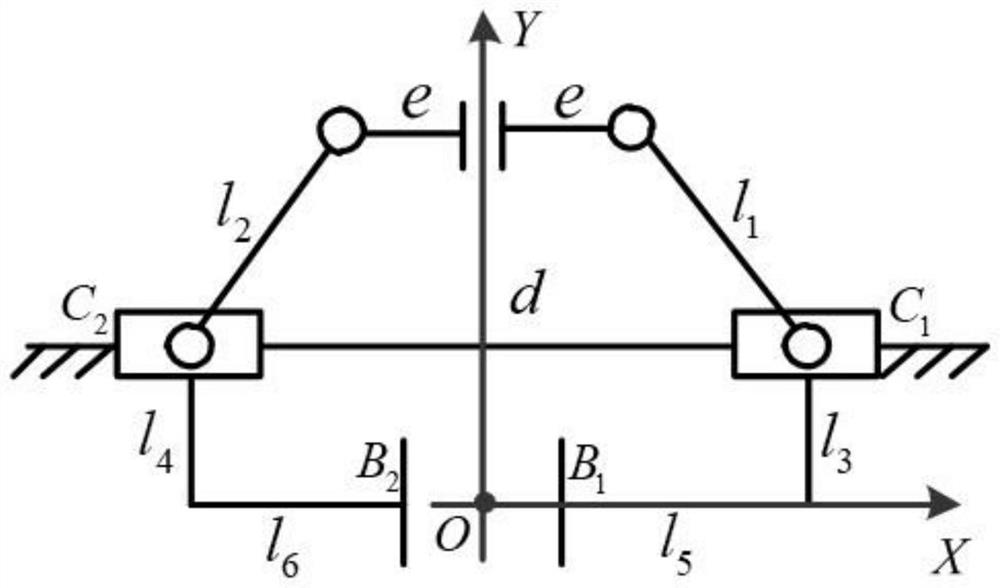

[0112] 1. Solve the conversion relationship between the rotation angle of the active joint screw and the position of the clamping finger of the clamping mechanism.

[0113] at Figure 2 Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com