Anti-falling bag feeding mechanism

An anti-dropping and bag-holding technology, applied in the direction of tubular objects, packaging, packaged item types, etc., can solve problems such as falling flat pockets, and achieve the effect of ensuring the success rate of bagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

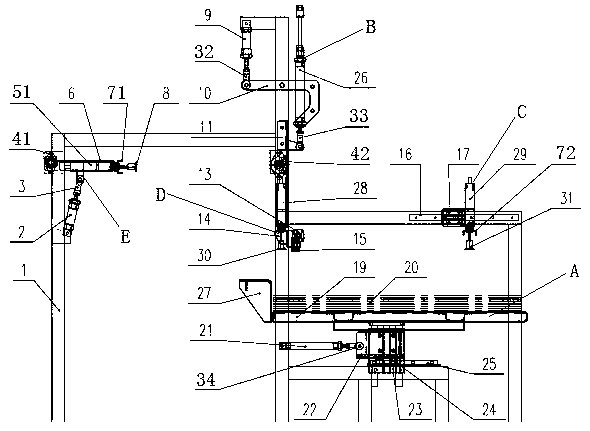

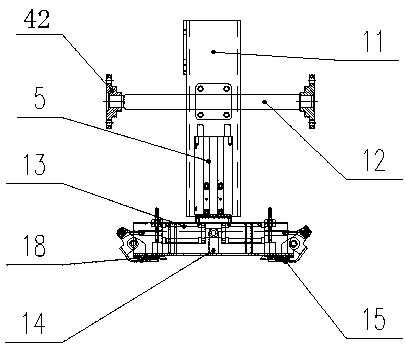

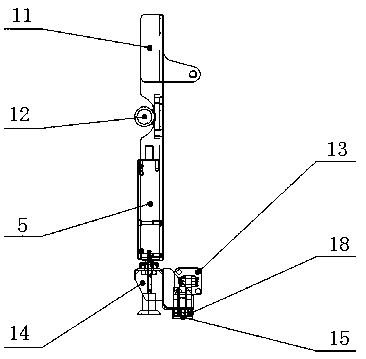

[0009] see Figure 1-Figure 3 , an anti-drop bag loading mechanism in the present invention includes: a material storage mechanism A, a bag loading mechanism B, a bag tail processing mechanism C, a bag clamping mechanism D, and a counter-suction bag opening mechanism E. The material storage mechanism A is installed on the frame body 1 The bottom of the right end is used to store the flat pocket 20. The bag tail processing mechanism C is housed on the frame body 1 above the material storage mechanism A, and is positioned at the top of the flat bag 20 bag tail positions. On the frame body 1 above the left end of the storage mechanism A, a bag loading mechanism B is installed; at the bottom of the bag loading mechanism B, a bag clamping mechanism D is installed, which is used to clamp the flat bag 20 during the bag loading process to prevent it from falling fall. On the frame body 1 on the left side of the bag-up mechanism B, a counter-suction bag-opening mechanism E is housed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com