A telescopic track installation structure and adjustment method at the beam joints of horizontal and vertical curve superimposed sections

A technology of telescopic rail and installation structure, applied in the field of rail engineering, can solve the problems of high risk factor and difficult construction of cross-river bridges, and achieve the effect of satisfying traffic and comfortable riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

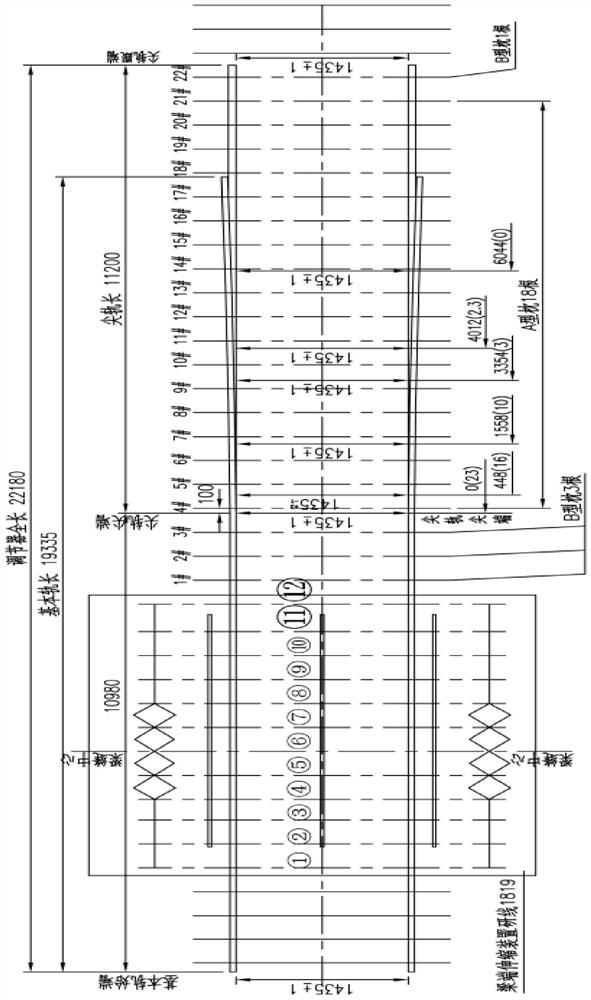

[0036] refer to figure 1 As shown, this embodiment is a telescopic rail installation structure at the beam joints of the horizontal and vertical curve superimposed sections, including beam end telescopic devices and rail telescopic regulators arranged above the bridge joints and on the rail lines on both sides. lie on a horizontal curve and a vertical curve at the same time;

[0037] The center line of the telescopic device at the beam end coincides with the center line of the beam joint;

[0038] The basic rail and the switch rail of the rail telescopic adjuster are respectively installed on both sides of the beam gap, and the basic rail is located on the approach bridge side, and the switch rail is located on the main bridge side;

[0039] The basic rail of the rail telescopic adjuster is fixedly connected with at least one steel sleeper on the approach bridge side of the beam end telescopic device; the rail telescopic adjuster is located outside the main bridge side of the...

Embodiment 2

[0046] This embodiment is a method for adjusting the telescopic track at the beam joint of the superimposed horizontal and vertical curves, which can be used for the track installation structure in Example 1. The steps of the adjustment method include:

[0047] Place the telescopic device at the beam end within the preset position range on the concrete beam surface at the beam joint;

[0048] Lift the telescopic device at the beam end to the design elevation, and adjust the center line and lateral position to the predetermined position;

[0049] The beam end telescopic device is fixed by the rail support frame, the tool rail on the beam end telescopic device is removed, the basic rail of the rail telescopic adjuster is connected with at least one steel sleeper on the approach bridge side of the beam end telescopic device, and the rail telescopic adjustment The basic rail of the device is located on the side of the approach bridge, and the point rail is located on the side of t...

Embodiment 3

[0064] The following uses a specific application example to illustrate the installation structure and adjustment method. refer to figure 1 For example, the bridge joint of a horizontal and vertical curve section is 800mm, the planned track line is on a curve with a radius of 2000m, and the curve is also on a vertical curve with a radius of 3550m.

[0065] Utilize the present invention to carry out the design of installation structure such as figure 1 , The telescopic device at the beam end includes 12 steel sleepers ①-⑫, of which 3 steel sleepers ⑤-⑦ are suspended above the beam joints. The basic rail of the rail telescopic regulator faces the approach bridge side, the tip rail faces the main bridge side, the rails of the basic rail are connected to the steel sleepers of the telescopic devices at both ends, and there are 3 sleepers 1# connected to the basic rails on the outside of the main bridge side of the telescopic device at the beam end -3#, the three sleepers use B-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com