A Multi-objective Flexible Job Shop Scheduling Method Based on Two-layer Genetic Algorithm

A genetic algorithm and flexible operation technology, applied in the field of multi-objective flexible job shop scheduling based on two-layer genetic algorithm, can solve the problems of local optimization and insufficient population diversity, and achieve the effect of good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

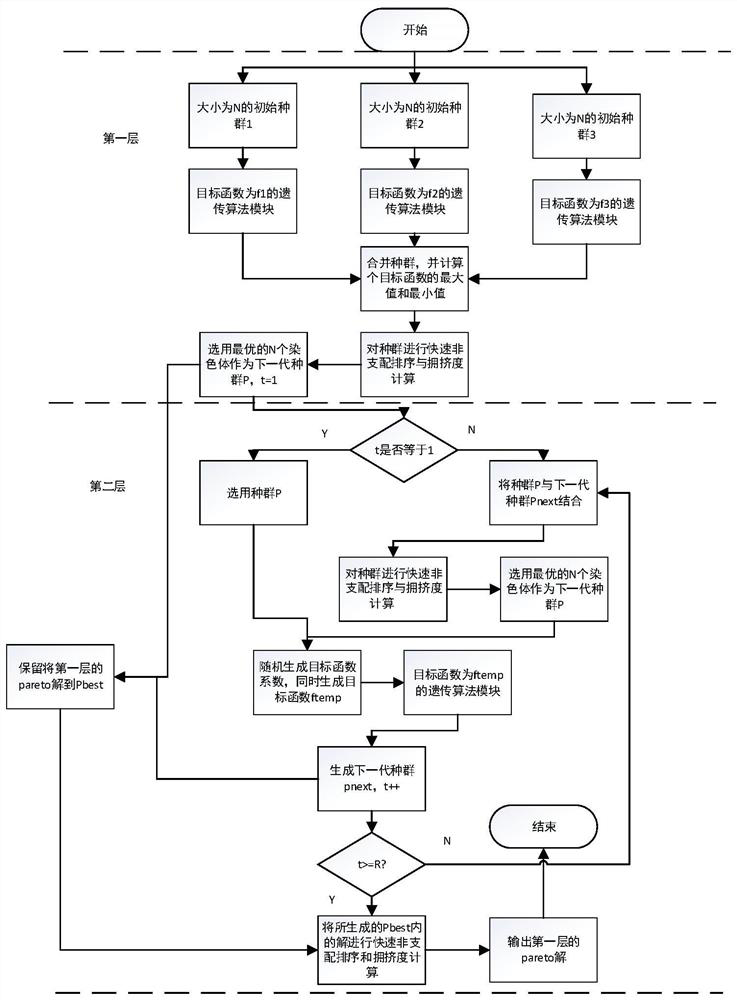

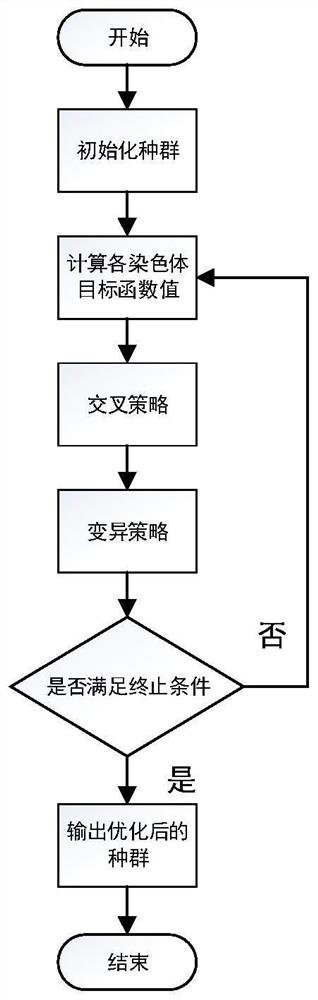

Method used

Image

Examples

Embodiment

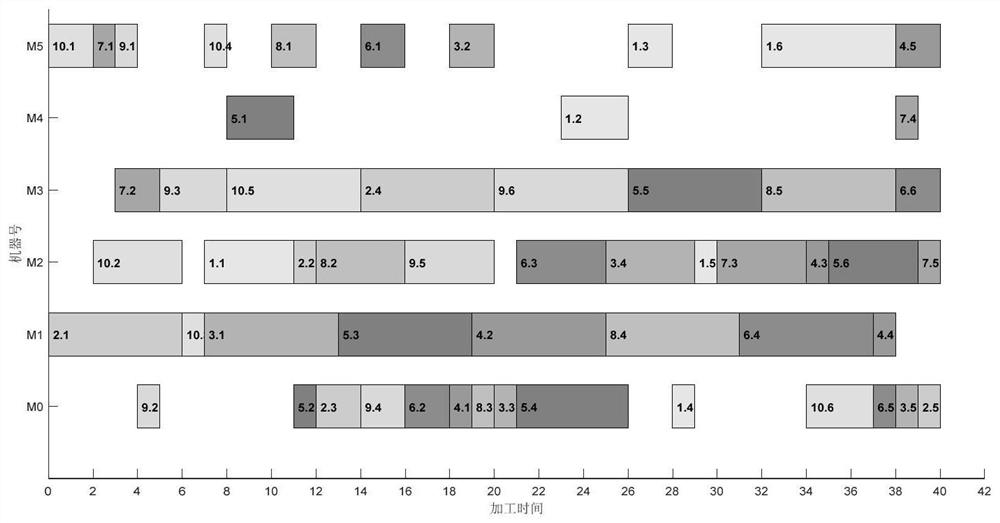

[0104] Such as image 3 shown.

[0105] Taking the Mk01 case as an example, this case is a classic case of flexible job shop scheduling with 10 workpieces, 6 optional processing procedures, and a total of 55 procedures. The maximum workpiece completion time f 1 , the maximum machine load f 2 , the total machine load f 3 Multi-objective optimization of flexible job shop scheduling for optimization objectives.

[0106] The detailed data of the Mk01 case is shown in the table below:

[0107]

[0108]

[0109] The non-dominated frontier that can be obtained using this case is shown in the table below:

[0110]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com