Glue spraying device for rollers

A technology of spraying glue and rollers, which is applied in the direction of spraying devices, etc., which can solve the problems of insufficient production efficiency, high labor intensity, and inconvenient lifting and turning of rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

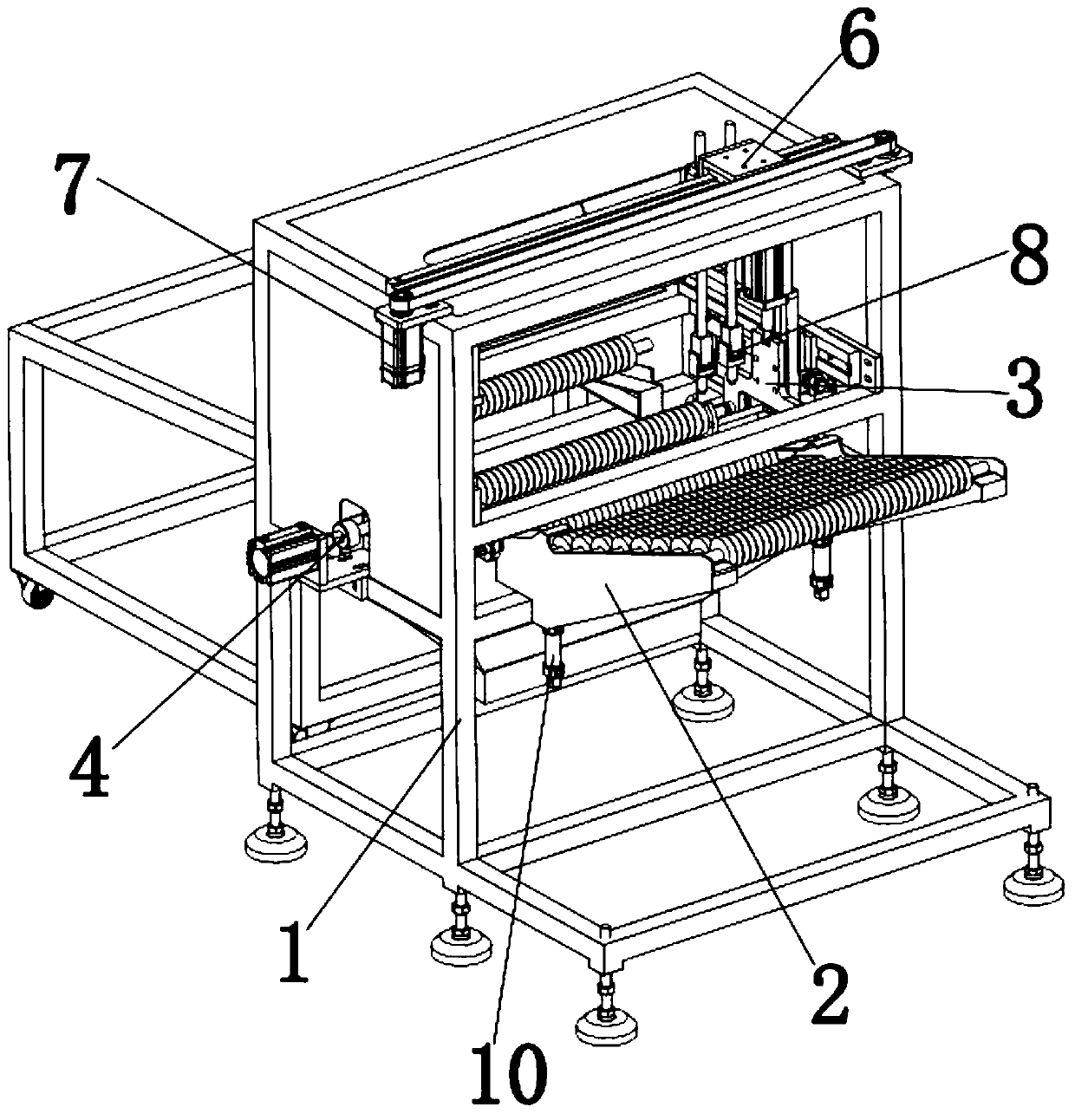

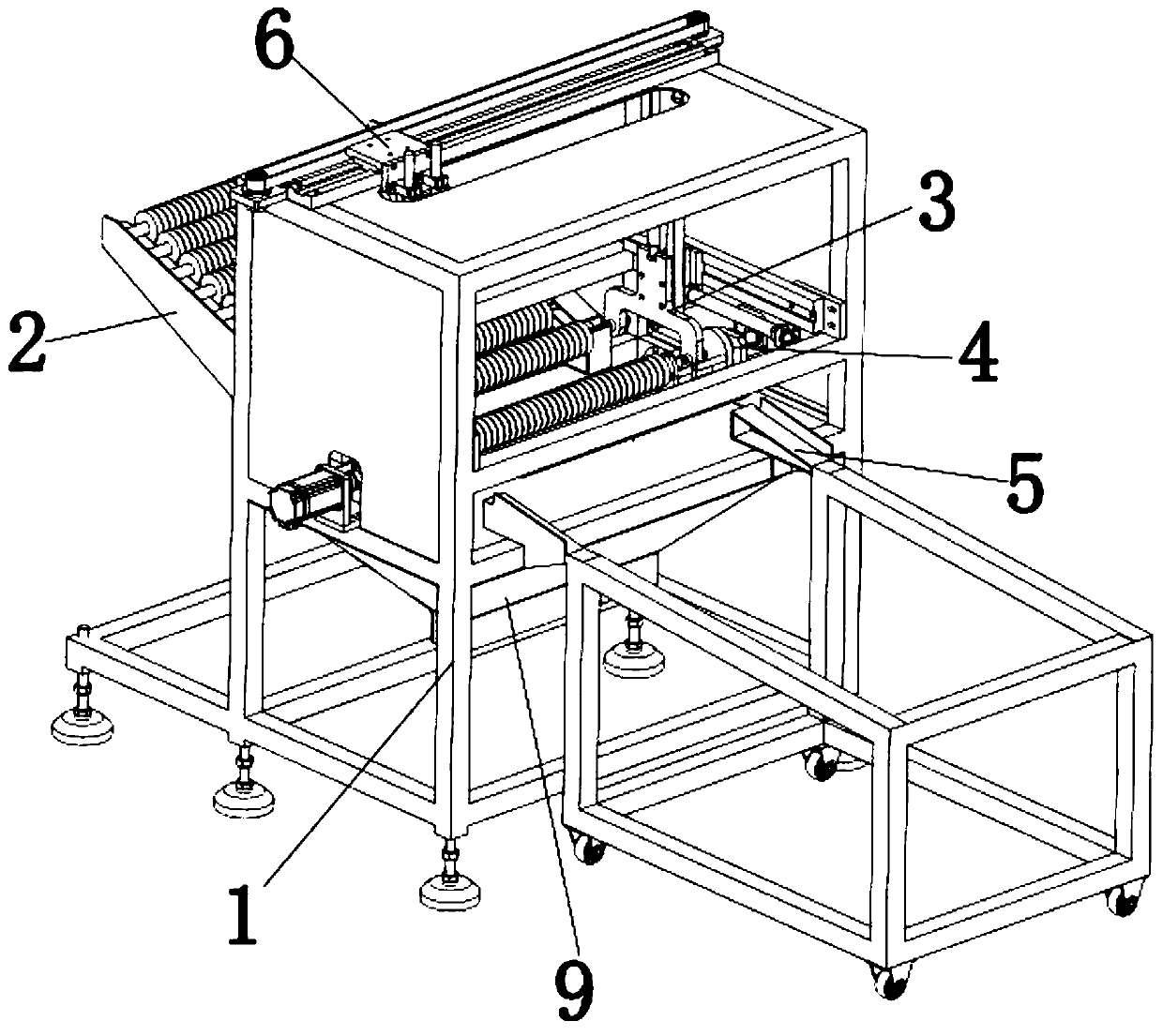

[0040] A roller glue spraying device, comprising: a frame 1, a discharge seat 2, a transfer assembly 3, a rotary drive assembly 4, a glue spray assembly and a material receiving seat 5, the rotary drive assembly 4 is installed on the frame 1, and the discharge seat 2 and the material receiving seat 5 are arranged on both sides of the rotary drive assembly 4, the transfer assembly 3 is slidably installed between the material discharging seat 2 and the material receiving seat 5, the glue spraying assembly is slidably installed on the frame 1, and the glue spraying assembly is located on Rotate the top of the drive assembly 4.

[0041] In this way, use a round tube to pass through the through hole in the middle of the rollers, the rollers are arranged along the round tube, each string of rollers is arranged on the discharge seat 2 in turn, and the transfer component 3 transfers the round tube with the rollers to the rotary drive component 4 Next, the rotating drive assembly 4 dri...

Embodiment 2

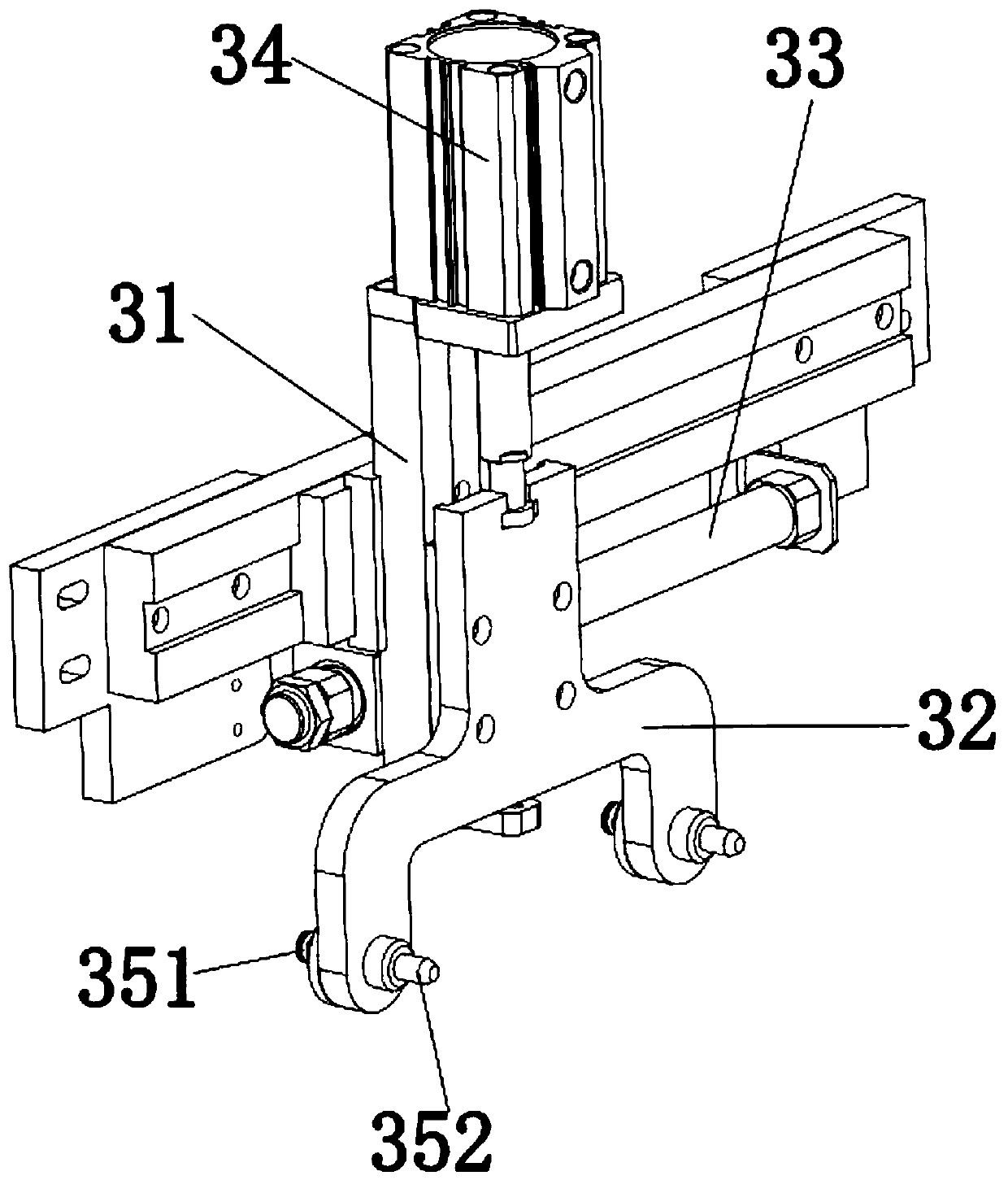

[0049] In this embodiment, two groups of transfer assemblies 3 are arranged at intervals, and the transfer assembly 3 includes a second slide seat 31, a second lifting seat 32, a second drive assembly 33, a second linear motion power device 34 and a telescopic rod assembly 35, The second sliding seat 31 is slidably installed on the frame 1, and the second driving assembly 33 is installed on the frame 1. The second driving assembly 33 is connected with the second sliding seat 31 to drive the second sliding seat 31 to slide, and the second lifting The seat 32 is slidably installed on the second sliding seat 31, the second linear motion power device 34 is fixed on the second sliding seat 31, the output shaft of the second linear motion power device 34 is connected with the second lifting seat 32, and the telescopic rod assembly 35 Installed on the second lifting seat 32. Specifically, the second linear motion power device 34 is an air cylinder. Specifically, the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com