Discharging hopper for bag feeding type packaging

A blanking and hopper technology, applied in the field of blanking hoppers, can solve the problems of elastic and viscous materials blanking and blocking, and achieve the effect of ensuring high-speed and high-efficiency operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

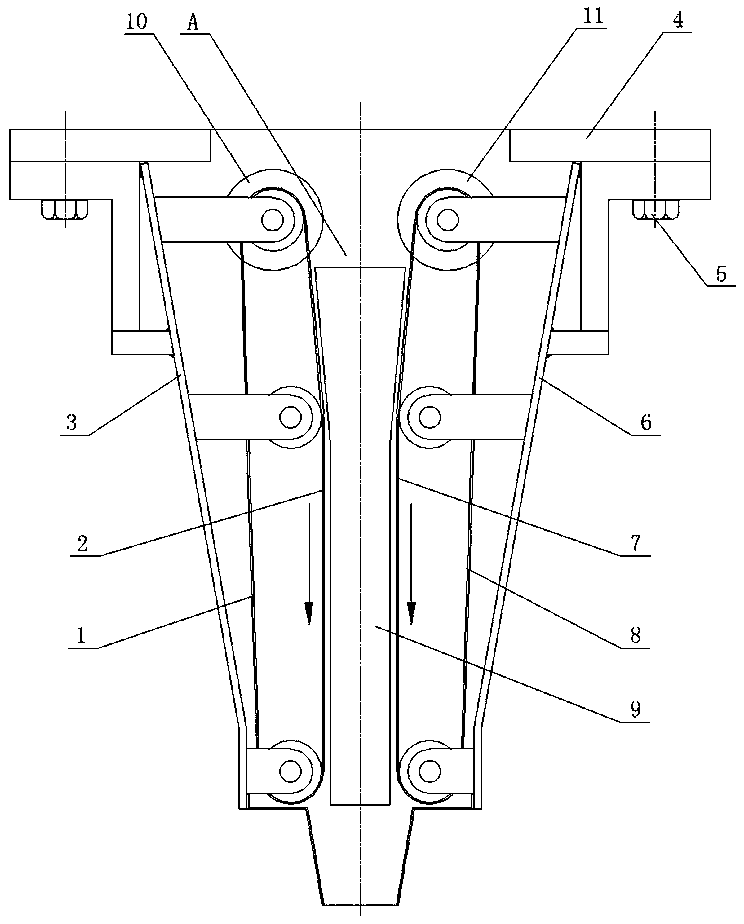

[0011] As shown in the figure, the blanking hopper for bag-packing of the present invention has a vertical blanking passage A provided in the middle of the hopper, and the blanking passage A is surrounded by side walls around the front, rear, left, and right sides, wherein the left side wall 2 1. The right side wall 7 moves downward synchronously during the blanking work, and the material in the blanking channel A is quickly sent downward, wherein the front side wall 9 and the rear side wall are fixedly arranged, and the left and right side walls of the blanking channel A Surround the tapered channel in the upper section. The left side wall 2 of the unloading channel A is formed by the right conveying surface of the left conveyor belt 1, the right sidewall 7 of the unloading channel A is formed by the left conveying surface of the right conveying belt 8, and the transmission of the left conveying belt 1 is formed by the left conveyor belt 1. Driven by motor 10, the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com