Rotary tower crane

A technology of tower cranes and jibs, which is applied to cranes and other directions, and can solve problems such as inconvenient high component weight and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

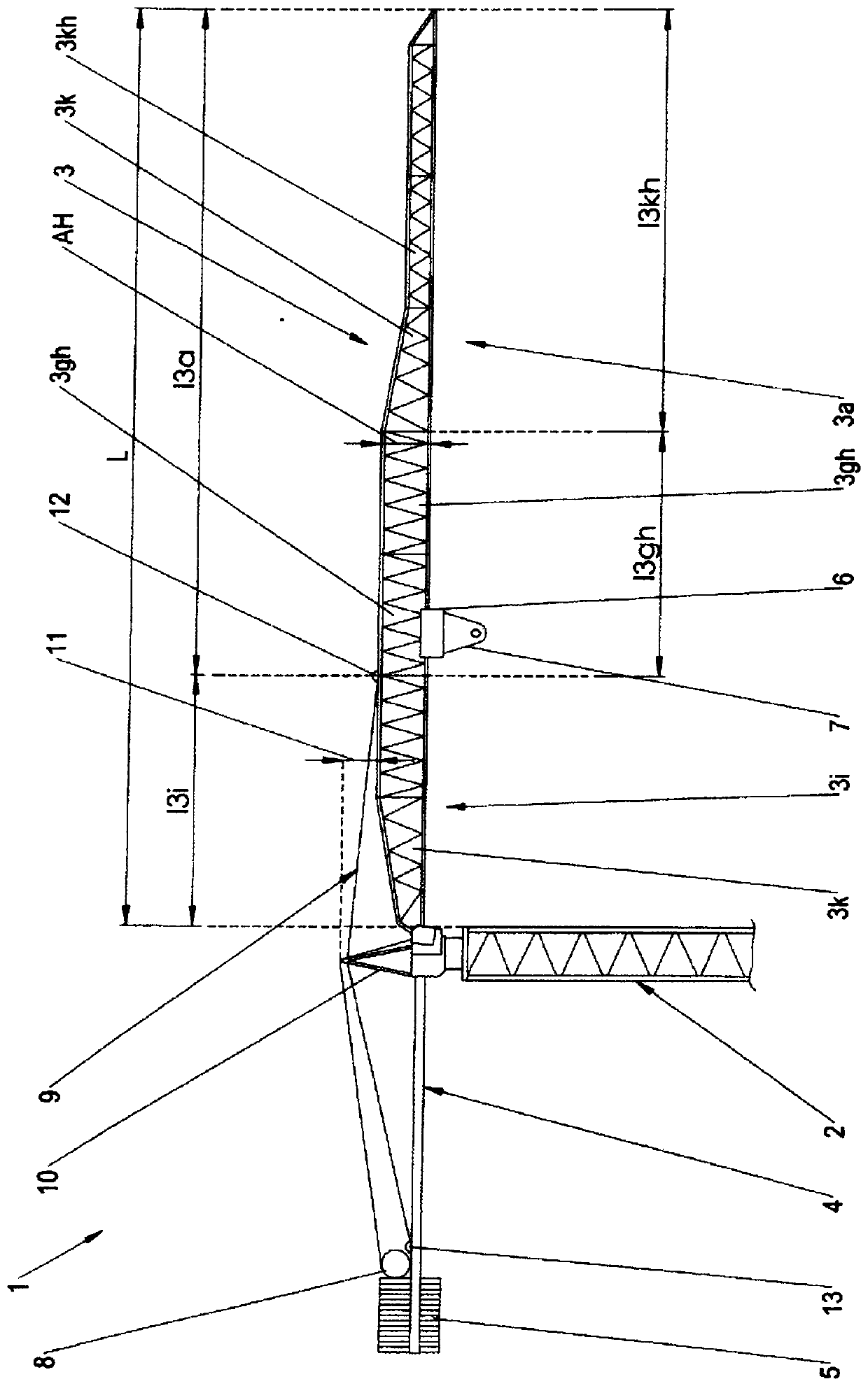

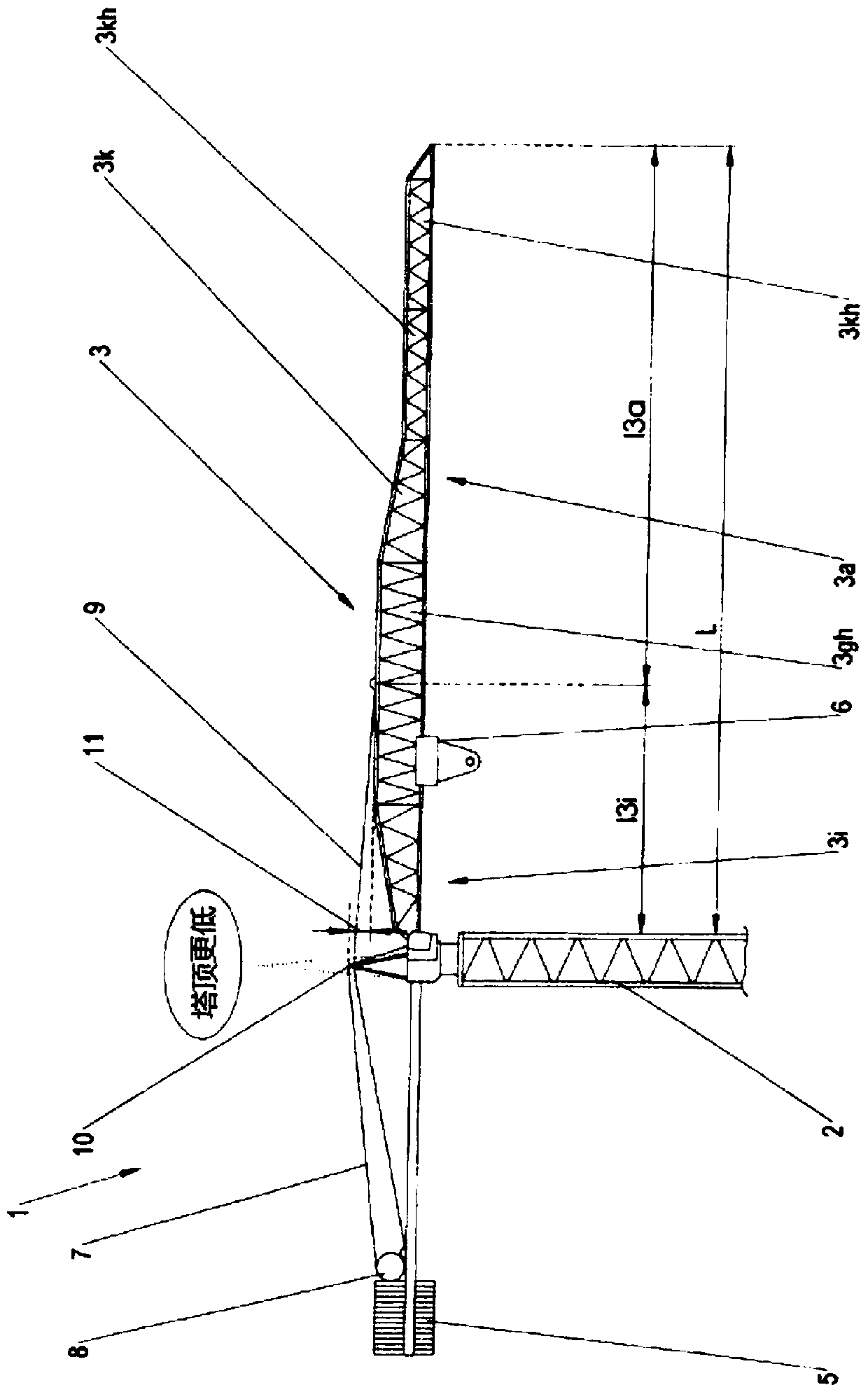

[0034] Such as figure 1 It is shown that the rotating tower crane 1 comprises a vertical tower 2 which may be formed as a mast and may for example have a rectangular cross-section.

[0035] A jib 3 , aligned generally in a flat manner (in particular, approximately horizontal), is articulated to the upper end of the tower 2 . A counterweight 5 , which can likewise be arranged in a flat manner (in particular horizontally) and which can support a counterweight 5 , can be provided at the side of the tower 2 opposite the jib 3 .

[0036] The trolley 6 may be arranged longitudinally advanceable at the jib 3 in a manner known per se to be able to lower and raise the hoisting wire 7 and the hoisting hook connected to it closer to the tower 2 or further away Tower 2. The hoisting wire rope 7 can advantageously be lowered and raised by means of a hoisting device 8 which can be arranged at the counterweight 4 near the counterweight 5 , in particular, immediately before the counterweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com