Craft technique for embossed-foil printed painting

A technology for printing and carving foil, applied in painting tools, decorative arts, special decorative structures, etc., can solve the problems of inability to realize foil printing, light, thin, simple, easy to copy, beautiful and unique, heavy and expensive, and lack of copper plate patterns. Good market prospects, low cost, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0022] A technique of engraving foil printing and painting, comprising the following steps:

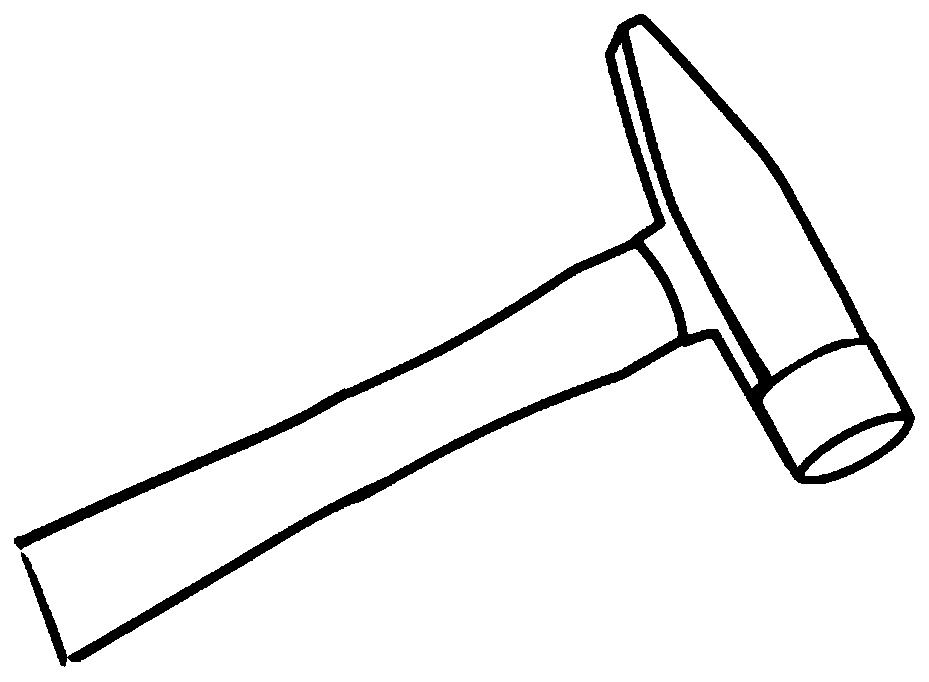

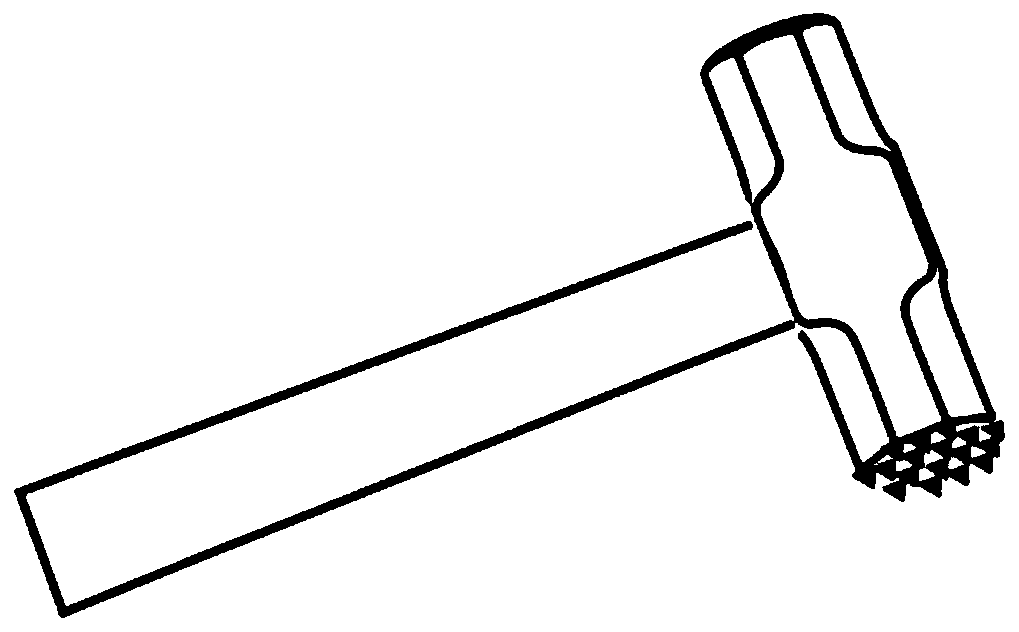

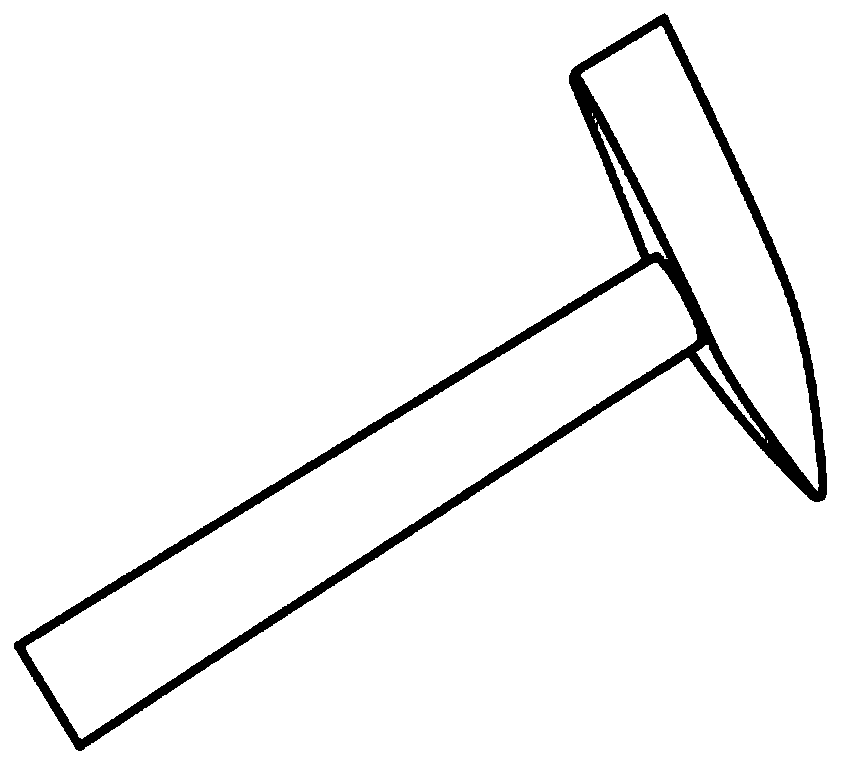

[0023] S1. Preparation: Grind bamboo (or wood), wood, cowhide, and rubber into round, oval, inverted triangular, and sharp knife heads respectively, and make repairs with wooden poles. Knife, made of wood, rubber, and cowhide to make flat head engraving hammer, cone point engraving hammer, conical engraving hammer respectively, prepare surrounding template, clay (ceme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap