Bridge crane and sliding contact line dust cleaning device thereof

A technology of bridge crane and cleaning device, which is applied in the direction of transportation and packaging, cleaning methods and appliances, cleaning methods using gas flow, etc., which can solve problems such as high safety risks, affecting the production of metallurgical plants, and large losses due to production stoppages, so as to achieve safety High safety, the effect of preventing personal injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a trolley line dust cleaning device of a bridge crane, which can clean the dust on the trolley line without stopping the crane, which saves time and labor and has high safety. Another core of the present invention is to provide an overhead crane including the above-mentioned dust cleaning device.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

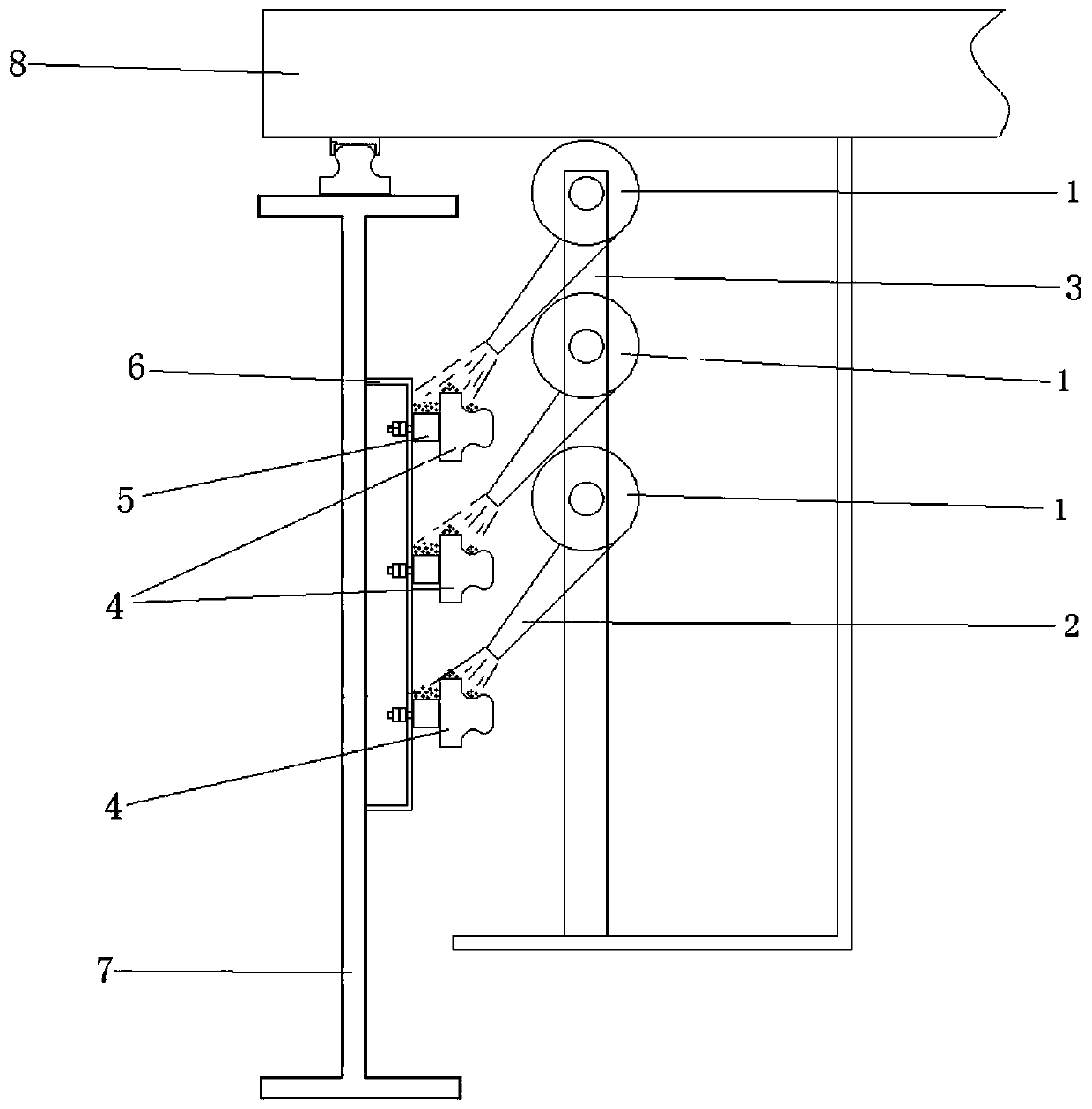

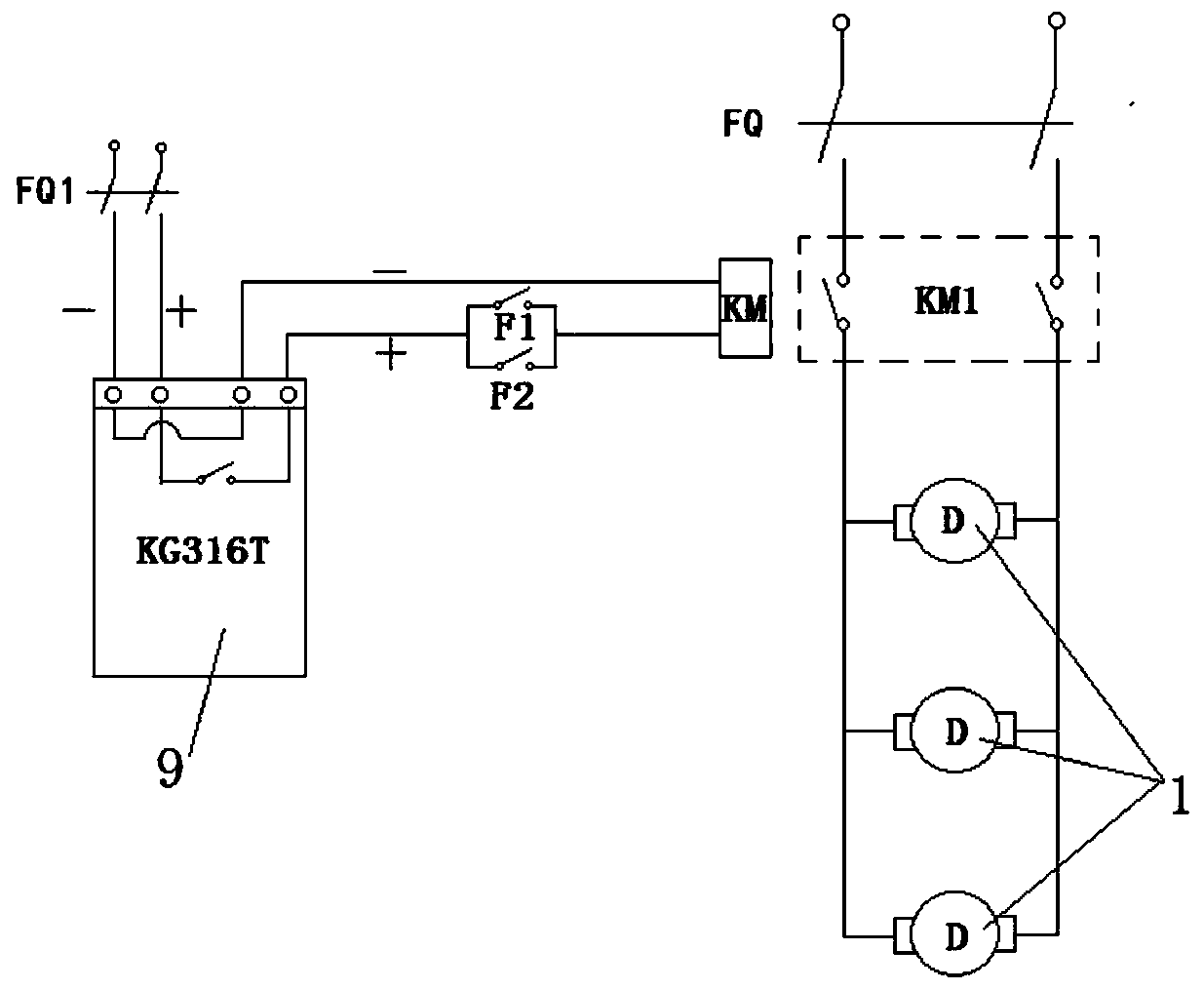

[0024] Please refer to figure 1 and figure 2 , figure 1 It is a side view of a specific embodiment of the trolley line dust cleaning device provided by the present invention; figure 2 It is an electrical control diagram of a specific embodiment of the trolley line dust cleaning device provided by the present invention.

[0025] The trolley line dust cleaning device of the bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com