Casting sand box internal processing device and casting sand box internal processing process

An internal treatment and sand box technology, applied in the direction of manufacturing tools, casting molding equipment, tools, etc., can solve the problems of difficult collection of sand particles, difficulty in seeing the inside of the sand box, fatigue, etc., and achieve the effect of improving the scraping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below with reference to the accompanying drawings. During this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the lines or the size of the components in the illustrations.

[0036] In addition, the following terms are defined based on the functions in the present invention, and may be different depending on the user, the operator's intention, or convention. Therefore, these terms are defined based on the entire content of this specification.

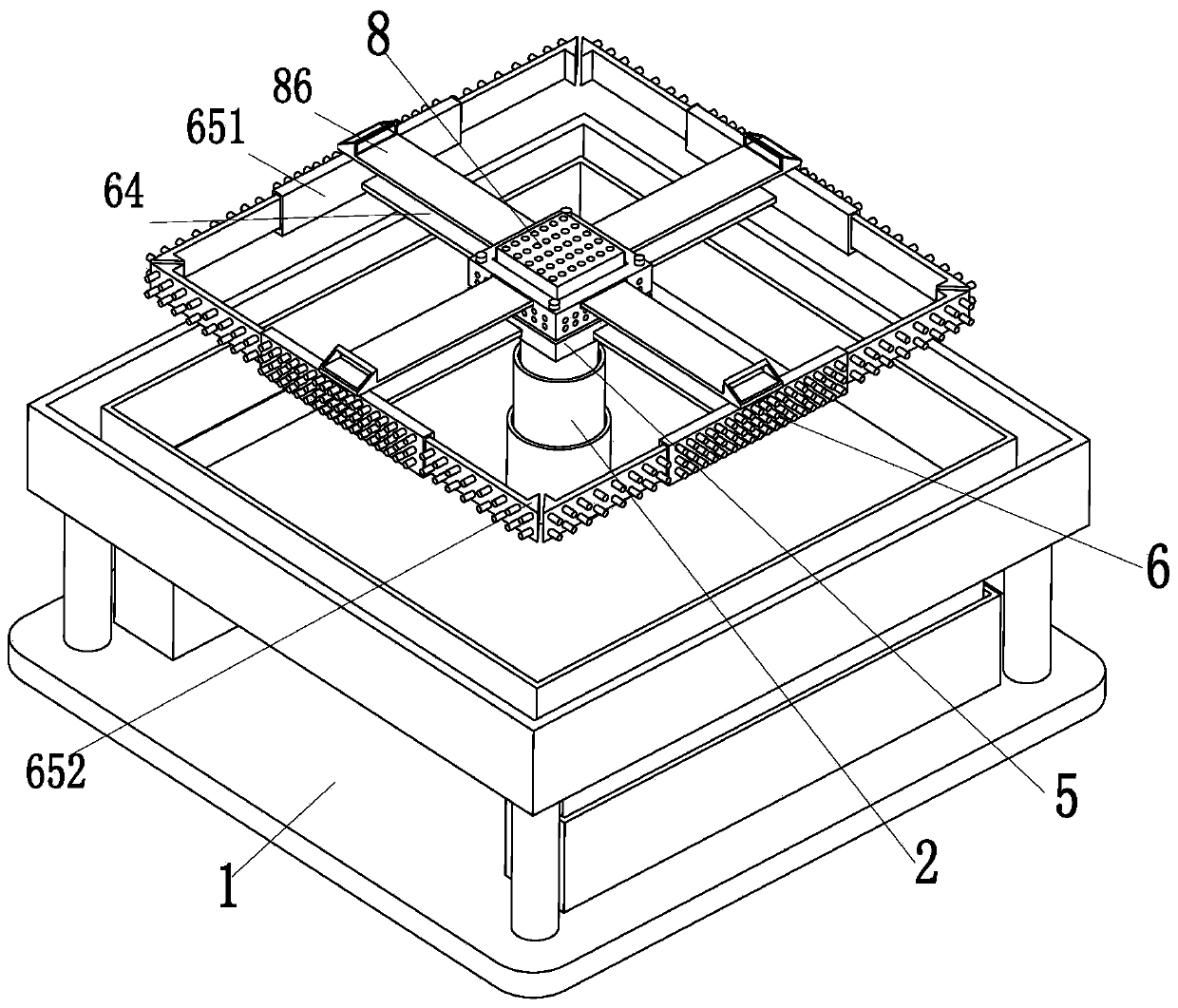

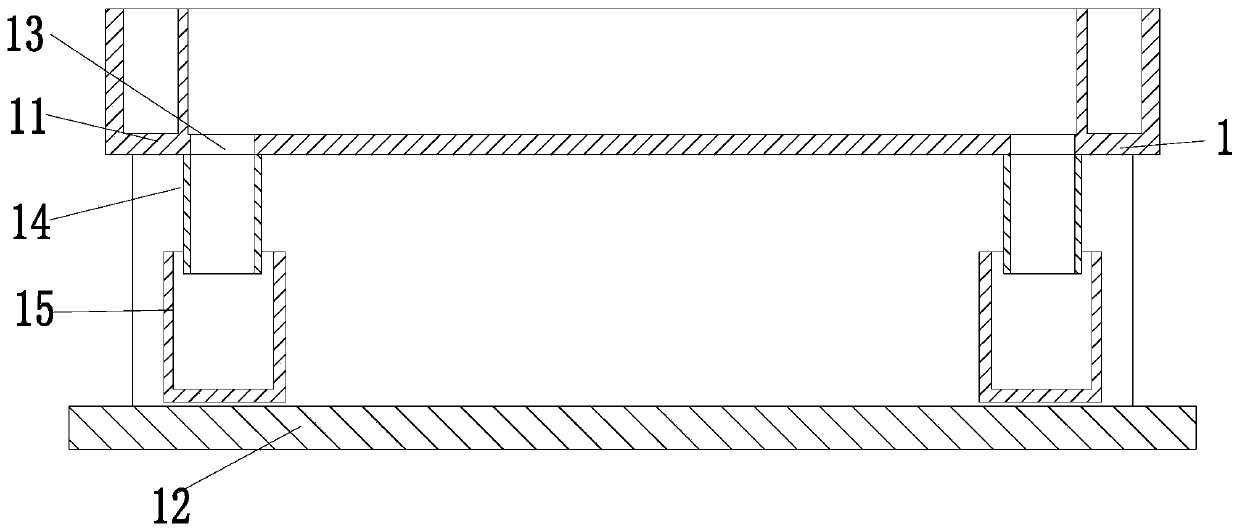

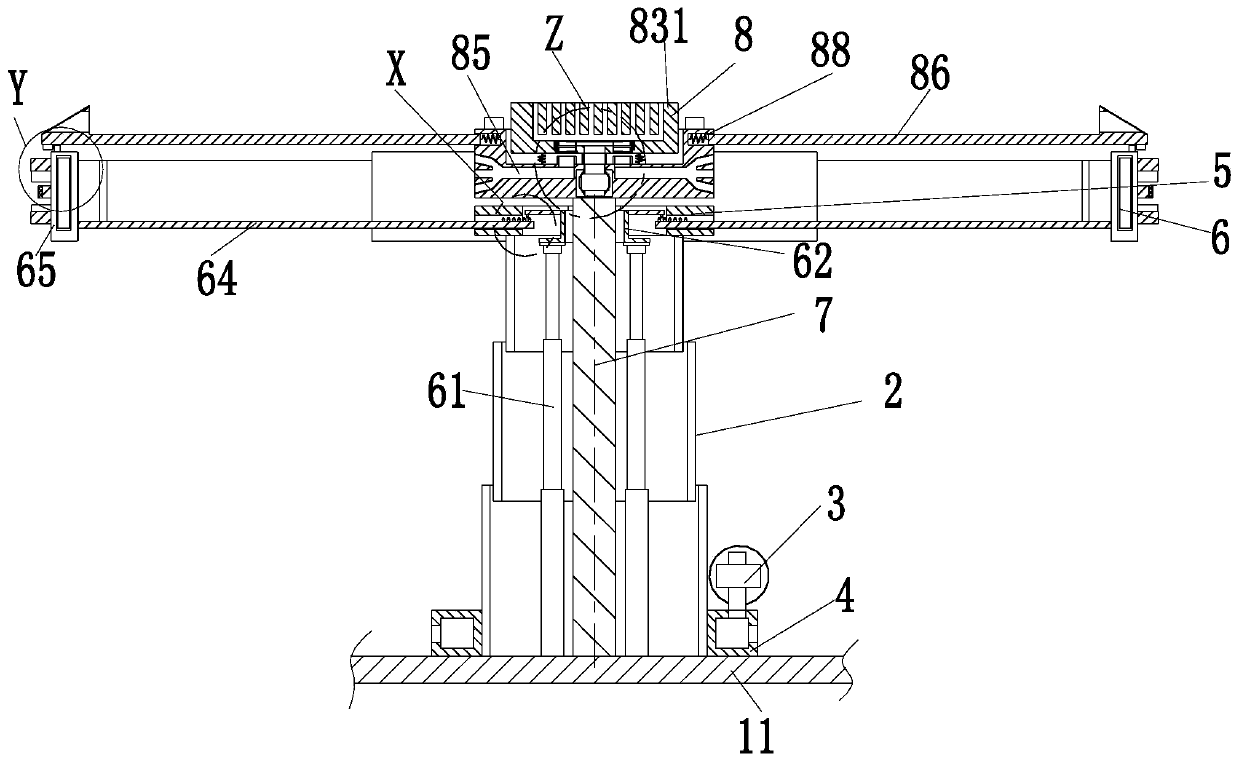

[0037] like Figure 1 to Figure 7 As shown, an internal processing device of a foundry flask includes a collection base 1, a telescopic cylinder 2, a working air pump 3, an annular frame 4, a working frame 5, a cleaning unit 6, a support column 7 and a support unit 8. The collection base A telescopic cylinder 2 is installed in the middle of the telescopic cylinder 2, an annular frame 4 is installed on the outer wall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap