A foot pedal automatic air return device

A pedal and automatic technology, applied in transportation and packaging, mechanical conveyors, conveyors, etc., can solve problems such as increasing the labor intensity of operators, reducing the speed of vehicle assembly, and affecting the production efficiency of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

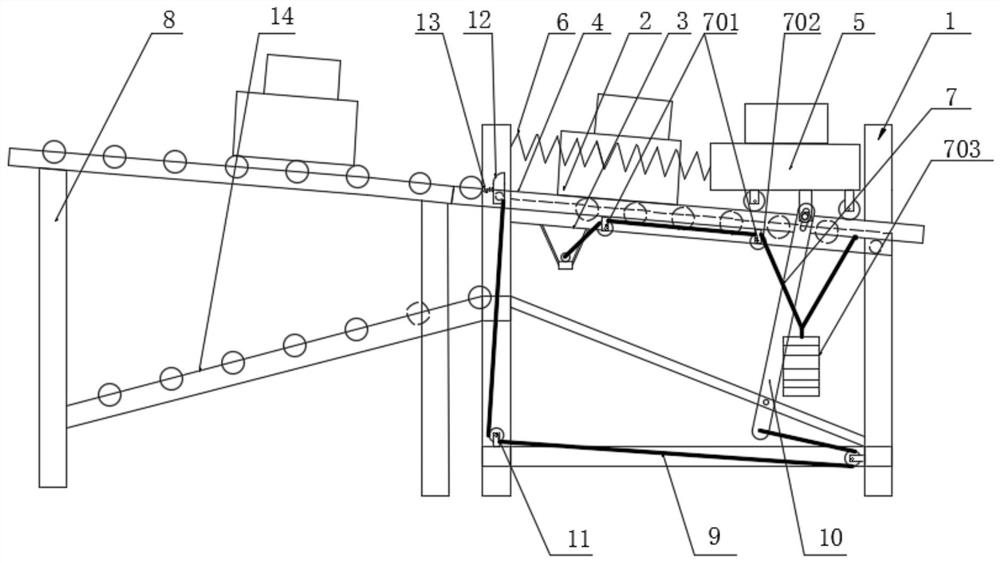

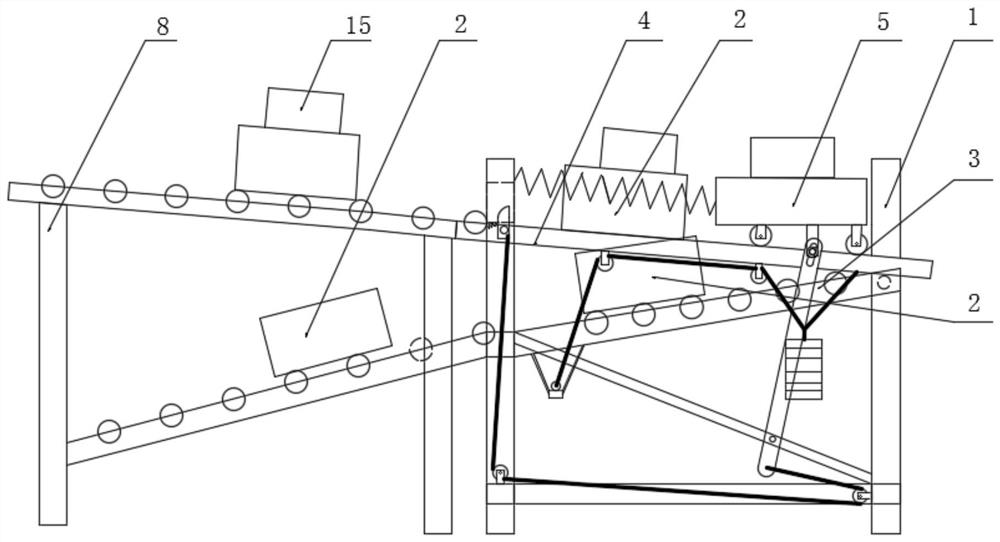

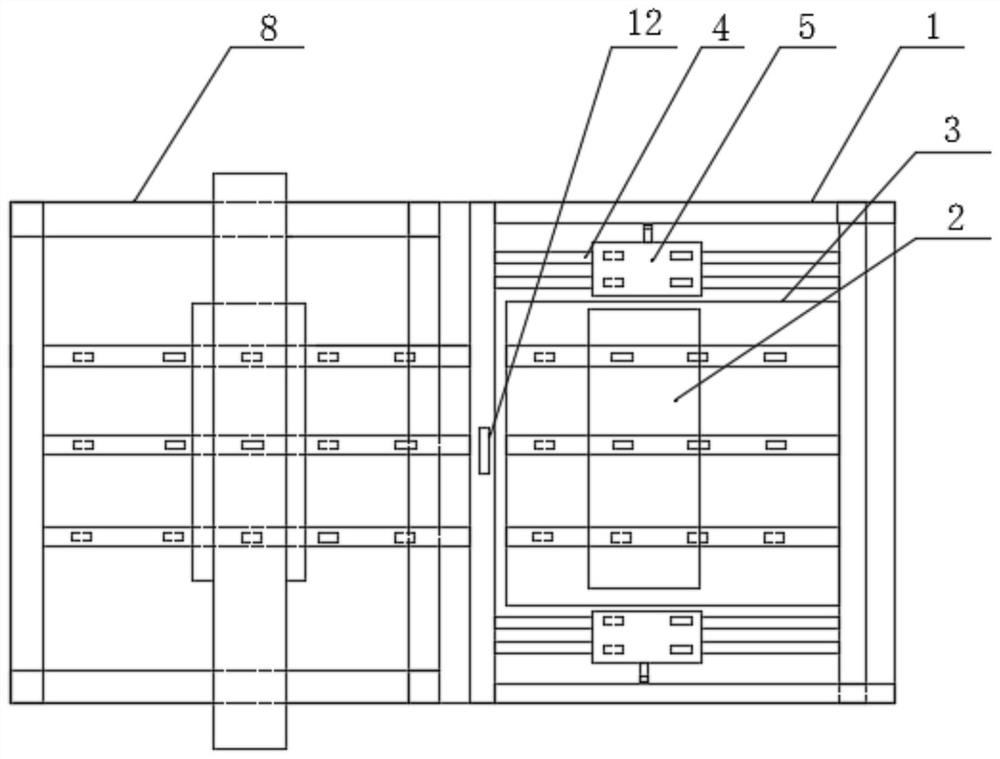

[0024] Such as Figure 1~3 As shown, a foot pedal 15 automatic air return device includes a first material conveying platform 1 and a pallet 2; Material plate 3; the conveying surface of the first material conveying platform 1 is set with a high left and a low right, and in the width direction of the first material conveying platform 1, support stations are provided on both sides of the right end, and between the support stations It is a cavity, and the distance in the width direction of the cavity is greater than the width of the pallet 2; the right end of the discharge plate 3 is hinged with the first material conveying platform 1; the discharge plate 3 is located below the cavity; the pallet 2 carries the pedal 15 Enter from the left side of the first material conveying platform 1: the tray 2 slides along the conveying surface of the first material conveying platform 1, the pedal 15 on the tray 2 slides along the top of the first material conveying platform 1 to the support...

Embodiment 2

[0028] Such as Figure 1~3 As shown, this embodiment is further limited on the basis of Embodiment 1: a foot pedal 15 automatic air return device, the top of the first material conveying platform 1 is provided with two slide rails 4 with a left high and a right low slope, the two The slide rails 4 are parallel to each other and arranged at intervals on the top of the first material conveying platform 1, two slide rails 4 are arranged on both sides of the unloading plate 3, and the projection on the vertical direction of the slide rails 4 is in line with the length direction of the first material conveying platform 1. Parallel; there is a trolley 5 on the slide rail 4, the trolley 5 provides a support station for the pedal 15, and can slide along the length direction of the slide rail 4, and the trolley 5 is always located on the slide rail 4 under the action of no external force Left end; the tray 2 carries the pedal 15 and enters from the left side of the first material conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com