Welding fixture sharing upper counterweight frame and lower counterweight frame

A welding tooling and counterweight frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as cumbersome, difficult to ensure accuracy, and production errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

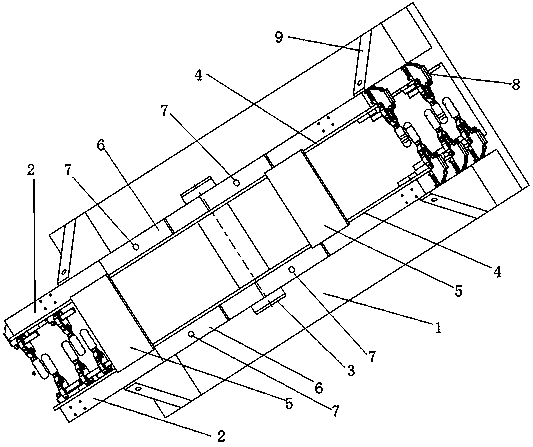

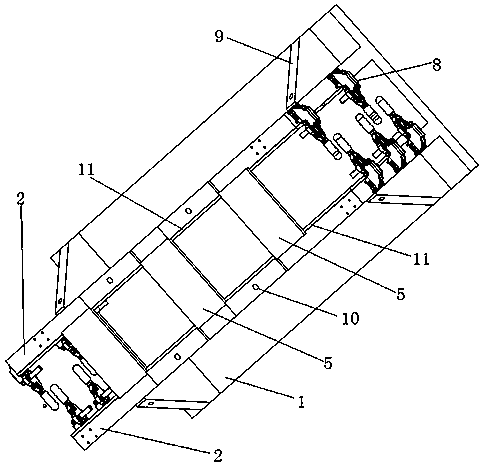

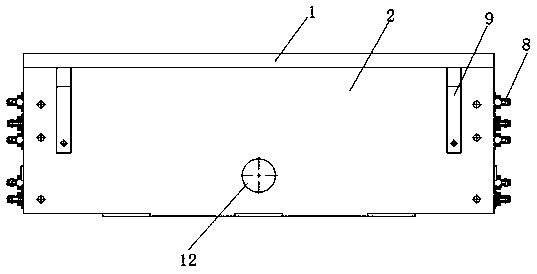

[0022] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings.

[0023] A welding tool shared by the upper and lower counterweight frames. The counterweight frame includes two types: an upper counterweight frame and a lower counterweight frame, which are installed on the upper and lower parts of the counterweight respectively. Both the upper counterweight frame and the lower counterweight frame include two It is a parallel and facing flat plate. The side of the flat plate is welded and connected by several connecting bars to form a U shape. The two flat plates of the lower counterweight frame are complete, and the two flat plates of the upper counterweight frame are pierced with round holes. The upper counterweight frame The plate width is greater than the plate width of the lower counterweight frame, and the plate length of the upper counterweight frame is equal to the plate length of the lower counterweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com