Welding positioning device for automobile sheet metal parts

A technology for automobile sheet metal parts, welding positioning, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of low welding positioning accuracy, and achieve the effects of improving welding quality, ensuring positioning and locking, and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

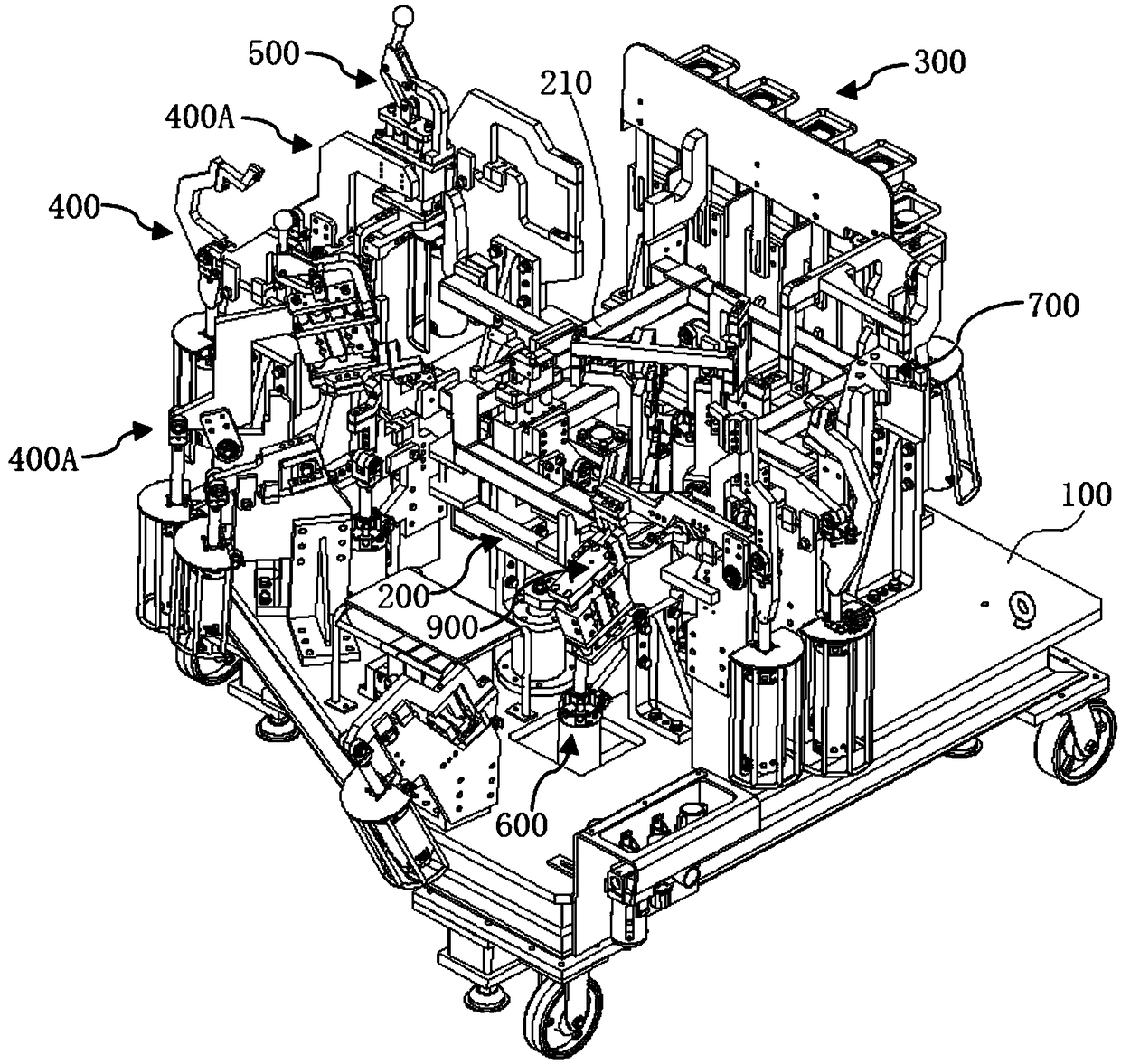

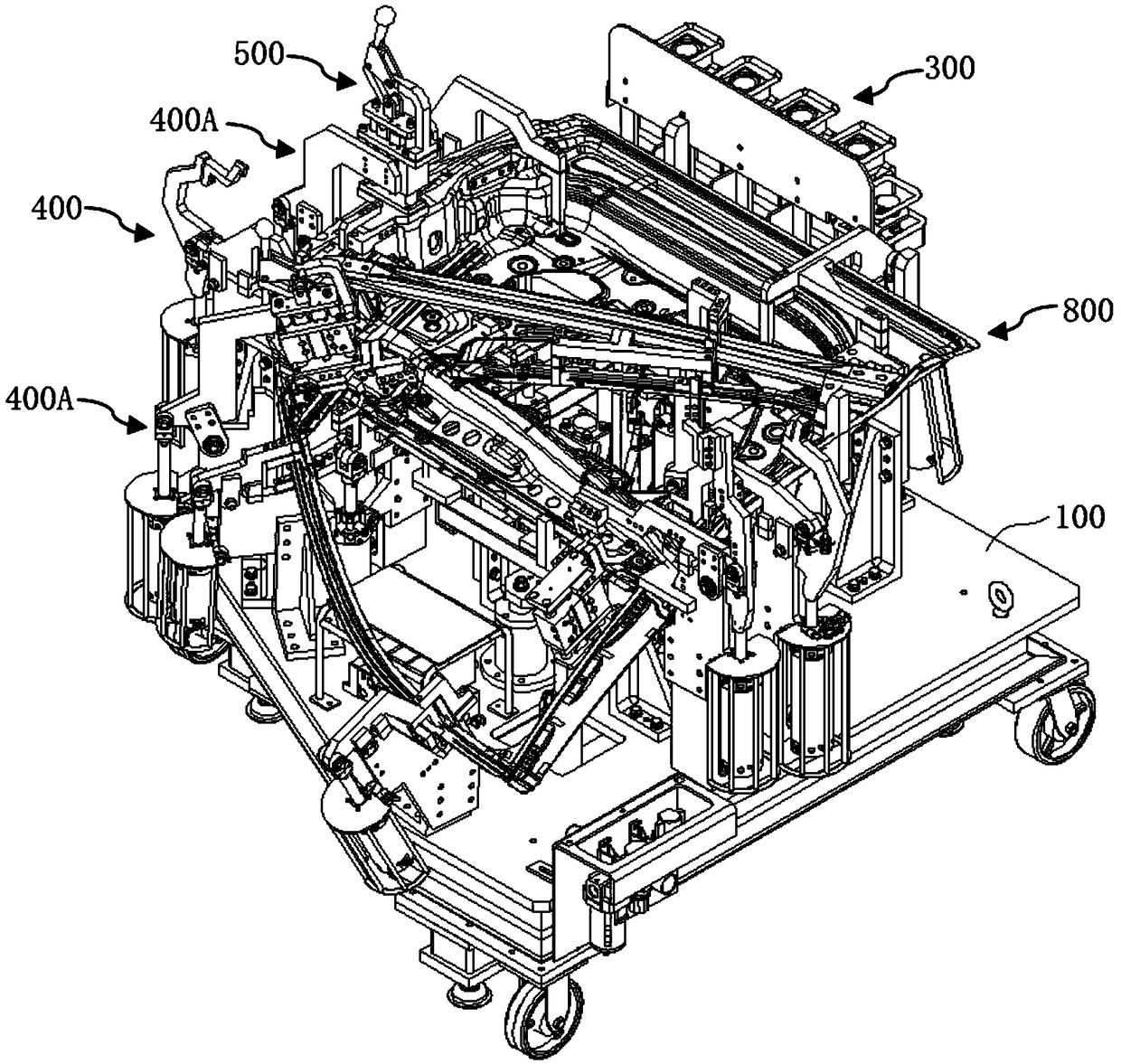

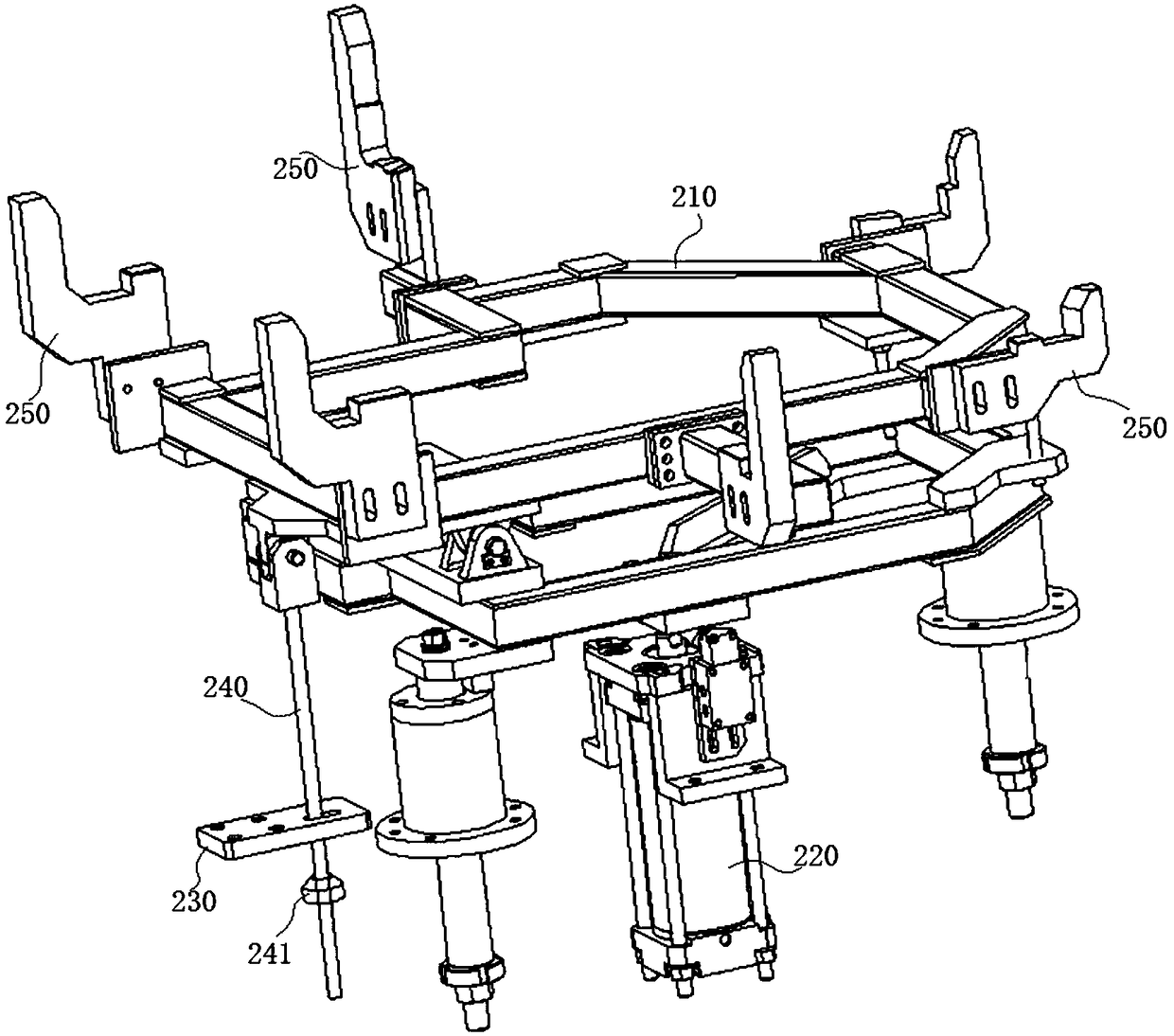

[0050] Such as Figure 1-Figure 11 As shown, a welding positioning device for automobile sheet metal parts in this embodiment includes a base 100, on which a placement platform 210 for supporting a workpiece 800 is arranged, and a plurality of placement platforms are arranged around the placement platform 210. The upper jaw unit 400 for locking the edge of the workpiece 800, and the upper hole jaw unit 400A for locking the hole position on the workpiece 800, wherein the upper hole positioning unit 500 is provided on the top of the upper hole jaw unit 400A, and the upper side Both the jaw unit 400 and the upper hole jaw unit 400A are disposed on the base 100 . During use, the workpiece 800 to be welded is placed on the placement platform 210, and the edge of the placement platform 210 is surrounded by a plurality of positioning plates 250, such as image 3 As shown, the positioning plate 250 can be set as an L-shaped plate structure, and the horizontal section and the vertical...

Embodiment 2

[0052] A kind of welding positioning device for automobile sheet metal parts of this embodiment, the basic structure is the same as embodiment 1, further, as Figure 5 and Figure 6 As shown, the upper hole jaw unit 400A in this embodiment includes an upper jaw cylinder 410, an upper jaw 440 is hinged on the top end of the telescopic rod of the upper jaw cylinder 410, and an upper connecting plate 420 is hinged on one side of the upper jaw cylinder 410 , the lower part of the upper jaw 440 is hinged with the upper connecting plate 420 through the upper hinge plate 430, and the top of the upper jaw 440 is provided with an upper hole positioning unit 500. Specifically, the lower part of the upper jaw 440 is fixedly connected with the upper hinge plate 430, and the upper hinge plate 430 is hinged to the upper connecting plate 420 , and ribs are fixed on both sides of the upper connecting plate 420 to strengthen the structural strength and stability, and the ribs are fixed on the ...

Embodiment 3

[0057] A welding positioning device for automobile sheet metal parts in this embodiment has the same basic structure as in Embodiment 2. Further, an upper movable plate 540 is arranged above the upper fixing seat 510 in this embodiment, and the upper movable plate 540 is symmetrical on both sides. An upper guide post 512 is provided, and the upper guide post 512 passes through the upper fixing seat 510 and is connected with the upper lifting plate 530 . When the upper telescopic rod 511 drives the upper lifting plate 530 to move up and down, the upper guide posts 512 on both sides move up and down in the upper fixed seat 510, and drive the upper movable plate 540 to lift up and down. The lifting motion of the upper positioning pin 532 is guided and positioned to ensure the accuracy and stability of the lifting direction of the upper positioning pin 532, and the positioning accuracy of the hole is further guaranteed to be improved.

[0058] Further, as Figure 7 As shown, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com