Gravity center lifting crane anti-sway device

An anti-sway device and lifting technology, which is applied in the direction of cranes, trolley cranes, transportation and packaging, etc., can solve the problem that heavy objects are easy to shake, and achieve a good anti-sway effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

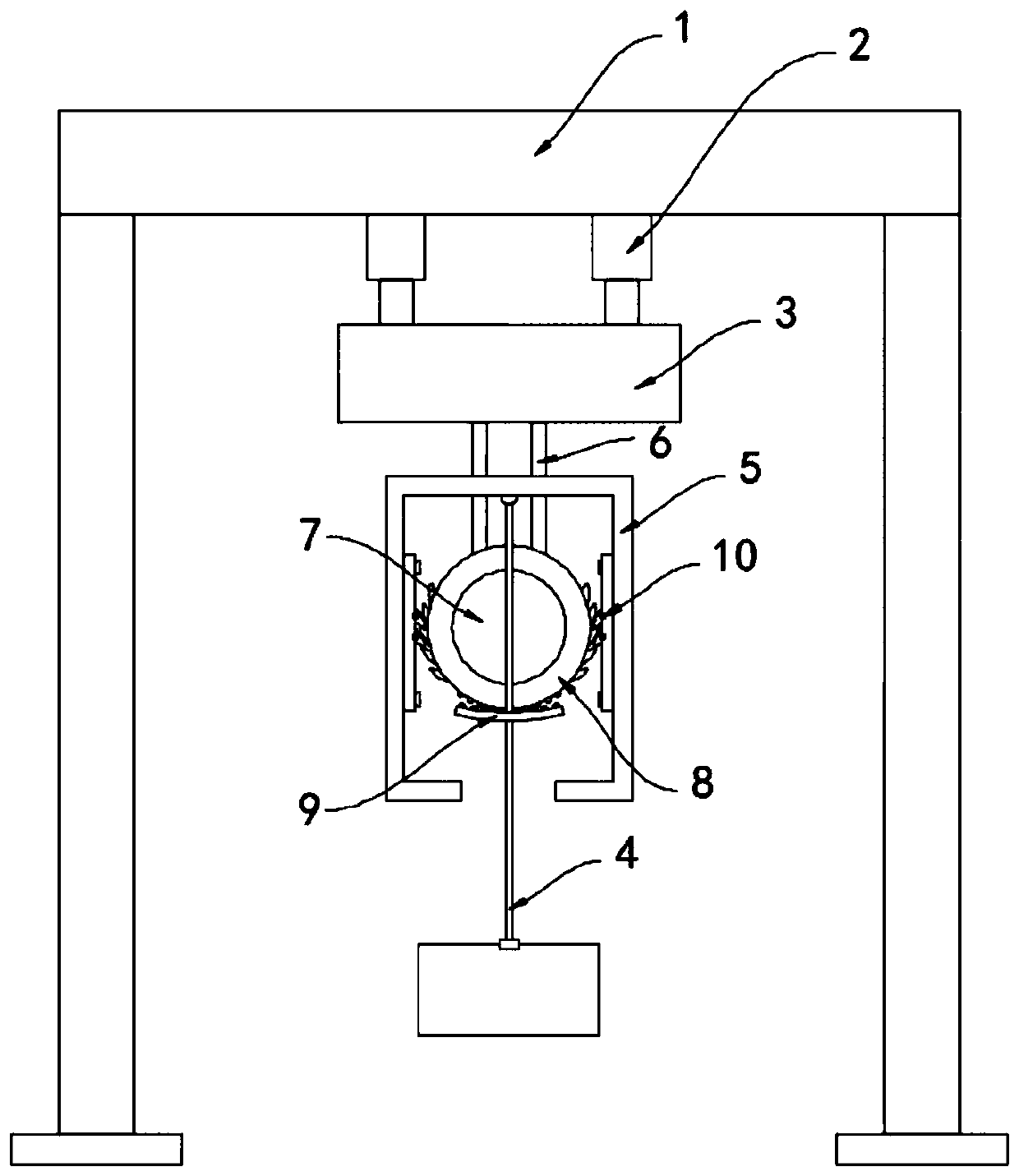

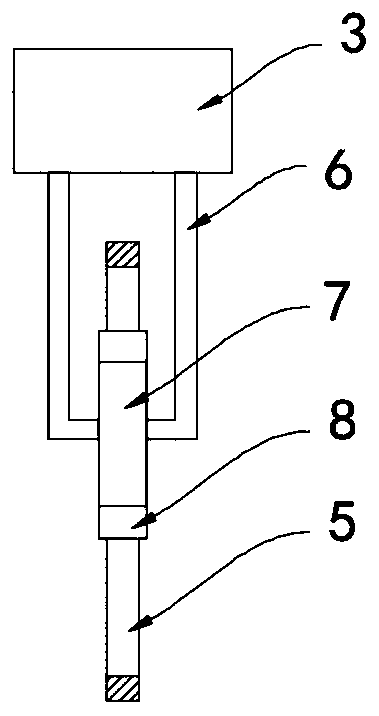

[0019] Such as Figure 1-2 As shown, a center of gravity lifting type crane anti-sway device includes a support frame 1, a lifting mechanism 2, a running trolley 3 and a sling 4, an anti-sway frame 5 is provided under the running trolley 3, and the upper end of the sling 4 is connected to the anti-sway The inner top surface of the rocking frame body 5 is fixedly connected, and the lower end of the running trolley 3 is fixedly connected with two L-shaped connecting rods 6, and a fixed wheel 7 is fixedly installed between the two L-shaped connecting rods 6, and the fixed wheel 7 is located at the In the rocking frame body 5 and parallel to the anti-rolling frame body 5, a rotating ring 8 is connected to the outer ring side wall of the fixed wheel disc 7, and balls are arranged between the fixed wheel disc 7 and the rotating ring 8, so that the sliding friction becomes Rolling friction reduces friction consumption and prolongs its service life. The lower end of the rotating ring ...

Embodiment 2

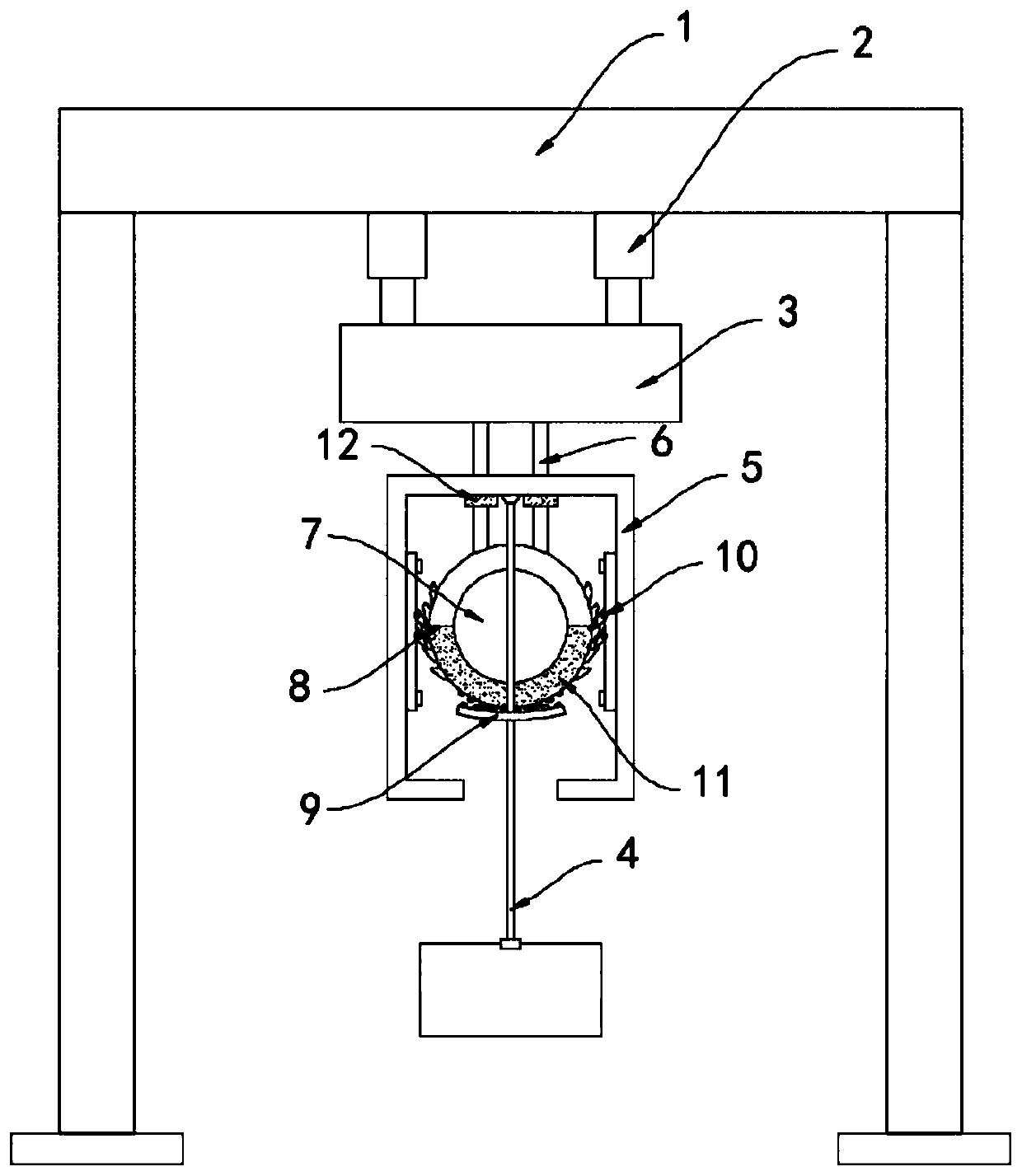

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the rotating ring 8 is composed of two semi-circular rings 11, the semi-circular ring 11 located below is made of magnetic material, and the inner top surface of the anti-rolling frame 5 A permanent magnet block 12 is fixedly installed, and the same polarity repels each other between the permanent magnet block 12 and the semi-circular ring 11 .

[0024] In this embodiment, when the sling 4 and the heavy object are not swinging, the permanent magnet block 12 is far away from the magnetic semi-circular ring 11, and when the heavy object drives the sling 4 to swing, it drives the rotating ring 8 to rotate, The magnetic semi-circular ring 11 located at the bottom rotates to a higher position and approaches the direction of the permanent magnet block 12, that is, when the sling 4 swings, it needs to overcome the repulsive force between the permanent magnetic block 12 and the semi-circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com