Five-axis linkage point butt joint sock turning device

A five-axis linkage and sock machine technology, which is applied in textiles and papermaking, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of insufficient sock suction, inability to suck socks, and inability to maximize the suction of socks, so as to ensure precise suction , Improve production efficiency, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

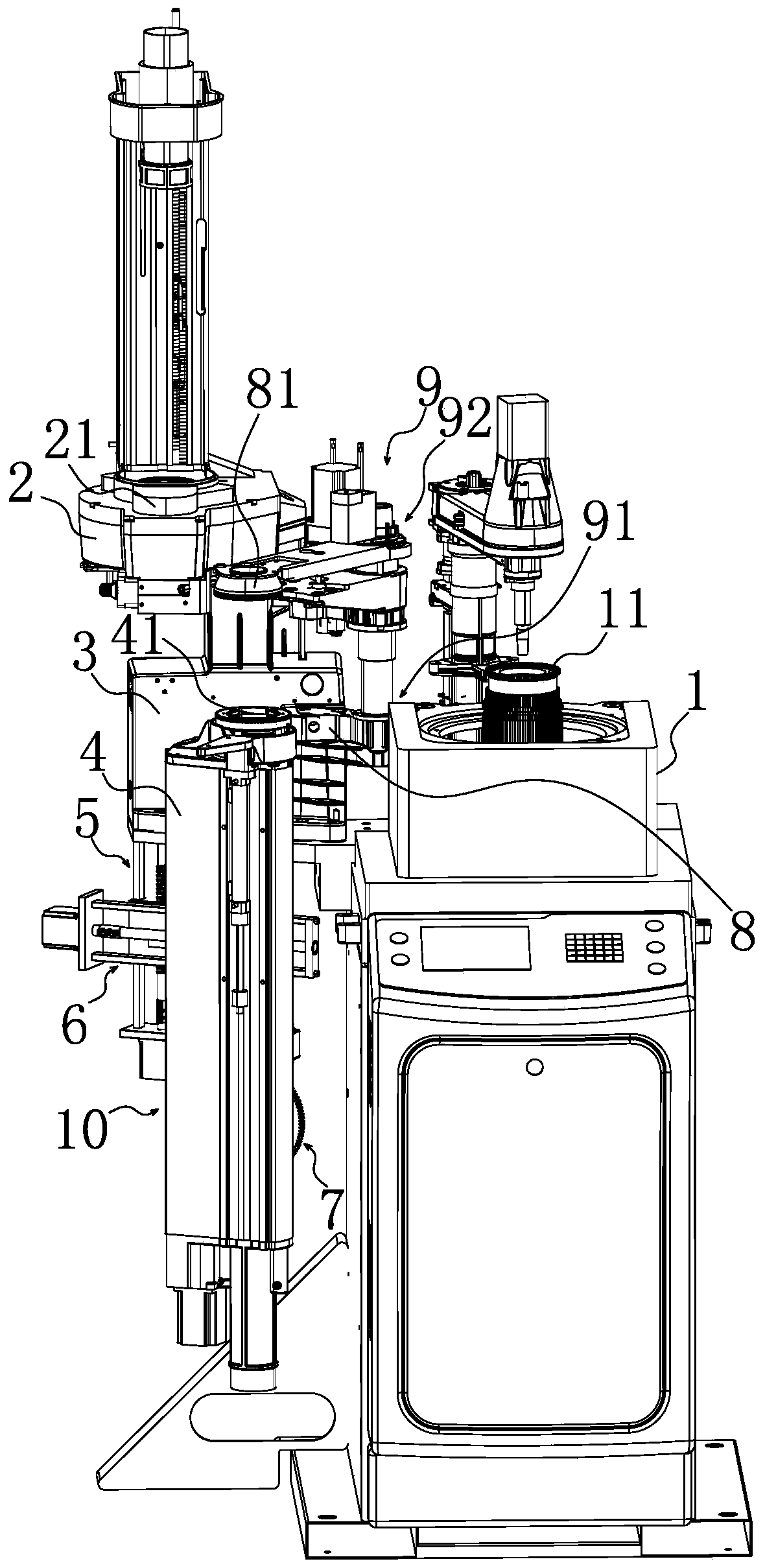

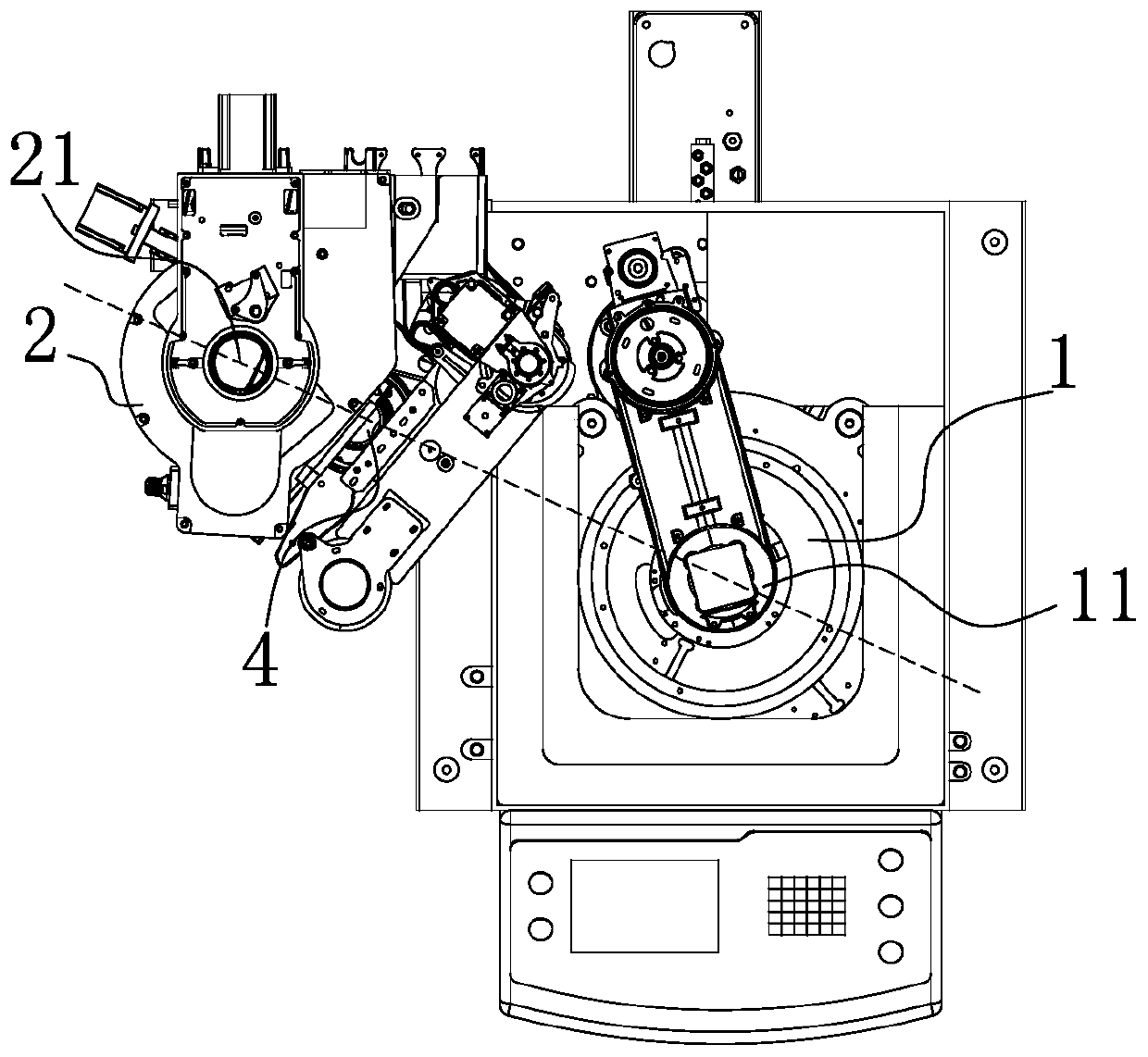

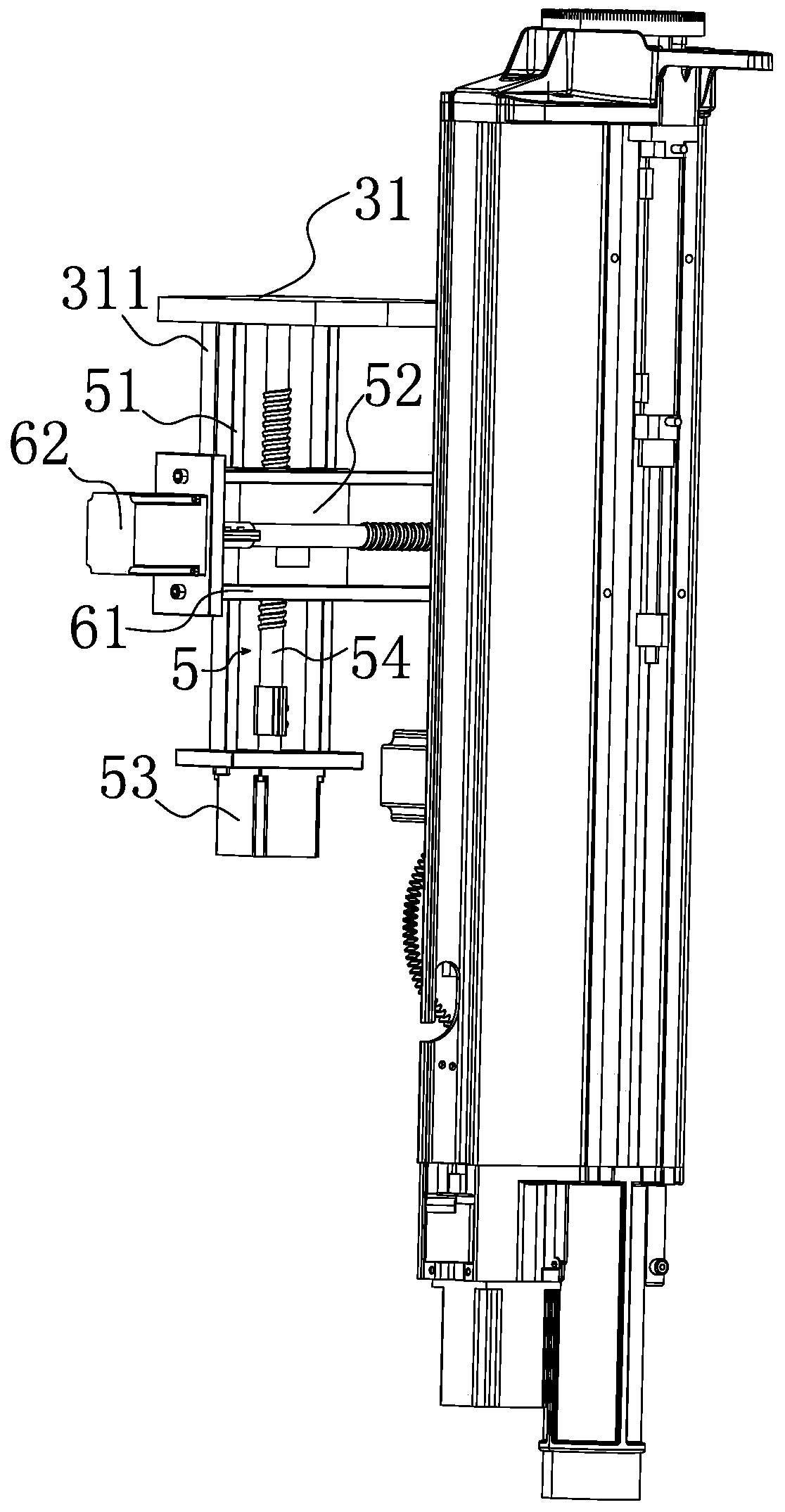

[0028] Such as Figure 1-2 As shown, the five-axis linkage point butt joint sock turning device is arranged between the sock knitting mechanism 1 and the sewing mechanism 2, and includes a sock taking frame body 8 which is movably arranged on the sock machine frame 3 and has a sock taking part 81. Between the sock frame body 8 and the hosiery machine frame 3, there is a device that can drive the sock frame body 8 to move up and down in the vertical direction and drive the sock frame body 8 to swing circumferentially in the horizontal direction so that the sock frame body 81 moves to the sock knitting mechanism. 1 directly above or directly below the sewing mechanism 2, the sock-taking drive mechanism 9, one side of the sock machine frame 3 is movable and provided with a sock-absorbing cylinder 4 arranged in the vertical direction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com