Toy driving system and toy car

A technology for a drive system and a toy, applied in the field of a toy drive system and a toy car, can solve the problems of unfavorable toy car manufacturing, structural complexity of toy cars, and high cost of toy car manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

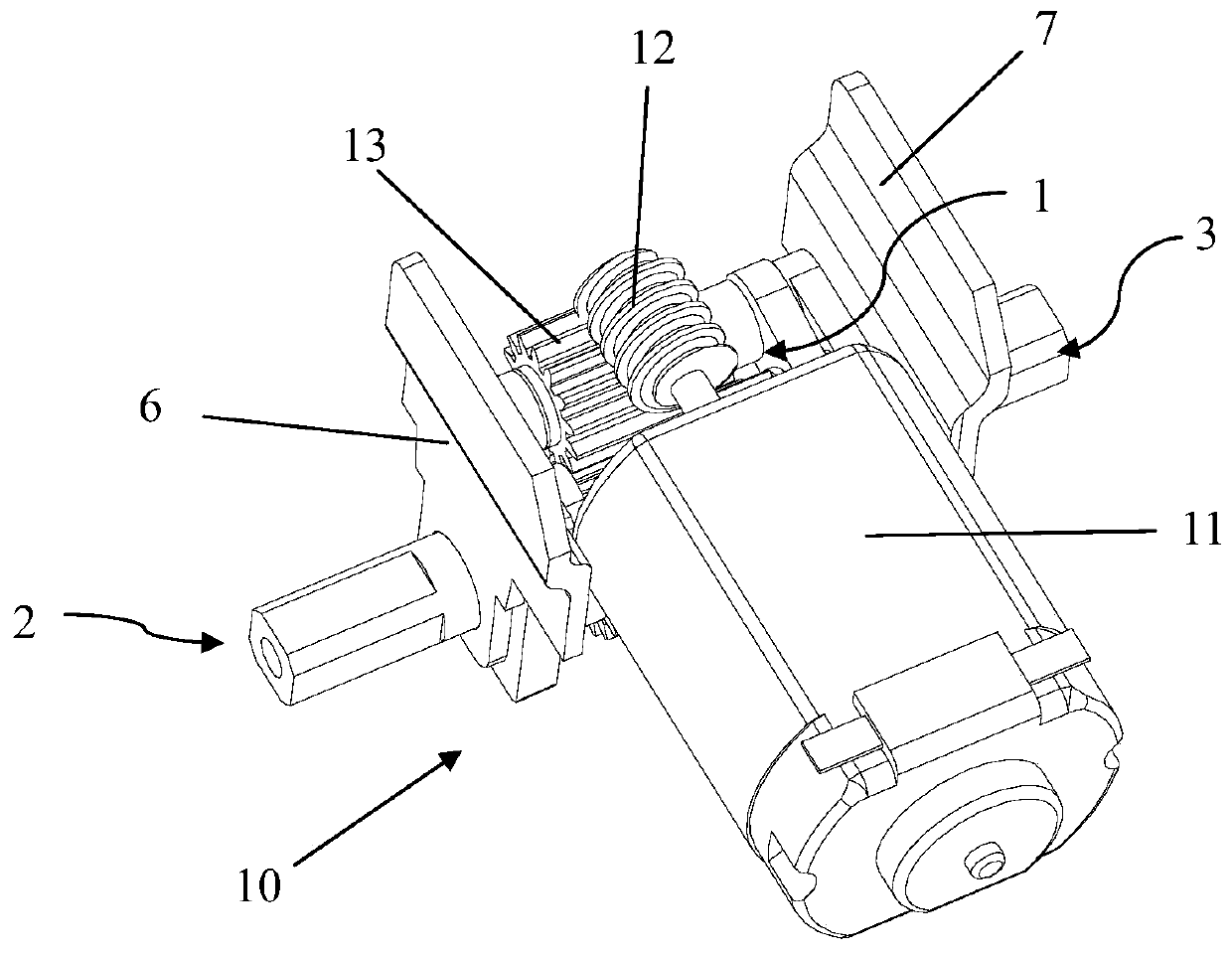

[0051] like Figure 3-10 Shown is a schematic diagram of the driving system of the toy in Embodiment 1 of the present invention.

[0052] like Image 6 As shown, the toy driving system 10 includes a power unit 1, a first output mechanism 2 and a second output mechanism 3, and also includes a clutch transmission mechanism 4 and a one-way transmission mechanism 5. The connection between the first output mechanism 2 and the second output mechanism 3 A one-way transmission mechanism 5 is connected between them, and the one-way transmission mechanism 5 transmits the power from the first output mechanism 2 to the second output mechanism 3 in one direction, and the clutch transmission mechanism 4 is connected between the power unit 1 and the second output mechanism 2;

[0053] When the power unit 1 rotates in the first direction, the power unit 1 drives the first output mechanism 2 to rotate, and the power unit 1 drives the second output mechanism 3 to rotate through the clutch tran...

Embodiment 2

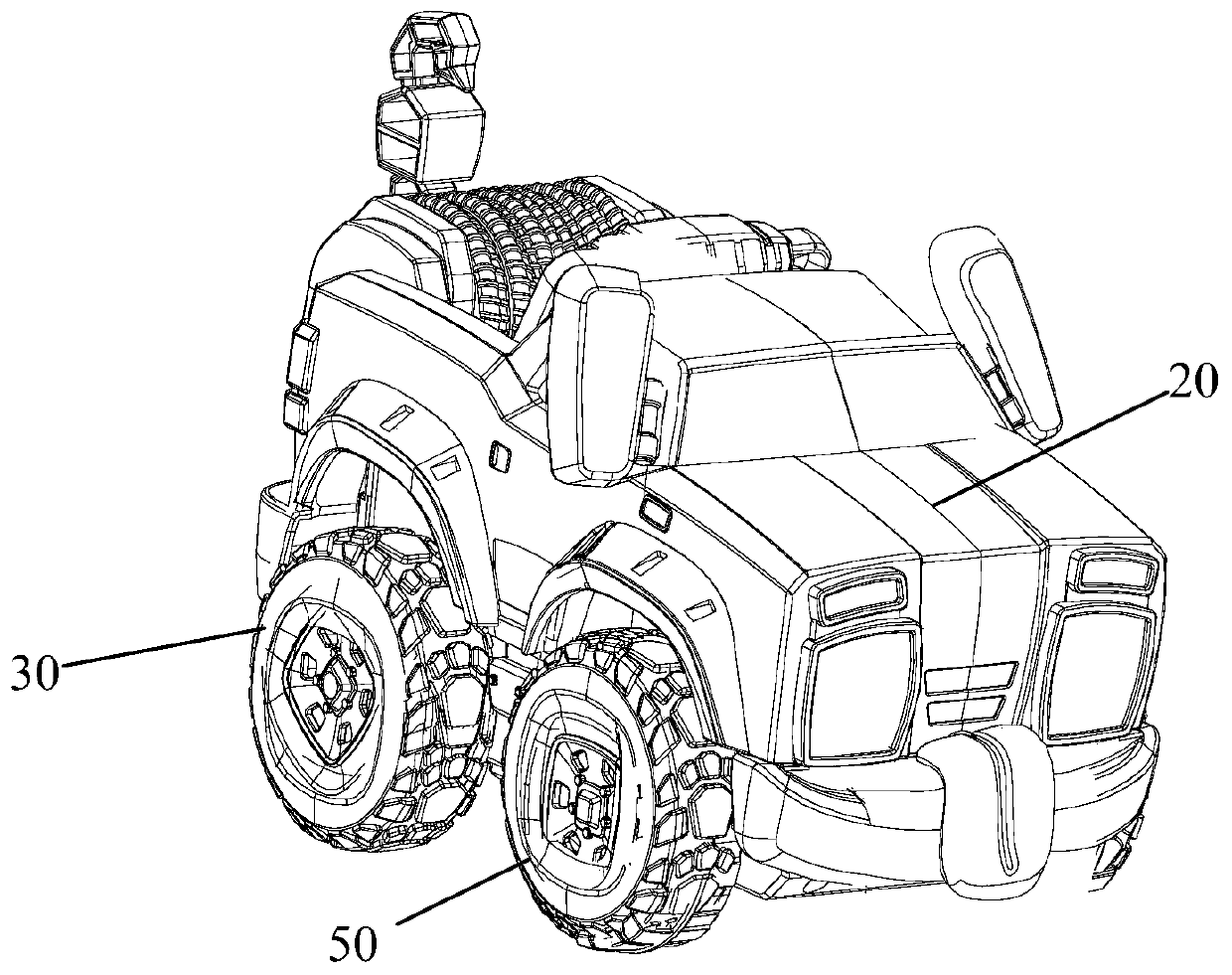

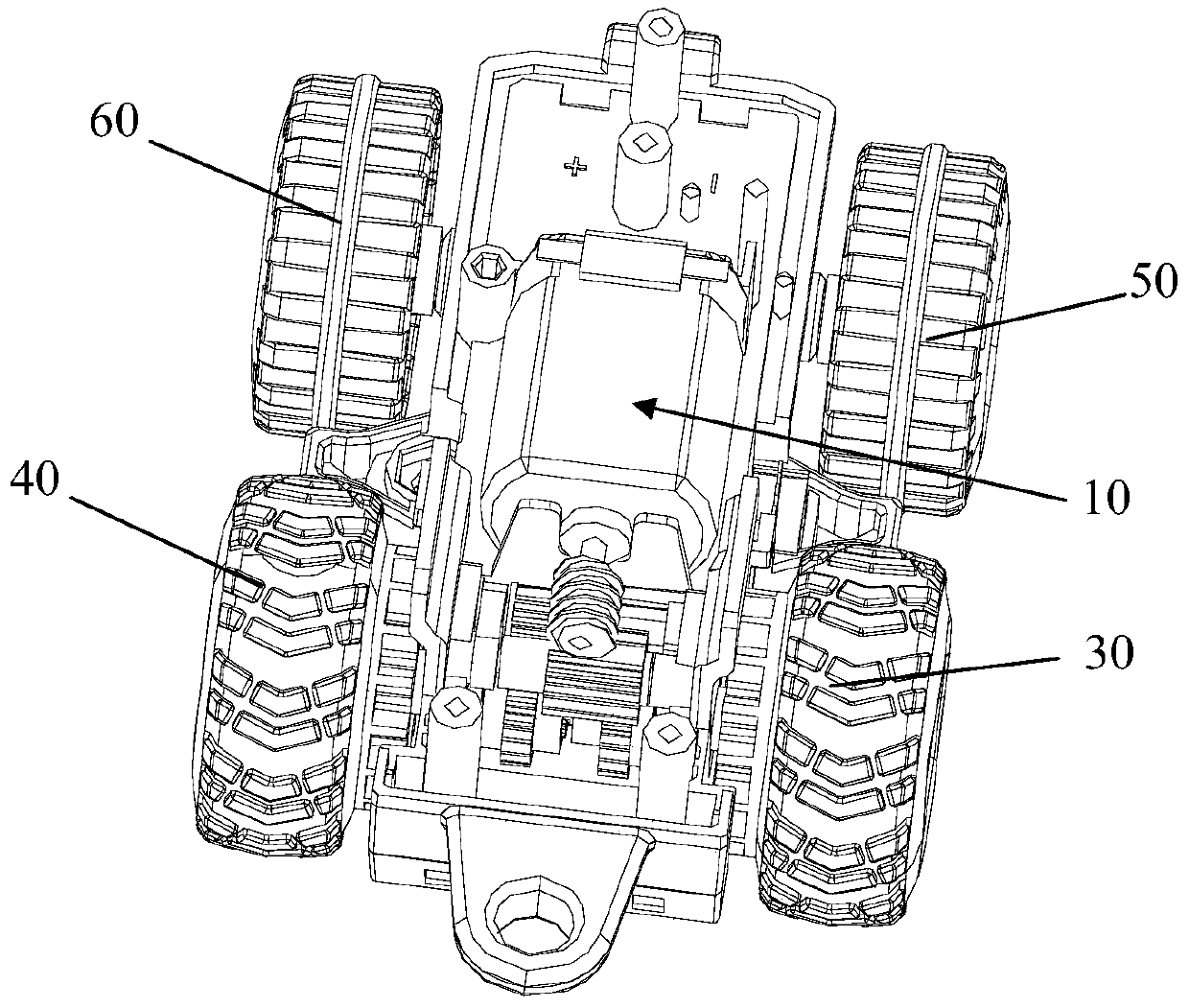

[0124] like Figure 1-2 As shown, the toy car includes a car body 20, a first driving wheel 30 and a second driving wheel 40, and also includes a toy driving system 10. The first output mechanism 2 is connected to the first driving wheel 30, and the second output mechanism 3 is connected to the second driving wheel 40. The drive wheel 40 is connected.

[0125] Wherein, the first driving wheel 30 and the second driving wheel 40 are located at the rear of the car, and the toy car also includes a front right wheel 50 and a front left wheel 60 at the front of the car.

[0126] The toy drive system 10 is installed in the vehicle body 20 and is located near the rear of the vehicle. Wherein, the first output mechanism 2 is connected with the first driving wheel 30 , and the second output mechanism 3 is connected with the second driving wheel 40 .

[0127] When the first output mechanism 2 and the second output mechanism 3 rotate in the same direction, the first driving wheel 30 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com