Composite mode type linear ultrasonic motor based on end oblique piezoelectric ceramics

An ultrasonic motor and electric ceramic technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. It can solve the problems of directional or bidirectional operation, complex structure, etc., to achieve the effect of convenient forward and reverse commutation operation and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

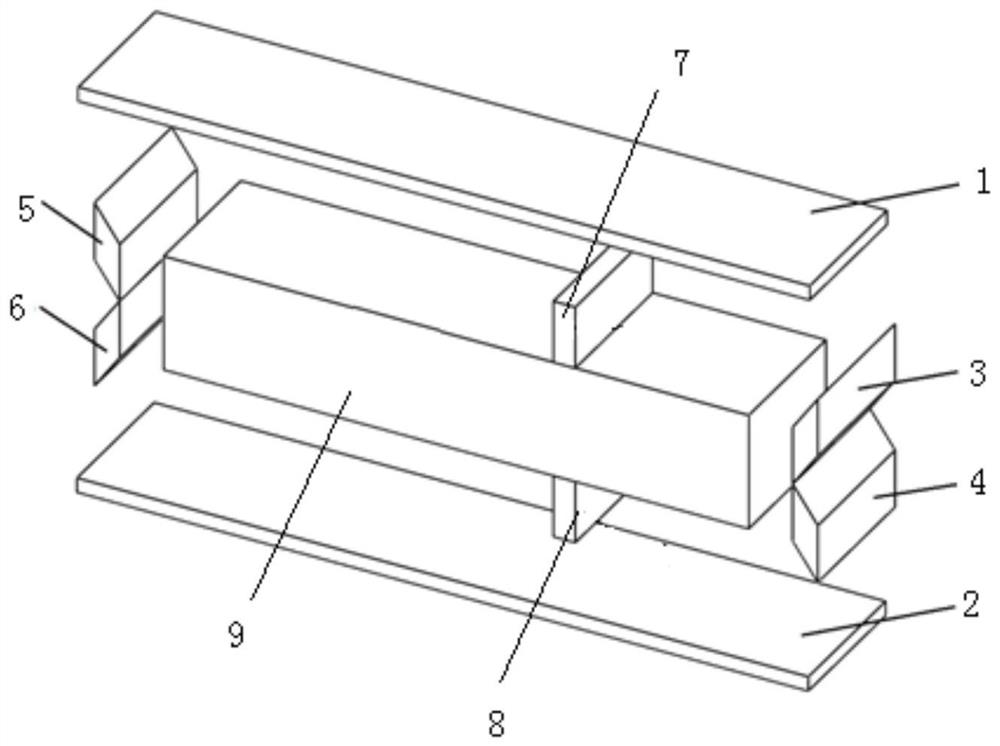

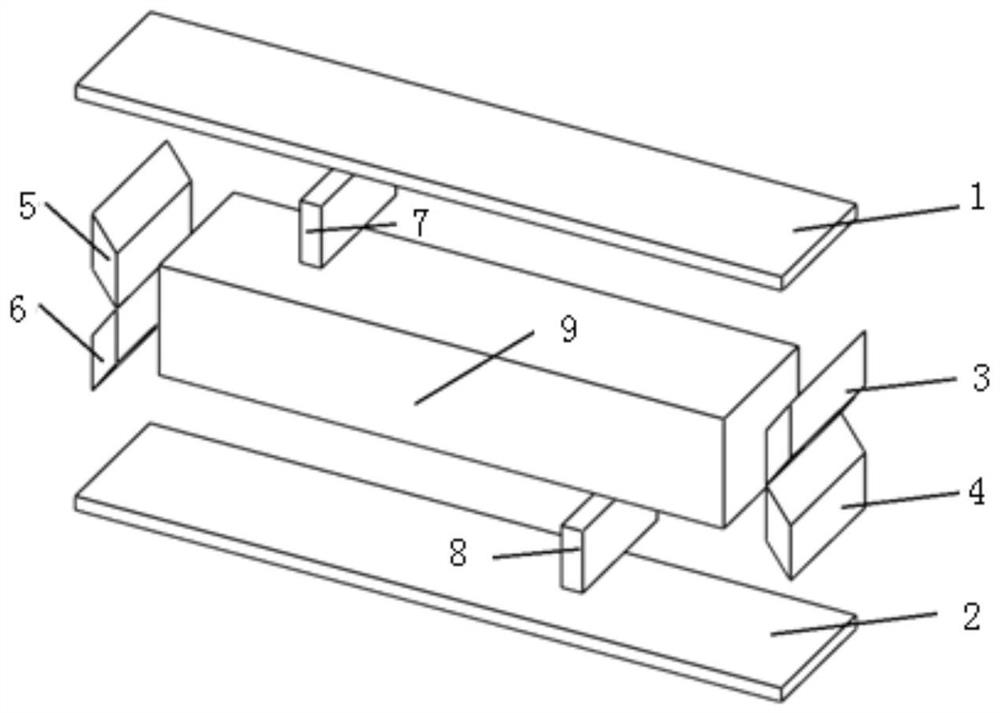

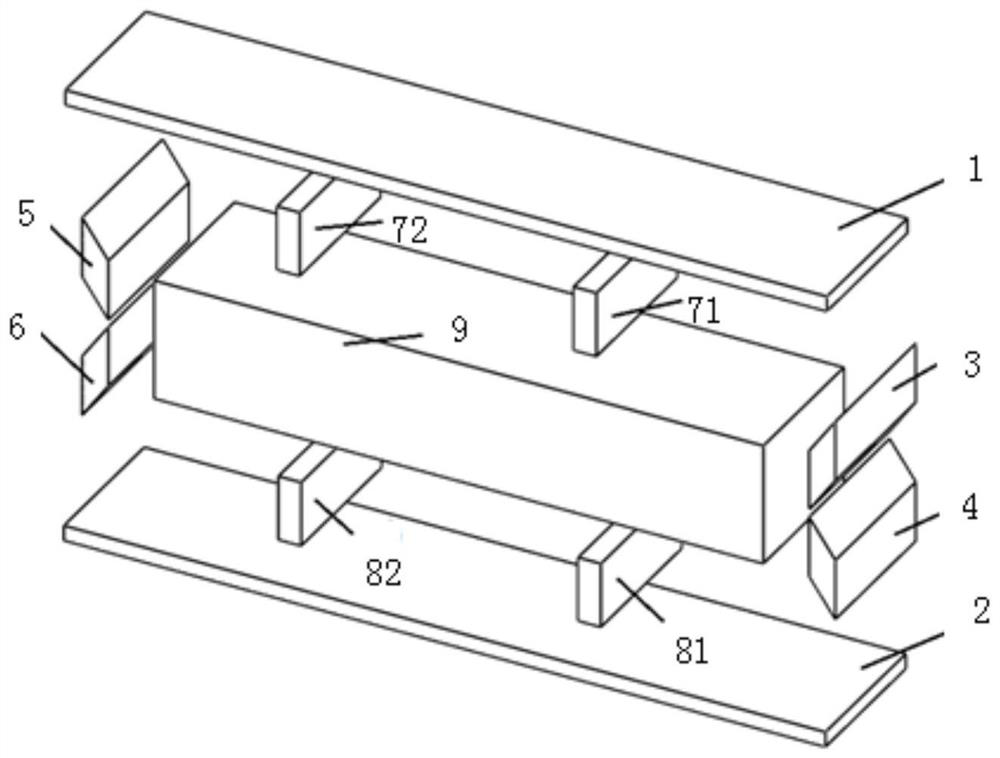

[0043] A compound-mode linear ultrasonic motor based on end-crank piezoelectric ceramics. The motor works in the longitudinal-torsional vibration mode, which includes a stator unit and a mover unit. The mover unit includes an upper mover 1 and a lower mover 2. The stator The unit is set between the upper mover 1 and the lower mover 2. The stator unit includes a metal elastic body 9, an upper drive foot 7, a lower drive foot 8 and an end inclined piezoelectric ceramic. The upper drive foot 7 is set on the metal elastic body 9. On the surface, the lower driving foot 8 is set on the lower surface of the metal elastic body 9, the upper mover 1 is set above the upper driving foot 7, the lower mover 2 is set below the lower driving foot 8, and the end oblique piezoelectric ceramics include the right upper oblique piezoelectric ceramics. Ceramic 3, right lower oblique piezoelectric ceramic 4, left upper oblique piezoelectric ceramic 5 and left lower oblique piezoelectric ceramic 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com