Water relief groove to prevent cavitation of opposite refiner plate

一种精磨机、磨机的技术,应用在纸浆打浆/精浆方法、纺织品和造纸、造纸等方向,能够解决精磨机板节段使用寿命减少等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

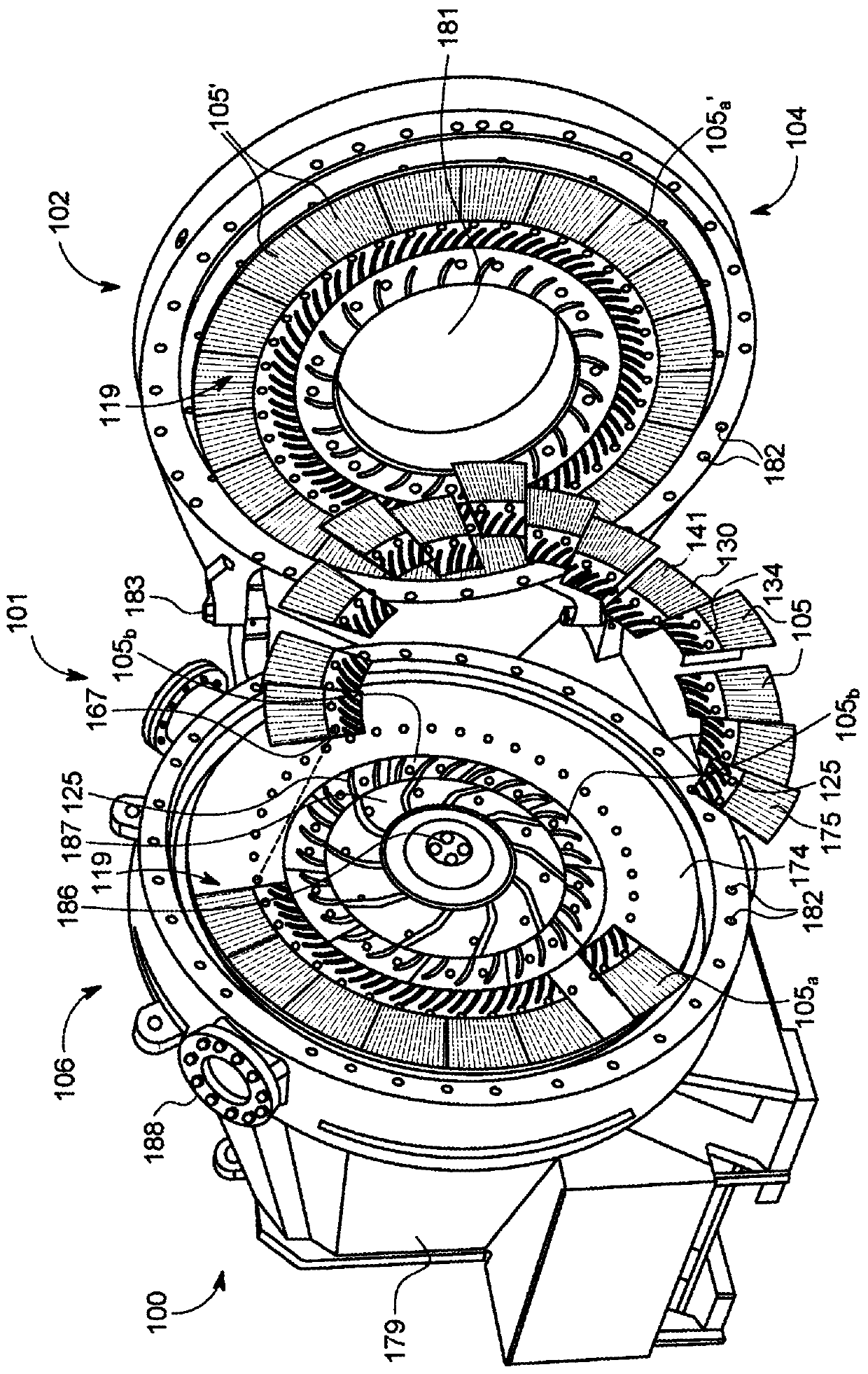

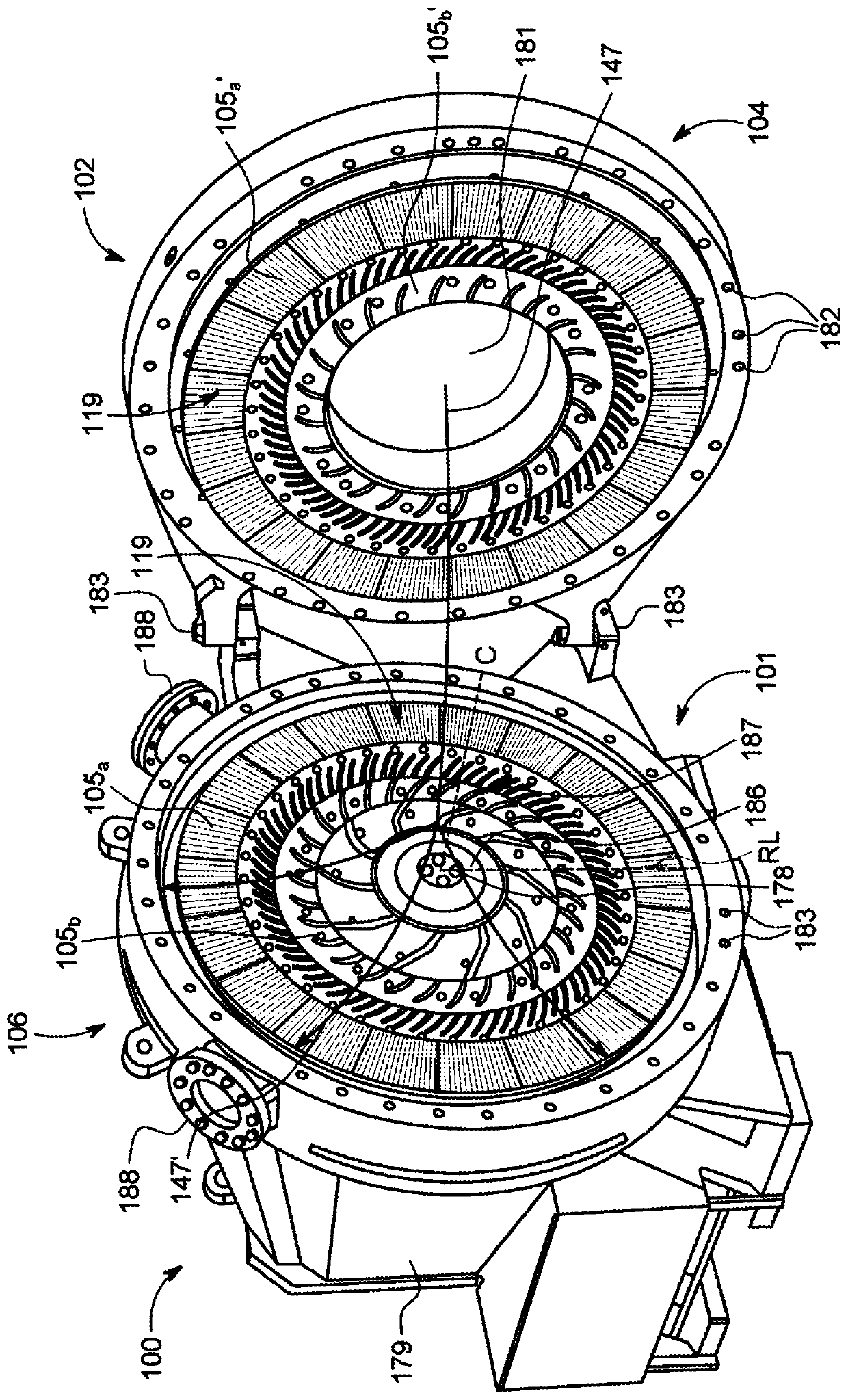

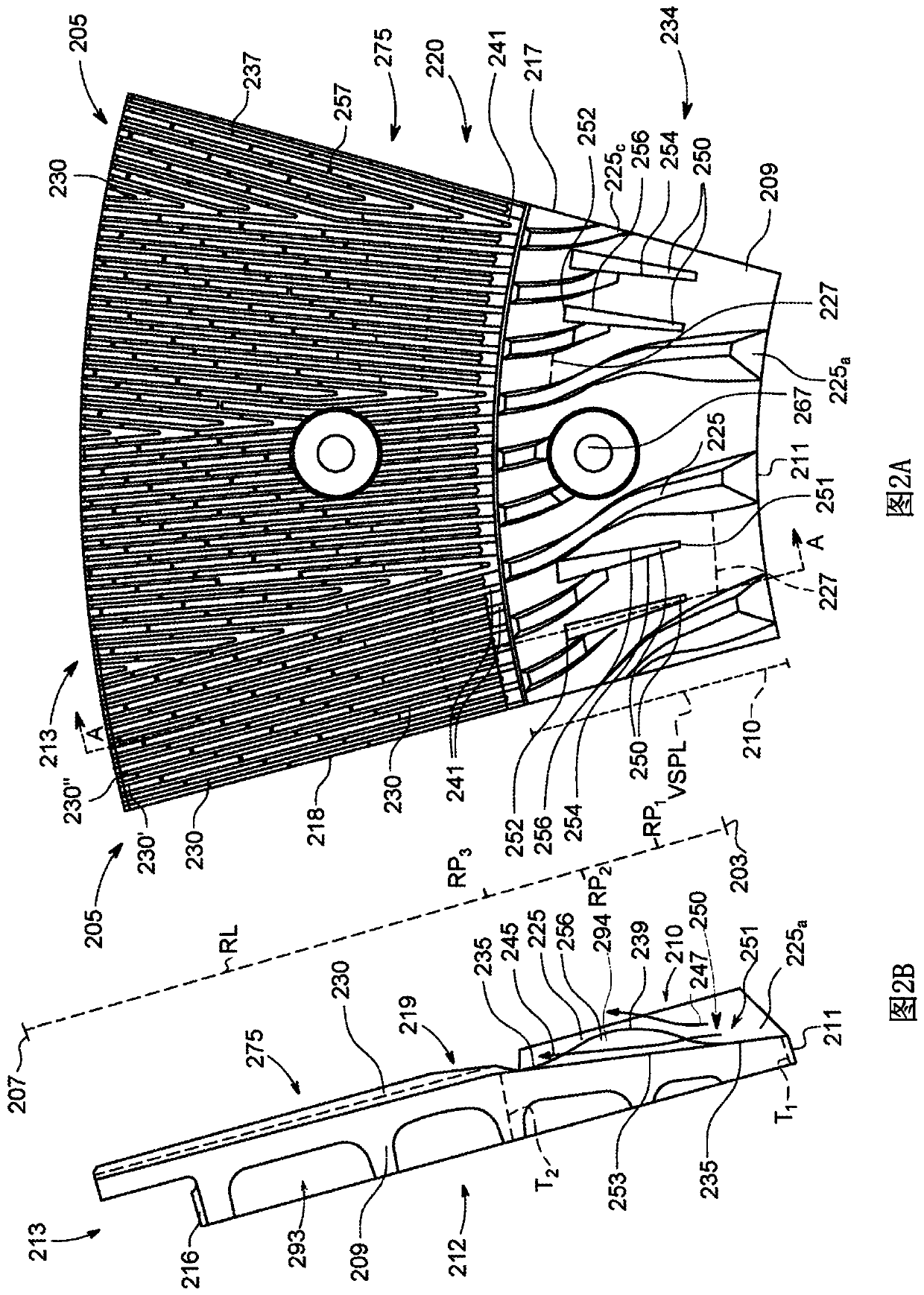

[0034] The following detailed description of the preferred embodiments is presented for purposes of illustration and description only, and is not intended to be exhaustive or to limit the scope and spirit of the invention. The embodiment was chosen and described in order to best explain the principles of the invention and its practical application. Those of ordinary skill in the art will recognize that many changes can be made to the invention disclosed in the specification without departing from the scope and spirit of the invention.

[0035]Unless otherwise indicated, like reference numerals indicate corresponding parts throughout the several views. Although the drawings represent embodiments of various features and components according to the present disclosure, the drawings are not necessarily to scale and some features may be exaggerated to better illustrate embodiments of the present disclosure, and such illustrations should not be construed as limiting the scope of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com