Method for preventing local cavitation of flow passage component of water turbine

A technology for flow-passing components and water turbines, applied in anti-corrosion coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems that thermal stress cannot be completely eliminated, increase the maintenance cost of power stations, and do not have treatment conditions, etc., to achieve perfection The effect of equipment management system, improvement of safe and stable operation level, excellent tensile and compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Select the smear material, select the repair agent for metal repair, select the curing agent for bonding, the curing agent is 200 low molecular weight polyamide, and the amine value is 230~260mg KOH / g;

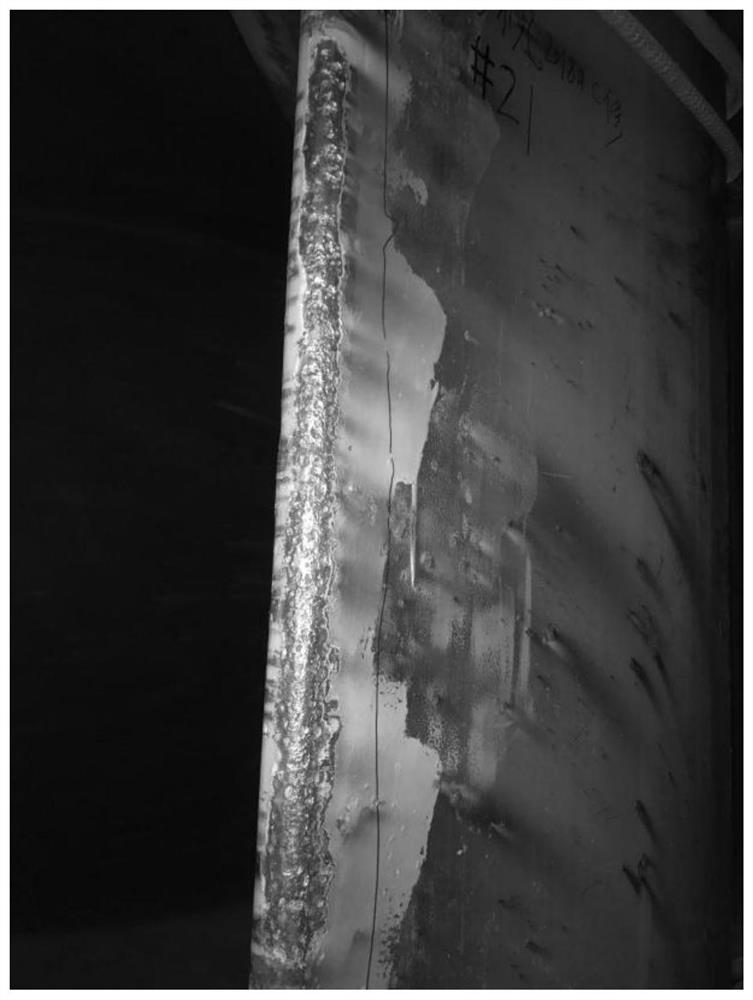

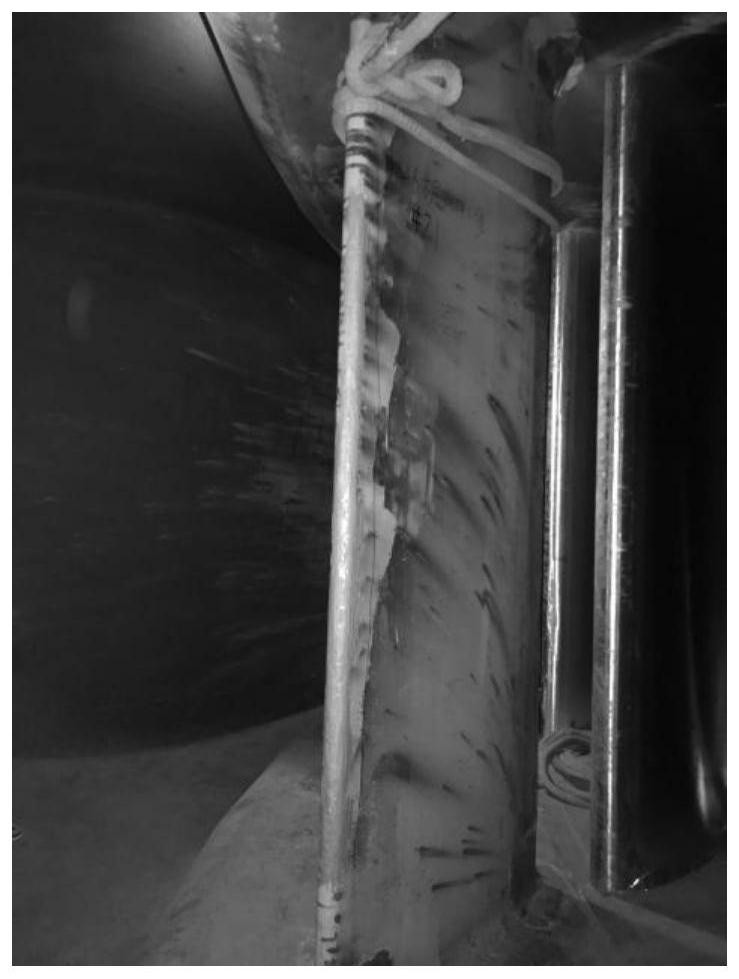

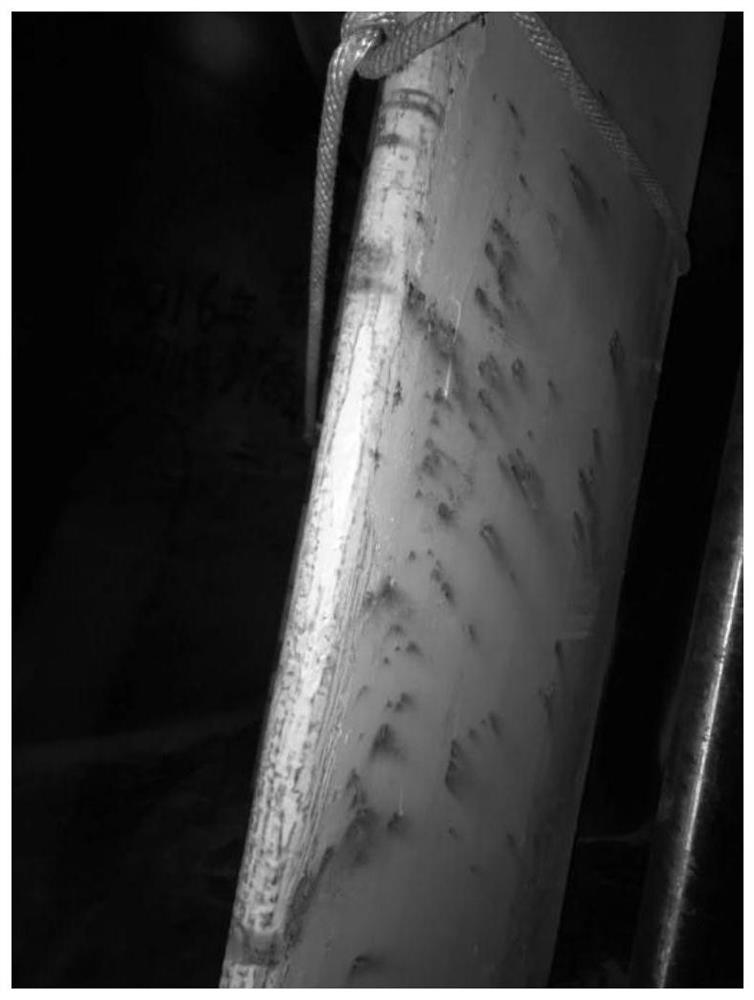

[0057] (2) Surface treatment, use a polishing tool to polish the cavitation part of the flow-passing part, remove all impurities in the cavitation pit with acetone, and reveal the metallic luster, clean the polished surface with a detergent, and leave no dust and impurities on the surface, and dry the surface;

[0058] (3) Prepare the mixing agent, mix the repairing agent in step 1 with the curing agent, the weight ratio of the repairing agent and the curing agent is 1:0.14, use a stirring and rolling device to prepare the The mixture is continuously stirred and rolled in one direction, so that the streaks of different colors of the repairing agent and curing agent components in the mixture completely disappear until a smooth mixture with the same color appears, and...

Embodiment 2

[0070] (1) Select the smear material, select the repair agent for metal repair, select the curing agent for bonding, the curing agent is 200 low molecular weight polyamide, and the amine value is 230~260mg KOH / g;

[0071] (2) Surface treatment, use a polishing tool to polish the cavitation part of the flow-passing part, remove all impurities in the cavitation pit with acetone, and reveal the metallic luster, clean the polished surface with a detergent, and leave no dust and impurities on the surface, and dry the surface;

[0072] (3) Prepare the mixing agent, mix the repairing agent in step 1 with the curing agent, the weight ratio of the repairing agent and the curing agent is 10:1.2, use a stirring and rolling device to prepare the The mixture is continuously stirred and rolled in one direction, so that the streaks of different colors of the repairing agent and curing agent components in the mixture completely disappear until a smooth mixture with the same color appears, and...

Embodiment 3

[0084] (1) Select the smear material, select the repair agent for metal repair, select the curing agent for bonding, the curing agent is 200 low molecular weight polyamide, and the amine value is 230~260mg KOH / g;

[0085] (2) Surface treatment, use a polishing tool to polish the cavitation part of the flow-passing part, remove all impurities in the cavitation pit with acetone, and reveal the metallic luster, clean the polished surface with a detergent, and leave no dust and impurities on the surface, and dry the surface;

[0086] (3) Prepare the mixing agent, mix the repairing agent in step 1 with the curing agent, the weight ratio of the repairing agent and the curing agent is 7:1, use a stirring and rolling device to prepare the The mixture is continuously stirred and rolled in one direction, so that the streaks of different colors of the repairing agent and curing agent components in the mixture completely disappear until a smooth mixture with the same color appears, and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com